Ensuring product quality and consistency is essential in manufacturing, but let’s face it—production processes can sometimes go off track. If issues aren’t caught early, they can snowball into wasted resources, customer complaints, or even contract penalties. That’s where First Article Inspection (FAI) comes in. It’s a crucial step to verify that everything is on point before full-scale production begins.

Definition of First Article Inspection

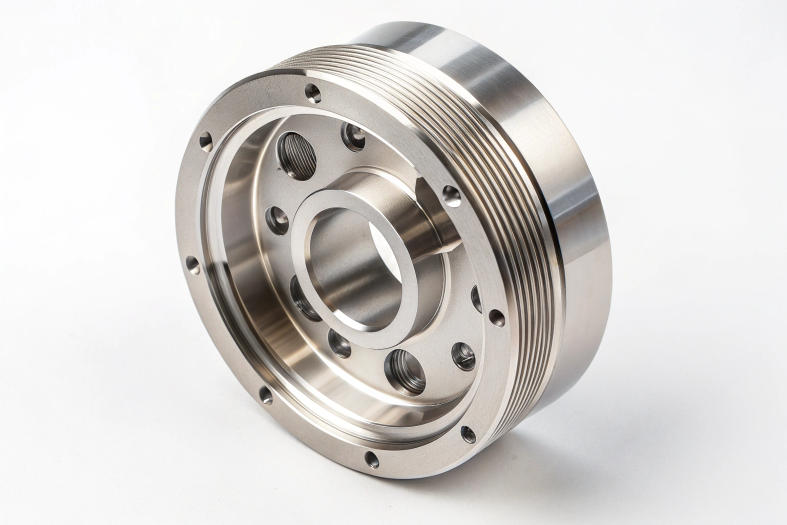

First Article Inspection (FAI) is a rigorous quality control process conducted on the initial part or assembly manufactured. It involves comprehensive dimensional checks, material validation, and process verification to ensure the output matches design requirements. FAI is not just about measurement but also about evaluating the manufacturing process itself, identifying bottlenecks, and confirming that production is stable before full-scale manufacturing begins.

Key aspects include:

- Dimensional Accuracy: Ensures every feature conforms to the CAD model or technical drawing.

- Material Certification: Verifies that materials used meet specifications, often through third-party lab tests or supplier certifications.

- Process Verification: Confirms process parameters, such as feed rates, spindle speeds, and tolerances in CNC machining.

Purpose of First Article Inspection

FAI serves as a technical checkpoint to:

- Validate Manufacturing Processes: Analyze whether the machinery, tools, and operators can reliably produce parts to specification.

- Detect Deviations: Identify dimensional inaccuracies, material inconsistencies, or process inefficiencies early in the production lifecycle.

- Create a Reference Record: Document the initial inspection results as a baseline for ongoing quality checks.

- Optimize CNC Parameters: For example, confirming that a CNC lathe achieves specified tolerances (e.g., ±0.01 mm) without unnecessary rework or secondary operations.

Industries that Use First Article Inspection

FAI is critical in high-precision sectors, including:

- Aerospace and Defense: For verifying components like turbine blades and fuselage parts under AS9102 standards.

- Automotive: Ensures critical parts like engine pistons or braking systems meet stringent safety tolerances.

- Medical Devices: Validates the biocompatibility and precision of surgical instruments or implants.

- Electronics: Confirms micro-level tolerances in PCBs and semiconductor casings.

- Precision Engineering: Ensures that components like optical mounts or robotics gears meet nanometer-level specifications.

Key Elements of an FAI Report

A thorough FAI report includes:

- Dimensional Measurements: Data recorded using Coordinate Measuring Machines (CMMs) or laser scanners, ensuring micron-level accuracy.

- Material Verification: Validation using methods like spectrometry for alloy composition or tensile testing for mechanical strength.

- Process Data: Documentation of CNC parameters such as toolpath generation, coolant usage, and cycle time analysis.

- Functional Testing: Stress or fatigue tests to simulate operational conditions.

- Supporting Documentation: Including CAD drawings, Certificates of Conformance (CoC), and Process Flow Diagrams (PFDs).

For example, an FAI report for an aerospace bracket might detail:

- Hole position tolerances of ±0.05 mm.

- Surface roughness (Ra) of 1.6 µm measured using a profilometer.

- Material analysis confirming compliance with AMS 5643 (stainless steel specification).

When is First Article Inspection Performed?

FAI is conducted at critical milestones, such as:

- New Product Introduction (NPI): Validating CNC program outputs for a newly designed component.

- Engineering Change Orders (ECOs): Reconfirming specifications after altering dimensions or materials.

- Supplier Transitions: Ensuring consistency when moving production to a new CNC machining vendor.

- Production Resumption: Revalidating setups after a 6+ month production gap to account for potential machine calibration drift.

Benefits of First Article Inspection

- Precision Validation: Confirms tolerances such as ±0.002 mm for high-precision parts like bearings.

- Cost Savings: Early detection of tooling wear or setup errors prevents large-scale production waste.

- Regulatory Compliance: Meets industry standards like ISO 13485 for medical devices or AS9102 for aerospace.

- Process Improvement: Optimizes tool life, cutting speeds, and feeds for maximum efficiency.

Steps in the First Article Inspection Process

1. Preparation

- Gather design documents, GD&T (Geometric Dimensioning and Tolerancing) data, and material specs.

- Set up CNC machines with appropriate tools, such as tungsten carbide inserts for stainless steel.

2. Manufacturing the First Article

- Produce a single part using final production conditions, including optimized feed rates (e.g., 0.2 mm/rev for finishing cuts).

3. Dimensional Inspection

- Use CMMs for 3D measurements and height gauges for critical vertical dimensions.

- Validate hole tolerances with plug gauges or bore micrometers.

4. Material Analysis

- Conduct XRF (X-ray fluorescence) testing for alloy composition.

- Perform hardness testing to confirm mechanical properties.

5. Documentation

- Record results in an FAI report with annotated CAD models showing actual vs. nominal values.

- Highlight out-of-spec features and propose corrective actions.

6. Approval and Follow-Up

- Submit the report for customer review and approval.

- Implement feedback by adjusting CNC programming or re-calibrating equipment.

Standards Governing First Article Inspection

- AS9102: Specifies documentation requirements for aerospace FAI.

- ISO 9001: General quality management guidelines.

- ISO 10303: For digital exchange of product data, often used in FAI.

- IATF 16949: Automotive-specific requirements for part validation.

Challenges and Best Practices

Challenges

- Measurement Accuracy: Achieving ±0.001 mm precision for critical components.

- Documentation Overhead: Managing extensive data in complex assemblies.

- Communication Gaps: Ensuring clear technical feedback between suppliers and clients.

Best Practices

- Use Advanced Tools: Deploy automated measurement systems like 3D laser scanners for speed and precision.

- Calibrate Regularly: Ensure tools like micrometers and CMMs are calibrated to traceable standards.

- Train Staff: Provide FAI-specific training, particularly in interpreting GD&T symbols.

Conclusion

First Article Inspection is a cornerstone of high-precision manufacturing, ensuring that every product meets its intended design before mass production. By integrating advanced tools, rigorous processes, and adherence to standards, manufacturers can mitigate risks, enhance quality, and satisfy even the most demanding industries.

Additional Resources

FAQ:

What triggers a First Article Inspection?

FAI is typically triggered in the following scenarios:

- New Product Introduction (NPI): When manufacturing a new design for the first time.

- Design Changes: After modifying part dimensions, materials, or specifications.

- Supplier Changes: When switching suppliers or production facilities.

- Process Changes: Adjustments in manufacturing methods or tooling.

- Production Gaps: Restarting production after a long period (e.g., 8+ hours).

How many pieces are required for First Article Inspection?

Usually, one piece is sufficient for FAI. This piece is produced under standard production conditions and represents the quality of future parts. In some cases, additional samples may be inspected if the customer or industry standards require statistical validation.

How to do a First Article Inspection (FAI)?

- Prepare: Gather design specifications, technical drawings, and material certifications.

- Produce the First Article: Manufacture one sample using final production settings.

- Inspect Dimensions: Use tools like Coordinate Measuring Machines (CMMs) to measure all features against the design.

- Verify Materials: Perform tests like XRF for composition and tensile tests for strength.

- Test Functionality: Simulate operational conditions (e.g., load testing).

- Document Results: Create a detailed FAI report showing actual vs. nominal values.

- Submit for Approval: Share the report with the customer for review and sign-off.

Does the seller have the right to see the inspection report?

Yes, the seller (manufacturer or supplier) has the right to review the inspection report, especially if they conducted the FAI. Sharing the report ensures transparency and helps address any discrepancies before customer review.