In CNC machining, traditional three-axis systems are increasingly unable to meet the demands of more complex part designs. As technology evolves, many manufacturers are turning to four-axis CNC machines, which not only boost production efficiency but also offer greater flexibility and precision for intricate parts. If you're looking for a solution to enhance production capabilities and handle more complex geometries, understanding the fourth axis in CNC machines is essential.

Direct Answer:

A fourth axis on a CNC machine adds a rotary axis, typically rotating around the X, Y, or Z axis. This allows for machining parts from multiple angles, improving efficiency and enabling the creation of more complex parts.

What is the Fourth Axis?

The fourth axis in CNC machining refers to a rotational axis that adds a new dimension of movement to the standard three linear axes. This axis is often referred to as the "A" axis, and it allows the workpiece to rotate around one of its axes, usually the X or Y axis. The introduction of the fourth axis enables the CNC machine to access additional angles, improving the overall versatility and precision of machining processes.

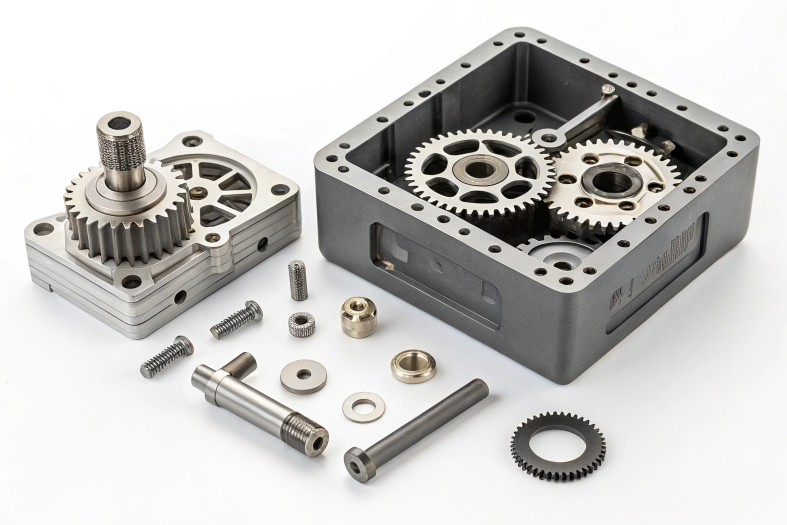

Unlike a traditional three-axis CNC machine, which only moves the workpiece or tool along linear paths, the fourth axis adds rotational motion. This allows for more intricate operations, such as drilling holes at angles, engraving complex shapes, and performing continuous cuts around cylindrical parts.

The Function of the Fourth Axis

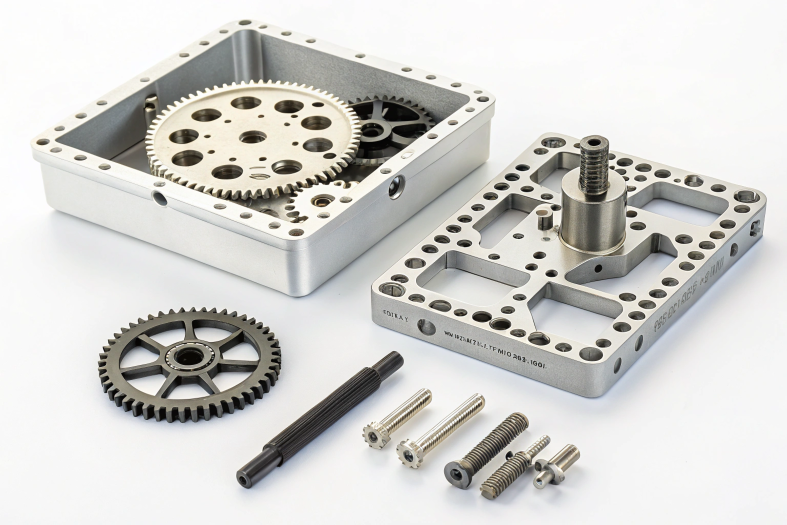

The primary function of the fourth axis is to introduce rotational motion, which expands the types of operations that can be performed without needing to reposition the workpiece manually. The fourth axis works in conjunction with the three linear axes (X, Y, and Z), allowing the tool to access different angles and surfaces of the workpiece with precision.

For example, with the addition of a fourth axis, a CNC machine can create features like complex slots or holes on a cylindrical surface without the need for additional setups. This is especially useful for parts that require operations on multiple sides, such as automotive components or aerospace parts, where precision is critical.

Moreover, the fourth axis helps improve machining efficiency by reducing the need for manual intervention or secondary operations. Parts can be machined continuously in a single setup, which reduces production time and increases overall throughput.

How Does the Fourth Axis Work?

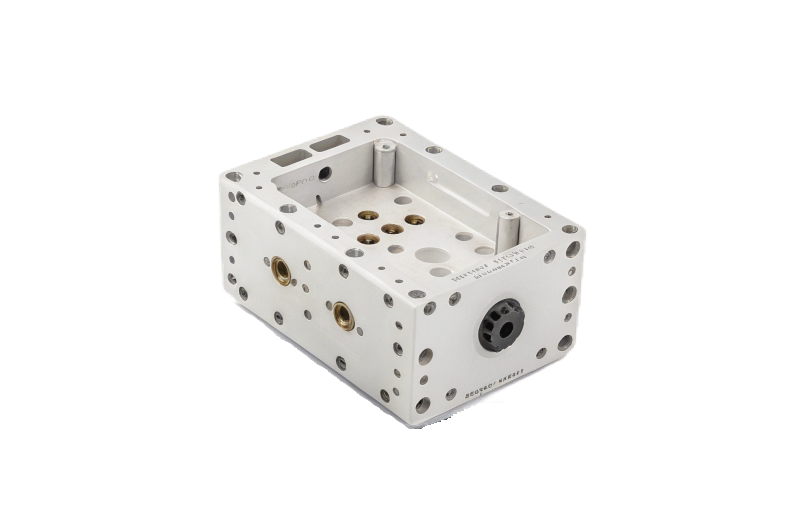

In a typical CNC machine, the workpiece is held in place while the cutting tool moves along the three linear axes. With the fourth axis, the workpiece is mounted on a rotary table, which allows it to rotate around the X, Y, or Z axis. This rotational movement enables the tool to access different angles of the part without the need to reorient the workpiece manually.

For instance, if you're machining a complex part with multiple surfaces, the fourth axis allows the tool to rotate the part to each surface, ensuring precision and reducing setup time. This means that a single CNC program can handle the entire machining process, reducing the need for multiple setups or manual interventions.

An example of the fourth axis in action is when machining a turbine blade. The blade needs to be cut from multiple angles, and with the fourth axis, the CNC machine can rotate the blade into position, allowing for cuts along its complex curvature.

Applications of the Fourth Axis

The fourth axis is particularly useful in industries that require high precision and complex part designs, such as automotive, aerospace, and medical device manufacturing.

- Automotive Industry: The fourth axis is commonly used to machine engine components, transmission parts, and other intricate automotive parts that require multi-angle machining in a single setup.

- Aerospace: In aerospace, components like turbine blades, brackets, and housings require precise cuts from multiple angles, making the fourth axis indispensable.

- Medical Devices: For medical implants or surgical instruments, where precision is paramount, the fourth axis allows for efficient and accurate multi-surface machining.

By adding the fourth axis, CNC machines can create these complex geometries more efficiently and accurately, reducing the need for re-clamping or manual repositioning of the parts.

Types of Fourth Axes

There are different types of fourth axes used in CNC machines, and the choice of axis depends on the machine's design and the workpiece's requirements.

- Horizontal Fourth Axis: The workpiece is mounted on a horizontal rotary table. This setup is ideal for parts that need to be rotated in the horizontal plane, such as certain automotive or aerospace components.

- Vertical Fourth Axis: The workpiece is mounted on a vertical rotary table. This setup is often used for smaller parts or when a specific orientation is required for the machining process.

- Fixed vs. Adjustable Fourth Axes: Fixed fourth axes are set at a specific angle, while adjustable fourth axes can rotate to different positions, providing more flexibility for complex parts.

Advantages of Using the Fourth Axis

The addition of the fourth axis provides several key advantages:

- Increased Production Efficiency: With the ability to machine multiple surfaces without repositioning the part, production cycles are shortened, leading to faster turnaround times.

- Higher Precision: The fourth axis enables the machining of intricate features with better precision, as the workpiece is not removed and re-clamped during the process.

- Complex Part Designs: The fourth axis allows for the creation of more complex part geometries, reducing the need for secondary operations or multiple setups.

Challenges and Limitations of the Fourth Axis

While the fourth axis offers many benefits, there are also some challenges:

- Higher Operator Skill Requirements: The added complexity of the fourth axis requires operators to have specialized training and expertise to use it effectively.

- Increased Machine Costs: CNC machines with a fourth axis are more expensive due to the added components and capabilities. Additionally, maintenance costs can be higher.

- Limited by Machine Size: Not all CNC machines are equipped to handle a fourth axis, and certain machines may require modifications to incorporate it.

Conclusion

In summary, the fourth axis significantly enhances the capabilities of CNC machines, allowing for more precise and efficient machining of complex parts. Whether you're manufacturing automotive components, aerospace parts, or medical devices, the fourth axis provides the flexibility to produce intricate designs in a single setup.

However, before integrating a fourth axis into your CNC operations, it's important to consider factors such as machine compatibility, operator training, and cost. For industries requiring high-precision and multi-surface machining, the fourth axis is an invaluable tool that can greatly improve both efficiency and part quality.

FAQ

1. What is the difference between 3 and 4 axis CNC?

A 3-axis CNC machine moves along three linear axes: X (left-right), Y (front-back), and Z (up-down). It is limited to machining flat or simple parts on one face at a time.

A 4-axis CNC machine adds a rotational movement around one of the axes (usually the X or Y axis), allowing the workpiece to rotate and enabling machining on multiple sides of the part without repositioning. This provides more flexibility and efficiency for complex parts.

2. What are the axes of a CNC machine?

The basic axes of a CNC machine are:

- X-axis: Left to right.

- Y-axis: Front to back.

- Z-axis: Up and down.

In machines with additional axes, such as a 4-axis or 5-axis machine, additional rotational movements are included:

- 4th Axis (A-axis): Rotates around the X or Y-axis.

- 5th Axis (B or C-axis): Rotates around the Z or X/Y axes, adding more versatility for complex part machining.

3. What is the difference between 4 axis and 5 axis CNC machine?

The main difference between a 4-axis and 5-axis CNC machine is the additional axis of movement:

- A 4-axis CNC machine adds one rotational axis (the 4th axis) to the traditional three linear axes.

- A 5-axis CNC machine has two rotational axes, offering even more flexibility. This allows the tool to approach the part from almost any angle, reducing the need for repositioning and enhancing precision.

A 5-axis machine is ideal for highly complex parts with intricate features, whereas a 4-axis machine can handle moderately complex parts but may require more setups for some geometries.

4. Is a 4th axis worth it?

A 4th axis is definitely worth it if your production involves parts that require machining on multiple sides or at various angles. It can improve precision, efficiency, and complexity of your machining operations, reducing the need for manual re-clamping or multiple setups.

However, if your parts are simple or flat, the additional cost and complexity of the 4th axis may not be justified. Evaluate your needs based on part complexity, production volume, and machine compatibility to decide if it's a good investment.