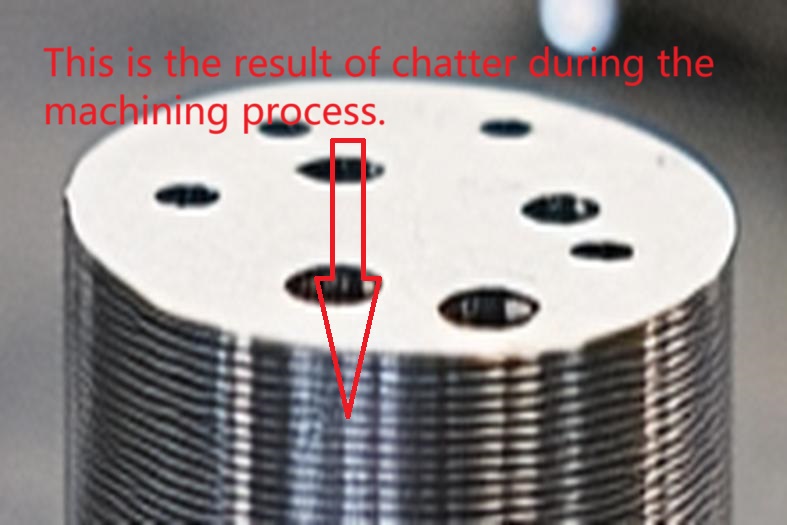

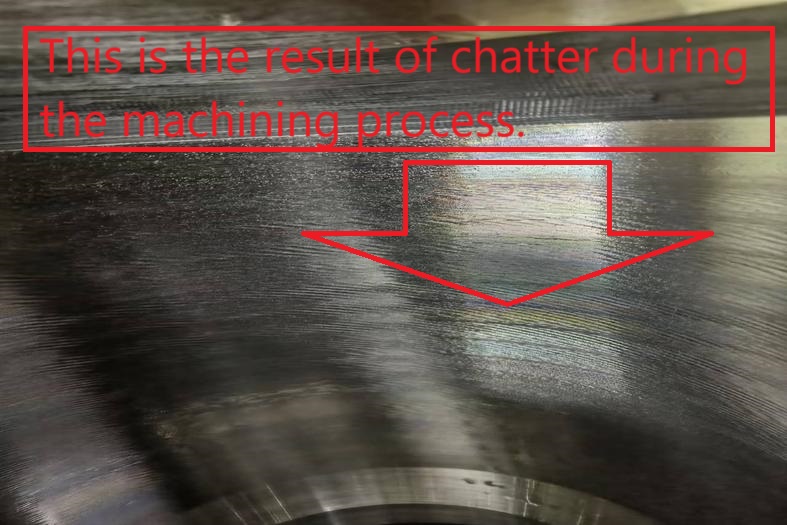

Chatter in CNC machining is a phenomenon where unwanted vibrations occur between the cutting tool and the workpiece, leading to a range of issues such as poor surface finishes, dimensional inaccuracies, and a reduction in tool life. These vibrations typically arise when cutting forces interact with the machine’s natural frequencies, causing oscillations that disrupt the machining process. To effectively mitigate chatter, manufacturers often adjust cutting parameters, enhance machine rigidity, and use advanced tooling technologies.

Key Causes of Chatter in Machining

Chatter is a complex problem caused by a variety of factors. In my experience, the following causes are the most common:

- Machine Rigidity: Insufficient machine rigidity allows vibrations to amplify, making it harder to control the cutting process.

- Cutting Parameters: Incorrect feed rates, spindle speeds, or cutting depths can lead to resonance, triggering vibrations.

- Tool Wear and Geometry: Dull tools or those with poor geometry exacerbate vibration problems, causing further instability.

- Material Properties: Harder materials like titanium or Inconel are more prone to generating excessive vibrations.

Addressing these causes requires a multifaceted approach to optimize machining conditions, improve the final product's quality, and increase overall efficiency.

Real-World Examples from My Experience

Automotive Precision and Vibration Control

A few months ago, I worked with an automotive parts manufacturer who was struggling with significant chatter during high-speed turning operations. The company was producing precision components for critical automotive applications, and they faced persistent challenges with inconsistent surface finishes and rapid tool wear.

After conducting a thorough inspection, we identified that the machine’s lack of rigidity was the primary issue. The cutting forces generated during the turning process were not being absorbed effectively, leading to unstable conditions. Here’s how we addressed the problem:

- Optimized Cutting Parameters: We adjusted the cutting speeds and feed rates to keep the machine’s natural frequency out of resonance, effectively reducing vibrations.

- Reinforced Machine Rigidity: We added vibration-damping materials to the machine structure, which significantly reduced the amplitude of the vibrations.

- Tool and Fixture Adjustments: High-performance, rigid tools with better geometry were introduced, along with stronger tool-holding systems to minimize deflection.

As a result of these changes, we saw:

- 40% increase in tool life

- 30% improvement in surface finish quality

- A substantial reduction in rework time, leading to cost savings and a more stable production environment.

This case illustrates the effectiveness of addressing both machine rigidity and cutting parameters to tackle chatter and improve manufacturing outcomes.

Aerospace Component Manufacturing: A Focus on Precision

Another project I worked on involved an aerospace component manufacturer who was experiencing significant chatter while machining turbine blades for jet engines. These parts are extremely critical, as even minor defects or dimensional inaccuracies could lead to catastrophic failures.

After analyzing the situation, I discovered that the cutting forces and the machine’s natural frequency were resonating, amplifying the vibrations. To resolve this, we took the following steps:

- Spindle Speed Adjustment: We fine-tuned the spindle speed to avoid resonance, ensuring a smoother and more controlled cutting motion.

- Toolholder Upgrade: The standard toolholder was replaced with a high-rigidity version, which provided better vibration damping.

- Optimized Cutting Depths: By reducing the cutting depth, we minimized the forces acting on the machine, preventing the onset of chatter.

The results were remarkable:

- 25% improvement in dimensional accuracy

- 40% reduction in part rejection rates

- Increased machining efficiency, enabling the manufacturer to meet strict aerospace tolerances without compromising production speed.

This project highlights how understanding the root causes of chatter and implementing a systematic approach to address them can drastically improve both precision and productivity.

Medical Device Manufacturing: Ensuring Surface Integrity

One of the most critical projects I worked on involved a medical device manufacturer facing severe chatter issues while milling custom implants. These implants required strict surface finish and dimensional accuracy standards, as any defects could jeopardize patient safety.

We quickly identified that the lack of rigidity in the CNC machine was causing vibrations, which affected both the surface finish and the dimensional accuracy of the implants. To address this, we implemented the following solutions:

- Vibration-Damping Systems: Advanced vibration-damping technologies were installed on the machine to stabilize the machining process.

- Cutting Parameter Optimization: We optimized the cutting speeds and feed rates to ensure a smooth cutting action while reducing the risk of resonance.

- High-Performance Tooling: We recommended switching to vibration-resistant tooling with better geometric design, which helped reduce tool deflection and improve surface integrity.

The improvements were immediate:

- Surface roughness reduced by 30%

- Implant accuracy improved by 15%, ensuring the parts met the stringent safety standards required in the medical field.

This case is a great example of how, with the right combination of technology and process optimization, manufacturers can significantly improve both product quality and production efficiency in highly regulated industries like medical device manufacturing.

Key Takeaways for Avoiding Chatter in Machining

From these real-world examples, I’ve distilled several key takeaways that can help avoid chatter and improve machining processes:

- Optimize Cutting Parameters: Adjusting cutting speeds, feed rates, and depths of cut is crucial to avoiding resonance and minimizing vibrations.

- Improve Machine Rigidity: Reinforcing the machine tool with vibration-damping materials is one of the most effective ways to reduce chatter.

- Use High-Performance Tooling: Selecting rigid, well-designed tools ensures more stable cutting and minimizes tool deflection.

- Continuous Testing and Adjustment: Regular testing of cutting conditions and adjustments based on material and tooling conditions help maintain optimal machining performance.

- Implement Vibration-Damping Technologies: Passive and active damping systems can absorb unwanted vibrations, stabilizing the machining process and improving part quality.

Frequently Asked Questions (FAQ)

Q: What is chatter in machining?

A: Chatter refers to unwanted vibrations between the cutting tool and the workpiece, which can lead to poor surface finishes, dimensional inaccuracies, and increased tool wear. These vibrations occur when cutting forces and machine instability resonate at certain frequencies, disrupting the machining process.

Q: What causes chatter?

A: Chatter is primarily caused by an unstable interaction between the cutting tool, workpiece, and machine tool system. Insufficient machine rigidity, incorrect cutting parameters, tool wear, and material properties all contribute to chatter.

Q: What is mechanical chatter?

A: Mechanical chatter refers to vibrations within the machine tool system during machining, disrupting the cutting action. These vibrations are often caused by the resonance between the cutting forces, the machine’s natural frequency, and its structural rigidity.

Conclusion

Chatter in machining is a common problem that can affect part quality, productivity, and profitability. By understanding the root causes—such as machine-tool resonance, cutting forces, and rigidity—manufacturers can take targeted actions to minimize its impact. From optimizing cutting parameters to improving machine rigidity and using advanced tooling, there are many ways to combat chatter and achieve better machining outcomes.

In my experience, solving chatter issues not only improves productivity, but also improves product quality and results in significant cost savings. Through a combination of correctly applied technology, process adjustments and expertise, we can eliminate chatter and make machining operations more competitive.