CNC machining, while precise and efficient, can be costly and time-consuming, especially for complex designs or small production runs. Many industries find it essential to explore alternatives that reduce costs, increase flexibility, or speed up prototyping. Technologies like 3D printing, injection molding, laser cutting, and water jet cutting offer unique advantages, such as reduced material waste, faster production, and better suitability for specific materials and shapes, making them effective alternatives to CNC machining.

Direct Answer:

The main alternatives to CNC machining include 3D printing, injection molding, laser cutting, and water jet cutting. Each provides unique benefits like cost-effectiveness, faster production, and suitability for specific material requirements.

Traditional Manufacturing Methods

Casting

Casting is one of the oldest manufacturing processes, involving pouring molten material (typically metal) into a mold to form a part. After the material solidifies, it is removed from the mold, often requiring additional processes to achieve the desired finish.

When to Use Casting:

Casting is ideal for parts that are large, complex, or require a high level of mass production, such as engine blocks, large housings, and heavy-duty machinery parts.

Advantages:

- Cost-Efficient for High Volumes: Once the mold is created, casting allows for large quantities of identical parts to be produced at a low cost.

- Design Freedom: Casting allows the creation of parts with complex geometries that would be difficult or expensive to achieve with CNC machining, such as intricate internal structures.

- Material Variety: Casting can be used for a wide variety of metals, including aluminum, steel, and alloys, making it versatile for different industries.

Disadvantages:

- Precision Limitations: While casting can handle complex geometries, it doesn’t achieve the high precision of CNC machining. Parts often require additional machining or finishing.

- Material Waste: The casting process can lead to material wastage, especially if there are excess components or imperfections in the casting.

- Slow Setup Time: The initial investment in molds and tooling can be significant, especially for low-volume production.

Casting can be a great alternative for producing large, heavy, or geometrically complex parts where precision is not the top priority. However, if high precision is required, you may need to budget for additional machining steps to meet tight tolerances.

Forging

Forging involves shaping metal using compressive forces, often applied with a hammer or press. The process enhances the material's strength by aligning its grain structure.

When to Use Forging:

Forging is best suited for parts that need to withstand high stress and wear, such as gears, shafts, and structural components used in aerospace and automotive applications.

Advantages:

- Superior Strength: Forged parts are often stronger and more durable than cast parts because the material is compressed, improving its structural integrity.

- Fewer Defects: The forging process results in fewer internal defects (voids, cracks), making it ideal for mission-critical applications where reliability is essential.

- Better Material Properties: Forging can enhance specific material properties, such as toughness and fatigue resistance.

Disadvantages:

- Material Limitations: While forgings are ideal for certain metals, like steel and titanium, it’s not always feasible for highly intricate or delicate geometries.

- High Initial Costs: Forging requires expensive tooling, and thus, it’s more suitable for medium to high-volume production runs.

If you're working with materials that require extreme strength or fatigue resistance (like parts for aircraft or high-performance vehicles), forging might be the best choice. However, if part complexity exceeds certain limits, additional processing may be required to achieve the desired final shape.

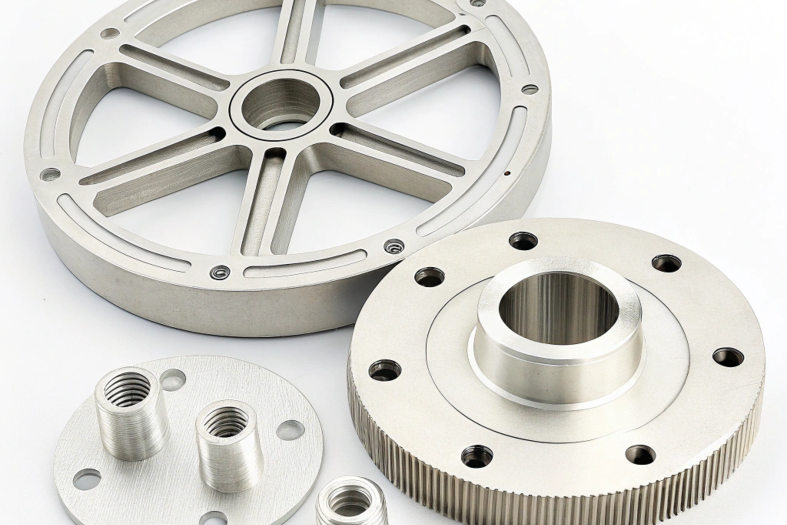

Milling

Milling is a subtractive manufacturing process that involves removing material from a workpiece using rotating tools. While traditional milling is less automated than CNC machining, it can still be effective for specific applications.

When to Use Milling:

Milling is ideal for creating flat surfaces, slots, and intricate designs on small to medium-sized parts. This method is often used for components that don't require the extreme precision of CNC machining.

Advantages:

- Simple and Versatile: Milling can be used to create a variety of geometries, from basic to moderately complex.

- Lower Cost for Small Batches: If you only need a small number of parts, traditional milling might be a more affordable option compared to investing in CNC machinery.

Disadvantages:

- Lower Precision: Milling typically lacks the precision of CNC machining, especially when dealing with complex geometries.

- Higher Labor Requirements: Manual milling requires skilled labor, and there's a higher chance for human error than with fully automated CNC machines.

If your project is a low-volume run with less complex geometries, traditional milling might be a cost-effective solution. However, for parts that demand high precision or intricate features, CNC machining or one of the other alternatives might be a better fit.

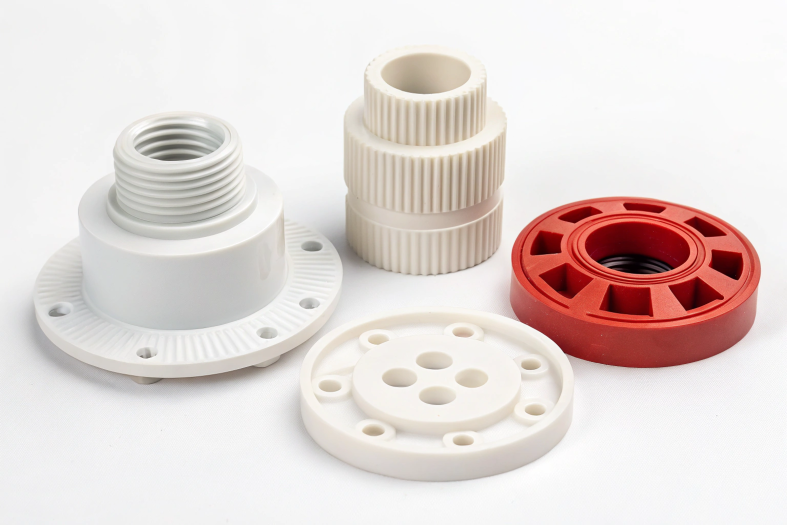

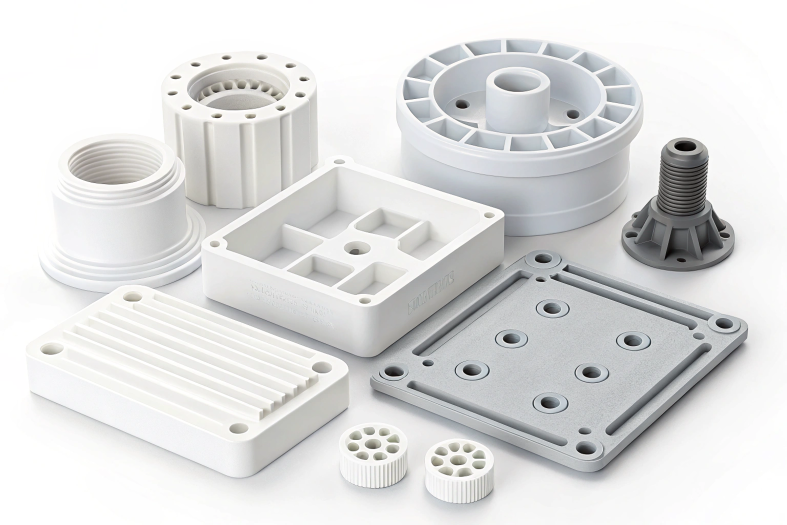

Additive Manufacturing (3D Printing)

Types of 3D Printing

Additive manufacturing has taken the industry by storm, offering new possibilities for rapid prototyping, custom part production, and small-batch manufacturing. 3D printing works by building parts layer by layer, eliminating the need for complex molds or tooling.

- SLA (Stereolithography): Uses ultraviolet light to solidify liquid resin. SLA is perfect for creating highly detailed, smooth parts, often used for prototypes and small production runs.

- FDM (Fused Deposition Modeling): FDM uses a heated nozzle to extrude melted plastic filament layer by layer. It’s the most common type of 3D printing, ideal for producing durable parts for prototyping and small runs.

- SLS (Selective Laser Sintering): SLS uses a laser to fuse powdered materials (often metal or plastic) into solid parts. It’s widely used in aerospace and automotive industries for creating high-strength, complex parts.

Advantages:

- Rapid Prototyping: 3D printing allows for fast iteration, making it an excellent choice for product development.

- Design Flexibility: Complex geometries and internal structures are easier to create without the need for traditional tooling.

- Low Waste: Since material is added layer by layer, there is minimal waste, making it an environmentally friendly option.

Disadvantages:

- Material Limitations: While the selection of materials is growing, most 3D printing technologies do not offer the same strength, thermal stability, or surface finish as CNC machining.

- Slower than CNC for High-Volume Production: Although 3D printing is fast for prototyping, it’s typically slower and more expensive than CNC machining for large-scale production.

3D printing is ideal for rapid prototyping and small, custom parts that might be too complex or costly to produce with traditional methods. However, for large production volumes or parts requiring high strength, CNC machining is likely a better choice.

Laser Cutting

How Laser Cutting Works

Laser cutting involves using a focused laser beam to cut through materials with precision. This method is primarily used for materials like metals, plastics, and wood.

When to Use Laser Cutting:

Laser cutting is ideal for creating parts with precise edges and intricate designs, often used in industries like electronics, automotive, and signage.

Advantages:

- Precision and Speed: Laser cutting offers excellent precision and can cut thin materials quickly.

- Clean Cuts: The process generates minimal material waste and doesn't require additional finishing, as laser cuts are smooth and precise.

- Minimal Tooling Costs: Unlike CNC machining, laser cutting doesn’t require specialized tooling or molds.

Disadvantages:

- Thickness Limitations: Laser cutting works best with thinner materials. Cutting thicker materials may require higher-powered lasers and increase costs.

- Not Suitable for 3D Shapes: While laser cutting can create precise 2D cuts, it cannot produce 3D features.

Laser cutting is a fast, cost-effective solution for high-precision, 2D cuts, especially for applications that require intricate designs or fine edges. It is, however, limited by material thickness and geometric complexity.

Waterjet Cutting

Process Overview

Waterjet cutting uses high-pressure water (sometimes mixed with abrasives) to slice through a variety of materials. It’s highly effective for cutting metals, stone, and glass without generating heat.

When to Use Waterjet Cutting:

Waterjet cutting is ideal for cutting thick, hard materials where heat distortion is not acceptable, such as titanium in aerospace components or stone in architecture.

Advantages:

- No Heat-Affected Zone: Waterjet cutting doesn’t cause heat distortion, making it ideal for materials sensitive to temperature.

- Material Versatility: It can cut metals, plastics, ceramics, and even food, offering incredible versatility.

- Clean Cuts: Waterjet cutting provides smooth cuts with little to no burrs, reducing the need for secondary finishing.

Disadvantages:

- Slower than CNC: Waterjet cutting tends to be slower than CNC machining, especially for large batches.

- Material Limitations: While it can cut a variety of materials, it is typically limited to relatively soft to moderately hard materials.

If you need to cut thick materials or sensitive materials without introducing heat distortion, waterjet cutting is a great option. It’s especially useful for the aerospace, automotive, and architecture industries, but may not be suitable for all part types.

Conclusion:

As we've seen, each manufacturing method has its strengths and weaknesses. To select the right one for your project, consider factors like:

- Part Complexity: 3D printing, laser cutting, and waterjet cutting excel with complex geometries.

- Volume: For high-volume production, consider casting, forging, or traditional milling.

- Material Requirements: Choose the process that best suits your material, whether it's a high-strength metal, a delicate plastic, or an abrasive material.

- Precision: CNC machining, EDM, and laser cutting are all excellent choices for parts that demand high precision.

Each method has its place in modern manufacturing. By understanding the trade-offs, you can make informed decisions that will optimize your project’s cost, efficiency, and outcome.

FAQ:

What is the alternative to a CNC machine?

Several alternatives to CNC machining include:

- Traditional Manufacturing Methods: Casting, forging, and milling can replace CNC for specific applications, especially for high-volume production or when dealing with complex geometries.

- Additive Manufacturing (3D Printing): Ideal for rapid prototyping and small batch production, especially for custom or intricate designs.

- Laser Cutting: Best for precision cutting of thin materials like metals and plastics.

- Waterjet Cutting: Offers precise cuts without heat distortion, especially useful for thick or heat-sensitive materials.

- Electrical Discharge Machining (EDM): Used for extremely precise cutting, especially for hard metals and detailed features.

What is the difference between CNC and DMLS?

-

CNC (Computer Numerical Control): A subtractive manufacturing process that removes material from a workpiece using rotating tools. It’s widely used for producing parts with high precision and tight tolerances.

-

DMLS (Direct Metal Laser Sintering): An additive manufacturing process that uses a laser to sinter powdered metal, building up parts layer by layer. It's ideal for producing complex geometries and custom metal parts without the need for tooling.

Key Differences:

- Process Type: CNC is subtractive (removes material), while DMLS is additive (builds up material layer by layer).

- Material: CNC can work with a wide variety of materials, including metals, plastics, and composites, whereas DMLS is mainly used for metal alloys.

- Complexity: DMLS can create more complex geometries and internal structures than CNC machining, but CNC machining generally offers superior surface finish and precision.

Is there a future in CNC machining?

Yes, CNC machining has a bright future due to its continuous improvements in precision, automation, and material capabilities. With the increasing demand for high-precision parts in industries like aerospace, medical devices, and automotive, CNC machining remains essential. Advances in AI, IoT integration, and multi-axis CNC machines are pushing the boundaries of what’s possible, making CNC machining a critical technology for the future of manufacturing.

Is waterjet cheaper than CNC?

The cost comparison between waterjet cutting and CNC machining depends on the specific project:

-

Waterjet Cutting: Generally more cost-effective for cutting thick or heat-sensitive materials, with low material wastage. However, it can be slower for intricate or fine detail work compared to CNC.

-

CNC Machining: Typically faster and more precise for complex geometries and smaller, high-precision parts. However, the initial setup cost for CNC machines can be higher, and material waste can be a consideration for certain jobs.

In summary, waterjet cutting may be cheaper for simple, thick material cuts, but CNC machining may provide a better cost-to-performance ratio for high-precision or intricate work.