It's all about what moves.

- Lathe: The workpiece rotates, shaping round objects.

- Milling Machine: The cutter rotates, shaping complex designs on a stationary workpiece.

- Drill Press: A drill bit rotates, making holes in a stationary workpiece.

Simple as that!

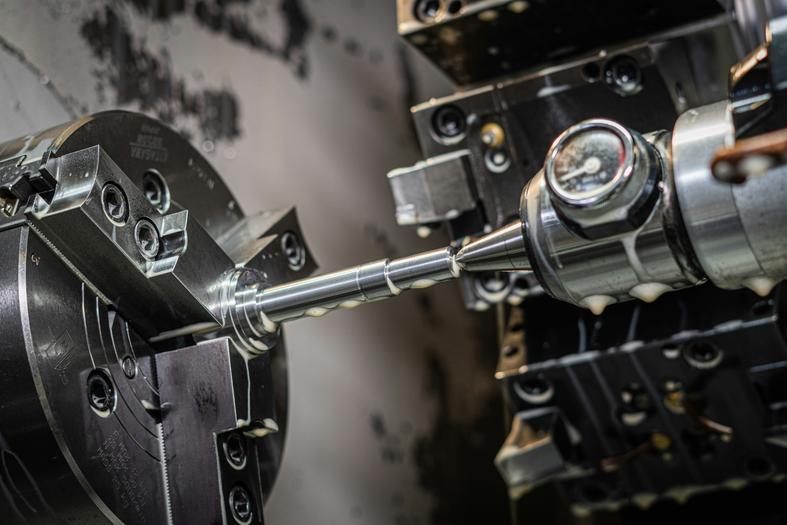

Lathe: The Master of Rotational Shaping

What is a lathe used for? A lathe is used to shape cylindrical or rotational workpieces by rotating them against a cutting tool.

How does a lathe work? The workpiece is held in a chuck and rotated on a spindle. A cutting tool is then brought into contact with the rotating workpiece to remove material.

Key Lathe Operations: Turning, facing, threading, parting (cut-off), and knurling.

Where are lathes used? Lathes are used in various industries, including automotive (crankshafts, axles), aerospace (turbine shafts), and manufacturing (custom parts, fasteners).

Milling Machine: Sculpting Complex Forms

What is a milling machine used for? A milling machine uses a rotating cutter to remove material from a stationary workpiece, creating complex shapes, slots, and other intricate details.

How does a milling machine work? The workpiece is secured to a worktable, and a rotating cutter, held in a spindle, is moved along multiple axes (X, Y, and Z) to shape the part.

Key Milling Operations: Face milling, end milling, contouring, drilling, and boring.

Where are milling machines used? Milling machines are crucial in tool and die making, mold making, aerospace (complex components), and the production of medical devices and electronics.

Drill Press: The Hole-Making Expert

What is a drill press used for? A drill press is designed for drilling precise holes in various materials.

How does a drill press work? A drill bit is held in a chuck and rotated while being brought down vertically onto a stationary workpiece to create a hole.

Key Drill Press Operations: Drilling, countersinking, counterboring, and tapping.

Where are drill presses used? Drill presses are commonly used in woodworking, metalworking, fabrication, construction, and even geological exploration.

Detailed Comparison Table

| Feature | Lathe | Milling Machine | Drill Press |

|---|---|---|---|

| Working Principle | Workpiece rotates, cutting tool moves | Cutter rotates, workpiece moves or is fixed | Drill bit rotates, vertical feed |

| Primary Motion | Workpiece Rotation | Cutter rotation and linear movement | Drill bit rotation and vertical movement |

| Primary Use | Shaping cylindrical parts | Shaping complex parts, milling, drilling | Drilling holes |

| Typical Operations | Turning, facing, threading, parting, knurling | Milling, drilling, boring, contouring | Drilling, reaming, tapping, countersinking |

| Workpiece Holding | Chucks, fixtures | Worktable, vises, fixtures | Worktable, vises |

| Tool Movement | Usually moves along one axis | Moves along three axes (X, Y, Z) | Vertical movement |

| Machining Characteristics | Suitable for shafts, discs, high efficiency | Wide applicability, can machine complex surfaces | High precision, suitable for precise holes |

| Applicable Materials | Metals, plastics, wood, etc. | Metals, plastics, wood, composites, etc. | Metals, plastics, wood, etc. |

| Precision | Relatively high | Relatively high | High |

| Complexity | Relatively simple | Relatively complex | Relatively simple |

| Cost | Moderate | Higher | Lower |

| Safety Precautions | Prevent workpiece ejection, tool breakage | Prevent cutter ejection, workpiece loosening | Prevent drill bit breakage, workpiece rotation |

| CNC Applications | CNC Lathe - High-precision turning, CNC Turning Centers | CNC Milling Machine - 3/Multi-axis machining, CNC Machining Centers | CNC Drill Press - Automated drilling, deep hole drilling |

Frequently Asked Questions (FAQ)

Q: What is the main difference between a lathe and a mill?

A: In a lathe, the workpiece rotates; in a mill, the cutting tool rotates.

Q: Can a milling machine do what a lathe does?

A: While some limited turning is possible on a mill with specialized tooling, a lathe is far more efficient and versatile for creating cylindrical parts.

Q: Can a drill press be used for milling operations?

A: No, a drill press is designed for vertical drilling only. Milling operations require movement along multiple axes and impose lateral forces that a drill press isn't designed to handle. This makes it dangerous and can cause damage.

Q: What does CNC stand for in machining?

A: CNC stands for Computer Numerical Control, which uses computer programs to automate machining operations with high precision and repeatability. CNC machines, including CNC lathes, CNC mills, and CNC drill presses, are widely used in modern manufacturing.

Q: What materials are commonly machined on these machines?

A: These machines can handle various materials, including metals (steel, aluminum, brass), wood, plastics, and composites, making them versatile tools for various applications.

Join the Conversation!

Have you ever worked with a lathe, milling machine, or drill press? We'd love to hear about your experiences! Share your thoughts or ask any questions you have in the comments below. Whether you're a pro or just getting started, feel free to join the conversation—let's learn from each other!