You know how making super precise, complex parts can feel almost impossible with traditional tools? It’s so frustrating when things take forever and still don’t turn out right. That’s why CNC milling is such a game-changer—it’s like having a superpower for creating accurate, high-quality components quickly and efficiently.

Direct answer:

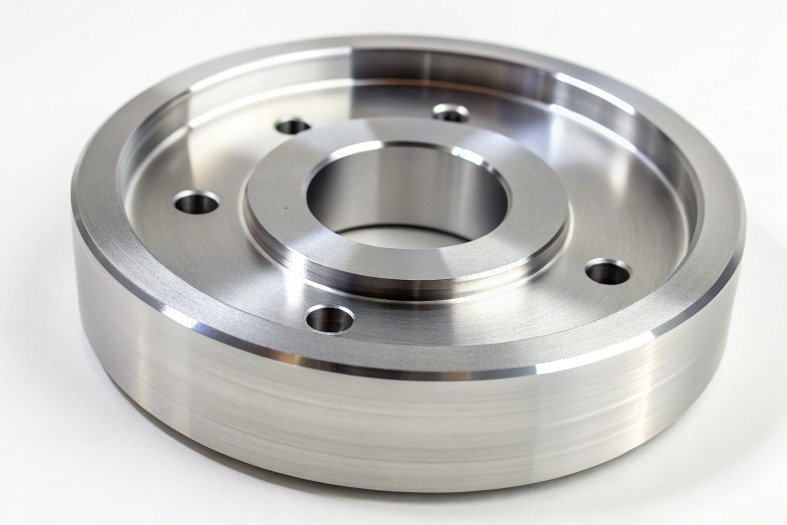

CNC milling is a manufacturing process that uses rotary cutting tools to remove material from a workpiece. The process is controlled by computer programming, ensuring high precision and repeatability. It’s a critical part of CNC (Computer Numerical Control) technology, which automates machining processes for better efficiency and accuracy.

Key Components of a CNC Milling Machine:

- Spindle: Rotates the cutting tool.

- Worktable: Holds the material being machined.

- Cutting Tools: Used to remove material (e.g., drills, end mills).

- Control Panel: Executes the programmed instructions.

CNC milling works with a wide range of materials, including metals like aluminum and steel, plastics such as ABS and PEEK, and even composites like carbon fiber.

How Does CNC Milling Work?

- Design Creation: A 3D model is created using CAD (Computer-Aided Design) software.

- Programming: The CAD design is converted into machine-readable instructions using CAM (Computer-Aided Manufacturing) software.

- Machine Setup: The workpiece is secured on the worktable, and the cutting tool is installed.

- Machining: The CNC milling machine follows the programmed instructions to remove material and shape the part.

- Post-Processing: The finished part is refined through deburring, polishing, or other finishing processes.

What Are the Types of CNC Milling Machines?

-

Vertical Milling Machines:

- Spindle is oriented vertically.

- Ideal for small to medium-sized parts.

- Common in prototyping and light production.

-

Horizontal Milling Machines:

- Spindle is oriented horizontally.

- Better for heavy-duty tasks and larger workpieces.

- Often used in automotive and aerospace industries.

-

Multi-Axis Milling Machines:

- 3-axis, 4-axis, and 5-axis machines allow machining from multiple angles.

- Perfect for complex geometries and advanced applications like turbine blades or medical implants.

What Are the Advantages of CNC Milling?

1. Precision and Accuracy

CNC milling can achieve tight tolerances, often within ±0.001 mm. This level of precision is crucial for industries like aerospace, where even the smallest deviation can impact performance.

2. Versatility

From metals to plastics, CNC milling accommodates a wide variety of materials and handles intricate designs with ease. It’s equally suited for prototypes and full-scale production.

3. Efficiency

Automation allows CNC milling to produce parts much faster than manual methods. Machines can run continuously, reducing downtime and increasing productivity.

4. Cost-Effectiveness

Despite higher upfront costs, CNC milling saves money in the long run by minimizing material waste, reducing labor costs, and enabling efficient high-volume production.

What Are the Applications of CNC Milling?

CNC milling is used across countless industries. Here are some examples:

- Aerospace: High-precision components like turbine blades.

- Automotive: Engine parts, gearboxes, and brake components.

- Medical: Custom implants, surgical tools, and diagnostic equipment.

- Electronics: Precision housings and connectors.

- Consumer Goods: Mold prototypes for product development.

What Are the Challenges of CNC Milling?

- Initial Costs: CNC machines require significant upfront investment.

- Skilled Labor: CAD/CAM programming and machine operation require expertise.

- Material Wastage: Compared to additive manufacturing methods like 3D printing, CNC milling generates more waste.

What Are the Future Trends in CNC Milling?

- Advancements in Multi-Axis Milling: 5-axis machines are becoming more accessible, enabling even greater flexibility for complex designs.

- AI and Machine Learning: These technologies are helping to optimize machining processes, reduce errors, and improve efficiency.

- Sustainability: Newer machines are designed to use less energy and produce less waste, aligning with global sustainability goals.

Conclusion

CNC milling is a powerful tool in manufacturing, offering unparalleled precision, versatility, and efficiency. From automotive to medical, its applications are vast and essential to modern industry. Whether you’re looking to prototype a new product or produce high-quality parts at scale, CNC milling has the capabilities to deliver.

If you’re ready to explore CNC milling for your next project, feel free to reach out to PROMACHINED for expert guidance and high-quality manufacturing solutions.

FAQ:

What is meant by CNC milling?

CNC milling is a manufacturing process where rotary cutting tools are used to remove material from a workpiece. The process is controlled by computer software, ensuring high precision and consistency. CNC stands for Computer Numerical Control, highlighting the automation of the operation.

What is the CNC milling process?

The CNC milling process involves the following steps:

- Design Creation: A 3D model is created using CAD (Computer-Aided Design) software.

- Programming: The design is converted into machine instructions with CAM (Computer-Aided Manufacturing) software.

- Machine Setup: The workpiece is secured, and the appropriate cutting tool is selected.

- Machining: The CNC machine follows programmed instructions to remove material and shape the part.

- Post-Processing: Additional steps like deburring or polishing refine the finished product.

What is the difference between CNC cutting and milling?

- CNC Cutting: A broader term encompassing any process that removes material, including laser cutting, plasma cutting, or waterjet cutting. These methods often cut along flat planes.

- CNC Milling: Specifically involves rotary cutting tools to shape material into complex 3D forms. Milling offers greater versatility for creating detailed and intricate designs.

Is CNC milling easy?

CNC milling can be easy for trained operators but requires:

- Technical Skills: Understanding CAD/CAM software and machine programming.

- Experience: Familiarity with tooling, materials, and machine setup.

- Learning Curve: Beginners may find it challenging initially, but with proper training and practice, CNC milling becomes manageable and highly efficient.