Are you struggling to decide between a CNC lathe or CNC milling machine for your manufacturing needs? The wrong choice could lead to inefficiency, higher costs, or even production delays. But with a clear understanding of their capabilities, you can make an informed decision that optimizes your operations and maximizes output.

Direct Answer:

CNC lathes are ideal for cylindrical parts, while CNC milling machines excel at complex shapes and intricate features. Choose based on your part geometry and production requirements.

What Is a CNC Lathe?

A CNC lathe is a machine used for creating cylindrical parts. It works by rotating the workpiece against stationary cutting tools to remove material and shape the object.

Key Components:

- Chuck: Holds the workpiece securely.

- Spindle: Rotates the workpiece.

- Tool Turret: Houses multiple cutting tools for various operations.

- Control Panel: Manages the machine’s programmed instructions.

Common Operations:

- Turning: Creating cylindrical shapes.

- Threading: Cutting screw threads.

- Boring: Enlarging holes.

- Facing: Flattening the face of a workpiece.

Ideal For:

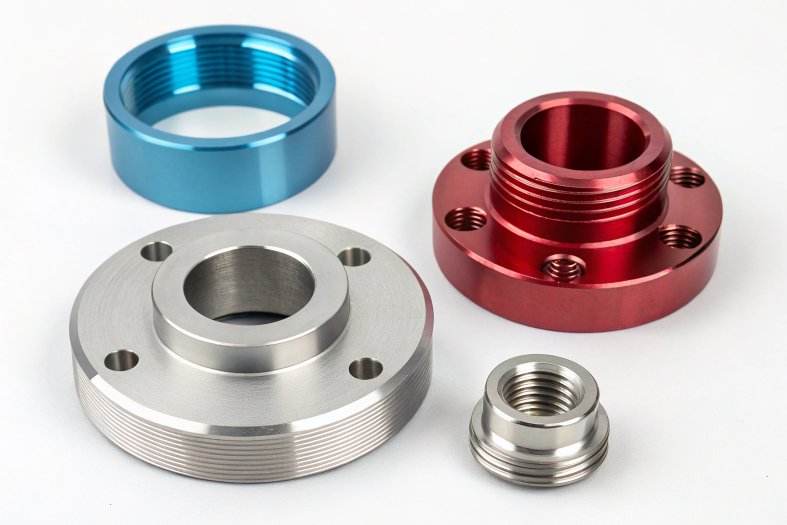

Parts like shafts, bushings, and screws that require rotational symmetry.

What Is CNC Milling?

CNC milling is a process where rotary cutting tools remove material from a stationary workpiece to create complex shapes and designs.

Key Components:

- Spindle: Rotates the cutting tool.

- Worktable: Holds the workpiece in place.

- Cutting Tools: Perform operations like drilling and contouring.

- Control Panel: Executes the programmed machining instructions.

Common Operations:

- Drilling: Creating holes in the material.

- Slotting: Cutting grooves or slots.

- Contouring: Shaping the material’s surface.

- 3D Shaping: Producing intricate designs.

Ideal For:

Parts with complex geometries, such as molds, aerospace components, and prototypes.

Key Differences Between CNC Lathes and CNC Milling Machines

| Aspect | CNC Lathe | CNC Milling |

|---|---|---|

| Workpiece Movement | Rotates the workpiece | Workpiece is stationary; tools rotate |

| Tool Movement | Stationary cutting tools | Moving cutting tools |

| Shapes Produced | Cylindrical or symmetrical parts | Complex, non-symmetrical parts |

| Speed | Typically faster for simple parts | Slower due to intricate operations |

| Versatility | Limited to specific geometries | Handles a wide range of designs |

Advantages of CNC Lathes

- Speed: Faster machining for cylindrical parts due to the rotating workpiece.

- Ease of Use: Simpler programming and setup for basic operations.

- Cost-Effective: Ideal for high-volume production of symmetrical components.

- Examples: Bolts, nuts, shafts, and pulleys.

Advantages of CNC Milling

- Complexity: Superior for complex geometries and intricate designs.

- Versatility: Works with a wide range of materials and shapes.

- Prototyping: Ideal for custom parts and low-volume production.

- Examples: Aerospace components, molds, and enclosures.

Which Is Better for Specific Applications?

CNC Lathe Is Better If:

- The part is cylindrical or symmetrical.

- High-speed production of simple shapes is required.

- Cost-effectiveness is a priority for high volumes.

CNC Milling Is Better If:

- The design involves complex geometries or 3D shapes.

- Flexibility is required for prototyping or small batches.

- The part has intricate features like slots, holes, or contours.

Factors to Consider When Choosing

- Part Geometry: Symmetrical designs favor lathes; complex shapes favor milling.

- Production Volume: Lathes are cost-effective for high volumes, while milling excels in versatility for small batches.

- Material: Some materials are easier to machine with one type of machine.

- Cost: Consider both setup and operational costs.

- Lead Time: Evaluate how quickly the machine can produce parts.

Can CNC Lathes and Milling Machines Work Together?

Yes, CNC lathes and milling machines can complement each other in a production process:

- Use a CNC lathe for initial shaping, such as creating a cylindrical base.

- Follow up with a CNC milling machine for detailed features like slots, grooves, or complex contours.

This combination maximizes efficiency and precision, especially for complex projects.

Conclusion

So, here’s the deal—CNC lathes and CNC milling machines each have their sweet spots. If you’re looking to churn out symmetrical parts quickly and in large quantities, a CNC lathe is your go-to. But if you’re tackling something with intricate details or complex shapes, CNC milling is where it’s at.

At the end of the day, it’s all about what your project needs. If you’re scratching your head trying to figure out which one’s right, just give PROMACHINED a shout. We’re always here to chat and help you find the perfect solution for your machining needs!

FAQ

What are the disadvantages of a CNC lathe?

- Limited Shapes: CNC lathes are primarily designed for cylindrical or symmetrical parts, limiting their versatility.

- Higher Initial Costs: The machine and tooling setup can be expensive, especially for small-scale operations.

- Skilled Labor Required: Programming and operating CNC lathes require expertise.

- Material Wastage: Compared to additive methods, CNC lathes generate more material waste.

Which CNC programming is best?

- Manual Programming: Best for simple operations and quick setups. Requires learning G-code and the specific CNC system instructions. Ideal for small projects and deeper understanding.

- Automatic Programming: Uses software like NX, Mastercam, or Creo to generate G-code automatically. Best for complex parts, multi-axis machining, and saving time in production.

Recommendation: For beginners or simple tasks, manual programming is sufficient. For advanced designs, automatic programming software is the better choice.

What is the difference between CNC lathe and CNC milling?

- CNC Lathe:

- Rotates the workpiece against stationary cutting tools.

- Ideal for cylindrical or symmetrical parts.

- Common operations: Turning, threading, boring.

- CNC Milling:

- Uses rotary cutting tools to shape a stationary workpiece.

- Handles complex geometries and 3D shapes.

- Common operations: Drilling, slotting, contouring.

Is milling harder than lathe?

Yes, CNC milling is generally harder than CNC lathe due to:

- Complexity: Milling involves intricate movements of multiple axes, making it more challenging to program.

- Setup: Requires precise alignment of the workpiece and tools.

- Skills: Operators need a deeper understanding of tooling, speeds, and feeds for complex geometries.

- However, with proper training, both operations become manageable.