Introduction

Casting is one of the oldest and most versatile manufacturing processes in the world. In simple terms, casting involves pouring molten material into a mold and letting it solidify to create a desired shape. This process has been used for centuries, dating back to ancient civilizations, and remains a cornerstone of modern manufacturing.

The origins of casting can be traced to ancient Egypt and Mesopotamia, where artisans cast bronze tools and statues. Over the centuries, casting techniques have evolved, becoming more precise and efficient, enabling the production of everything from intricate jewelry to massive engine blocks.

In today's manufacturing landscape, casting stands out for its ability to produce complex shapes, its cost-effectiveness for large-scale production, and its adaptability to various materials. In this guide, we will explore the casting process, its types, materials, advantages, challenges, and its role in shaping industries.

The Casting Process: A Step-by-Step Breakdown

Casting is a complex yet highly versatile manufacturing process that transforms raw materials into precise components. Below is a detailed and authoritative explanation of each step involved in the casting process.

Patternmaking

The first step in the casting process is patternmaking, where a replica of the desired part is created. This replica, called a pattern, serves as the blueprint for the mold.

-

Purpose:

The pattern defines the external shape of the casting and includes allowances for shrinkage, machining, and other factors that might affect the final product. -

Materials Used for Patterns:

- Wood: Lightweight, easy to shape, but prone to wear. Ideal for small production runs.

- Metal: Durable and precise, used for high-volume production. Common metals include aluminum and steel.

- Plastic: Combines lightweight and durability, suitable for medium-scale production.

-

Types of Patterns:

- Solid Patterns: A single-piece replica used for simple shapes.

- Split Patterns: Divided into two or more sections, enabling the creation of complex designs.

- Match-Plate Patterns: Mounted on a plate to ensure proper alignment during mold making, improving efficiency.

- Cope and Drag Patterns: Split into two halves (cope and drag) to create the upper and lower sections of the mold cavity.

-

Significance:

The accuracy of the pattern directly impacts the precision of the final casting. Patterns often undergo thorough inspection and testing before proceeding to the next step.

Mold Making

The mold is the critical component that forms the cavity into which molten material is poured. It must withstand extreme heat and pressure while maintaining dimensional accuracy.

-

Purpose:

To create a cavity that mirrors the desired part, ensuring the flow and cooling of molten material occur as planned. -

Mold Materials:

- Sand: Widely used for its versatility and low cost, ideal for expendable molds.

- Metal: Used for permanent molds, offering excellent durability and reusability.

- Ceramic: High heat resistance, often used for investment casting molds.

-

Types of Molds:

- Expendable Molds: Destroyed after each use. Commonly made from sand or plaster and used in processes like sand casting.

- Permanent Molds: Reusable and made from metal. Best for high-volume production with consistent dimensions.

-

Steps in Mold Making:

- Preparing the pattern and mold material.

- Compacting or pouring the mold material around the pattern.

- Removing the pattern to reveal the mold cavity.

-

Key Considerations:

Proper mold design minimizes defects like shrinkage and ensures uniform cooling of the molten material.

Melting

In this stage, the chosen material is heated to its melting point in specialized furnaces.

-

Purpose:

To achieve a liquid state for the material, ensuring it flows uniformly into the mold cavity. -

Types of Furnaces:

- Crucible Furnaces: Suitable for small-scale operations and non-ferrous metals.

- Electric Arc Furnaces: Used for high-temperature melting, particularly for steel and other ferrous metals.

- Induction Furnaces: Energy-efficient and precise, allowing accurate temperature control.

-

Critical Aspects:

- Temperature Control: Overheating can degrade material properties, while underheating may cause incomplete filling.

- Melt Quality: Impurities like slag must be removed to avoid defects in the final casting.

-

Safety Measures:

Melting involves high heat and potential hazards, requiring the use of protective equipment and adherence to strict safety protocols.

Pouring

Once the material reaches the desired temperature, it is poured into the mold cavity.

-

Purpose:

To transfer the molten material into the mold efficiently and uniformly without introducing defects. -

Pouring Techniques:

- Gravity Pouring: Relies on natural gravity to fill the mold. Suitable for simple and large parts.

- Pressure Pouring: Uses external pressure to improve flow into intricate molds.

- Vacuum Pouring: Reduces air entrapment, ideal for high-quality castings.

-

Key Considerations:

- Pouring Rate: Too fast can cause turbulence and defects; too slow may lead to incomplete filling.

- Temperature: The material must remain within an optimal range to ensure proper flow and solidification.

-

Special Equipment:

Ladles and pouring machines are often used to control the flow and maintain safety.

Solidification

The molten material begins to cool and solidify, forming the final shape of the casting.

-

Purpose:

To transition the liquid material into a solid state while retaining the mold's shape. -

Factors Affecting Solidification:

- Material Properties: Different metals and alloys have unique cooling rates and shrinkage behaviors.

- Mold Material: Highly conductive molds (e.g., metal) cool faster than less conductive ones (e.g., sand).

- Cooling Rate: Faster cooling often results in finer grain structures and improved strength.

-

Shrinkage Compensation:

Designers account for material shrinkage by adding allowances in the mold design. This ensures the casting meets dimensional requirements. -

Solidification Time:

Controlled by cooling channels or external cooling systems to achieve uniform cooling.

Removal (Shakeout)

Once the material has fully solidified, the casting is removed from the mold.

-

Purpose:

To extract the casting without damaging its structure or the mold (if reusable). -

Methods:

- Manual Removal: Suitable for small, simple castings.

- Mechanical Removal: Vibrating tables or shakers are used for larger or more complex molds.

-

Post-Removal Operations:

- Cleaning: Removal of sand, slag, or excess material from the casting.

- Trimming: Cutting off excess material like risers and gates.

- Surface Finishing: Processes like grinding, polishing, or machining are performed to meet dimensional and aesthetic requirements.

-

Inspection:

Each casting undergoes quality control to check for defects such as porosity, cracks, or dimensional inaccuracies.

Types of Casting Processes

Casting is a diverse manufacturing method with various techniques tailored to different applications, materials, and production requirements. Below is a detailed explanation of the most common casting processes, highlighting their mechanisms, advantages, disadvantages, and applications.

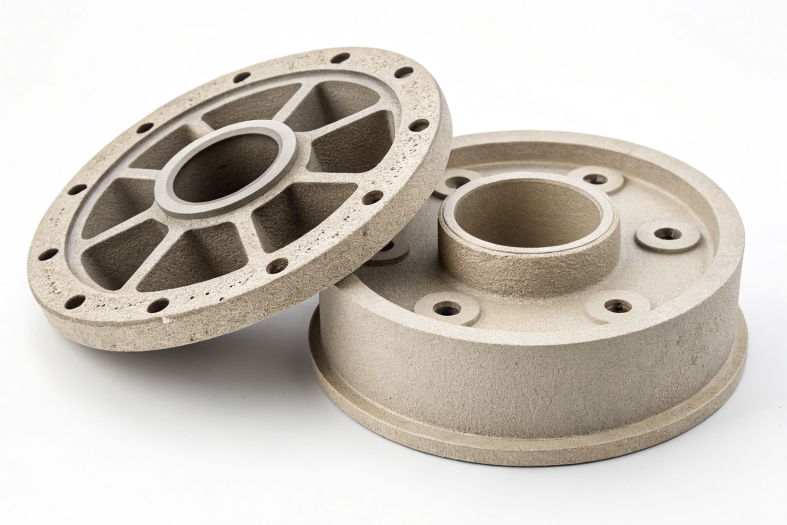

Sand Casting

Sand casting is one of the oldest and most widely used casting techniques. It is valued for its simplicity, adaptability, and cost-effectiveness.

-

Process:

Sand casting involves packing sand around a pattern to create a mold. The pattern is removed, leaving a cavity. Molten material is poured into this cavity, and after cooling, the sand mold is broken to retrieve the casting. -

Key Steps:

- Create a pattern that replicates the desired part.

- Pack sand around the pattern in a mold box.

- Remove the pattern to leave a cavity.

- Pour molten material into the cavity.

- Allow the material to cool and solidify.

- Break the sand mold to remove the casting.

-

Advantages:

- Low production cost due to reusable sand.

- Suitable for producing large and heavy parts.

- Can accommodate a wide range of metals.

-

Disadvantages:

- Rough surface finish requiring additional machining.

- Lower dimensional accuracy compared to other methods.

-

Applications:

- Engine blocks and heads in the automotive industry.

- Industrial parts such as pumps and valves.

- Construction components like pipes and fittings.

Investment Casting (Lost-Wax Casting)

Investment casting, also known as lost-wax casting, is a precision casting process used for creating intricate and high-quality components.

-

Process:

A wax pattern of the desired part is created, coated with ceramic material, and hardened. The wax is melted out, leaving a ceramic mold, which is then filled with molten material. Once the material solidifies, the ceramic mold is broken to release the casting. -

Key Steps:

- Create a wax model of the part.

- Dip the wax model in ceramic slurry and allow it to harden.

- Melt the wax to leave a hollow ceramic shell.

- Pour molten metal into the ceramic shell.

- Break the ceramic mold to retrieve the casting.

-

Advantages:

- Exceptional precision and surface finish.

- Capable of producing highly complex shapes.

- Can use a variety of alloys, including superalloys.

-

Disadvantages:

- Higher cost compared to sand casting.

- Longer process due to mold preparation.

-

Applications:

- Aerospace turbine blades.

- High-quality jewelry pieces.

- Medical implants and surgical tools.

Die Casting

Die casting is a high-pressure casting process used for producing large volumes of precise, uniform parts.

-

Process:

Molten metal is injected into a steel mold (die) under high pressure. The material solidifies quickly, and the casting is ejected. This process is often automated for high efficiency. -

Key Steps:

- Prepare the steel die.

- Heat the metal to its molten state.

- Inject molten metal into the die under high pressure.

- Cool the material to solidify.

- Eject the casting from the die.

-

Advantages:

- High production rates for mass manufacturing.

- Excellent surface finish and dimensional accuracy.

- Minimal post-processing required.

-

Disadvantages:

- Limited to non-ferrous metals like aluminum, zinc, and magnesium.

- High initial tooling costs.

-

Applications:

- Automotive components such as engine housings and transmission cases.

- Consumer electronics like camera bodies and laptop frames.

- Small appliances and industrial tools.

Permanent Mold Casting

Permanent mold casting uses reusable molds made from durable materials such as steel or cast iron.

-

Process:

A metal mold is preheated and coated to prevent sticking. Molten material is poured into the mold cavity, and after solidification, the casting is removed. The mold can be reused for multiple production cycles. -

Key Steps:

- Prepare and preheat the metal mold.

- Pour molten material into the mold cavity.

- Allow the material to cool and solidify.

- Open the mold to retrieve the casting.

-

Advantages:

- High repeatability for consistent production.

- Better surface finish compared to sand casting.

- Reduced waste and shorter production time.

-

Disadvantages:

- Limited to simpler shapes.

- Initial mold costs are higher than expendable molds.

-

Applications:

- Gears and rotors.

- Pipe fittings and flanges.

- Small automotive parts.

Centrifugal Casting

Centrifugal casting uses centrifugal force to distribute molten metal evenly within a rotating mold.

-

Process:

The mold is rotated at high speed while molten metal is poured into it. The centrifugal force pushes the material against the mold walls, creating a dense and uniform casting. -

Key Steps:

- Rotate the mold at high speed.

- Pour molten material into the rotating mold.

- Allow the material to solidify under centrifugal force.

- Remove the casting from the mold.

-

Advantages:

- Produces dense and defect-free parts.

- Excellent for cylindrical shapes.

- Minimal material waste.

-

Disadvantages:

- Limited to cylindrical parts.

- Requires specialized equipment.

-

Applications:

- Pipes and tubes.

- Bushings and bearings.

- Flywheels and rings.

Continuous Casting

Continuous casting is used for producing long, uniform shapes by continuously pouring molten material into a mold.

-

Process:

Molten metal is poured into a water-cooled mold, where it begins to solidify. The partially solidified material is continuously extracted and cut into desired lengths. -

Key Steps:

- Pour molten material into a water-cooled mold.

- Allow the material to begin solidifying.

- Extract the semi-solid material continuously.

- Cut the material into specified lengths.

-

Advantages:

- High efficiency for large-scale production.

- Uniform material properties.

- Suitable for mass production of standardized shapes.

-

Disadvantages:

- Limited to specific shapes like billets, slabs, and beams.

- Requires substantial setup and maintenance.

-

Applications:

- Steel billets and slabs.

- Aluminum ingots.

- Structural beams and rails.

Each casting process has unique characteristics, making it suitable for specific materials, shapes, and production volumes. Selecting the right process depends on the requirements of the final product and the production scale.

Materials Used in Casting

The choice of material in casting plays a critical role in determining the final product's properties, performance, and application. Below is a detailed and authoritative breakdown of the materials commonly used in casting.

Metals

Metals are the most widely used materials in casting due to their excellent mechanical properties and versatility. They can be broadly categorized into ferrous and non-ferrous metals.

Ferrous Metals

Ferrous metals contain iron as their primary component and are known for their strength and durability. They are widely used in industrial applications where high performance is essential.

-

Cast Iron:

- Types: Gray iron, ductile iron, white iron, and malleable iron.

- Characteristics: Excellent wear resistance, high compressive strength, and good machinability.

- Applications: Engine blocks, pipes, machine bases, and cookware.

- Advantages: Cost-effective, good fluidity for casting complex shapes.

- Disadvantages: Brittle nature, limited tensile strength compared to steel.

-

Steel:

- Types: Carbon steel, alloy steel, and stainless steel.

- Characteristics: High tensile strength, toughness, and corrosion resistance (in stainless steel).

- Applications: Structural components, gears, tools, and heavy machinery parts.

- Advantages: Versatility and strength, suitable for high-stress applications.

- Disadvantages: Higher melting point, requiring more energy and advanced equipment for casting.

Non-Ferrous Metals

Non-ferrous metals do not contain iron, making them lightweight and resistant to corrosion. They are ideal for applications where weight and environmental resistance are critical.

-

Aluminum:

- Characteristics: Lightweight, corrosion-resistant, excellent thermal and electrical conductivity.

- Applications: Automotive parts (engine housings, wheels), aerospace components, and consumer electronics.

- Advantages: Easy to cast, good surface finish, recyclable.

- Disadvantages: Lower strength compared to some ferrous metals.

-

Copper:

- Characteristics: Excellent thermal and electrical conductivity, corrosion-resistant.

- Applications: Electrical components, plumbing fittings, and decorative items.

- Advantages: High conductivity, antimicrobial properties.

- Disadvantages: Expensive, lower strength compared to steel.

-

Zinc:

- Characteristics: Low melting point, excellent corrosion resistance, and good fluidity.

- Applications: Die-cast components, hardware, and decorative items.

- Advantages: Cost-effective, ideal for small, intricate parts.

- Disadvantages: Limited use in high-temperature applications.

-

Magnesium:

- Characteristics: Extremely lightweight, high strength-to-weight ratio, good machinability.

- Applications: Aerospace and automotive components, electronics casings.

- Advantages: Ideal for weight-sensitive applications, good corrosion resistance with proper alloys.

- Disadvantages: Flammable in fine particle form, requires careful handling.

Other Materials

In addition to metals, other materials are used in casting for specialized applications, offering unique properties that metals cannot provide.

Plastics

Plastics are increasingly used in casting due to their lightweight nature and design flexibility. They are particularly suited for applications requiring complex shapes or insulation properties.

- Characteristics: Lightweight, corrosion-resistant, and non-conductive.

- Applications: Consumer goods, automotive interiors, and medical devices.

- Advantages: Low cost, excellent design flexibility, and reduced production energy requirements.

- Disadvantages: Limited strength and temperature resistance compared to metals.

Ceramics

Ceramics are ideal for high-temperature applications and environments requiring chemical resistance. They are used in both molds (investment casting) and as final casting materials.

- Characteristics: High heat resistance, excellent hardness, and chemical stability.

- Applications: Aerospace components (turbine blades), medical implants, and refractory linings.

- Advantages: Withstand extreme temperatures and harsh chemical environments.

- Disadvantages: Brittle nature, challenging to process compared to metals.

Factors Influencing Material Selection

The choice of material for casting depends on several factors, including:

- Application Requirements: Strength, weight, corrosion resistance, and conductivity.

- Casting Process: Different processes (e.g., sand casting, die casting) have specific material compatibility.

- Cost: Budget constraints influence the choice between ferrous and non-ferrous metals or other materials.

- Environmental Considerations: Recyclability and sustainability often play a role in material selection.

Advantages and Disadvantages of Casting

Casting is a highly versatile manufacturing process with numerous benefits, but it also comes with some limitations. Below is a detailed and authoritative explanation of the advantages and disadvantages of casting.

Advantages

1. Ability to Create Complex Shapes

Casting allows for the production of intricate and complex shapes that would be difficult or impossible to achieve with other manufacturing methods.

- Why It Matters:

- Casting enables the creation of internal cavities, intricate contours, and thin walls.

- It is particularly useful for components such as engine blocks, turbine housings, and jewelry.

- Example:

Investment casting can produce highly detailed turbine blades with precision cooling channels, essential for aerospace applications.

2. Cost-Effective for High-Volume Production

Casting becomes highly economical when producing large quantities of parts.

- Why It Matters:

- The initial tooling costs for molds and patterns can be high, but these costs are amortized over large production runs.

- Processes like die casting are automated, reducing labor costs and improving production efficiency.

- Example:

Die casting is extensively used in the automotive industry for high-volume production of transmission housings and engine components.

3. Wide Range of Materials Available

Casting is compatible with an extensive array of materials, from metals and alloys to plastics and ceramics.

- Why It Matters:

- It offers flexibility to meet diverse application requirements, such as strength, corrosion resistance, and thermal conductivity.

- Example:

Aluminum is used for lightweight automotive parts, while ceramics are employed for high-temperature turbine components.

4. Scalability for Large Components

Casting processes like sand casting can accommodate the production of very large components.

- Why It Matters:

- The ability to produce parts weighing several tons is critical for industries like construction, shipbuilding, and power generation.

- Example:

Large cast iron parts such as wind turbine bases or industrial machinery housings are produced using sand casting.

5. Minimal Material Wastage

Casting processes often result in minimal material wastage compared to machining or other subtractive manufacturing methods.

- Why It Matters:

- Excess material (e.g., gating and risers) can often be recycled, making casting a more sustainable choice.

Disadvantages

1. Potential Defects

Casting is prone to defects that can compromise the quality and performance of the final product.

- Common Defects:

- Porosity: Small voids caused by trapped air or gases during solidification.

- Shrinkage: Dimensional inaccuracies due to material contraction as it cools.

- Cold Shuts: Incomplete fusion of molten material, leading to weak spots.

- Mitigation:

- Proper mold design, controlled pouring rates, and advanced inspection techniques can minimize defects.

- Example:

Porosity in a turbine blade casting can reduce its strength and lead to failure under high stress.

2. Dimensional Accuracy Can Vary

Certain casting processes, such as sand casting, may have lower dimensional accuracy compared to machining or additive manufacturing.

- Why It Matters:

- Inconsistent dimensions require additional finishing operations, increasing costs and lead times.

- Example:

A sand-cast pump housing may need extensive machining to achieve the desired tolerances for seals and flanges.

3. Environmental Impact

Casting processes can have significant environmental consequences, including:

- Energy Consumption: High temperatures are required to melt materials, resulting in substantial energy use.

- Waste Generation: Sand casting, for example, generates large quantities of used sand that must be disposed of or recycled.

- Emissions: Foundries often produce emissions of gases and particulates that require careful management.

- Example:

Steel casting foundries are major consumers of energy and often face strict regulations on emissions and waste disposal.

4. High Initial Costs for Tooling

Processes like die casting and investment casting involve significant upfront costs for molds and patterns.

- Why It Matters:

- While cost-effective for high-volume production, the initial investment may not be justified for small runs.

- Example:

A custom aluminum die-cast mold for a low-volume product may result in a high per-unit cost.

5. Limited Suitability for Certain Applications

Casting may not be ideal for all manufacturing needs, especially where extreme precision or specialized materials are required.

- Why It Matters:

- Some components, such as those requiring ultra-high-strength or exotic materials, may be better suited for forging or additive manufacturing.

Balancing the Pros and Cons

Casting is a powerful manufacturing technique that balances complexity, material flexibility, and scalability with its inherent challenges. Modern advancements, such as automation, 3D printing for mold creation, and improved quality control, are continuously addressing these drawbacks, making casting more efficient and sustainable.

Understanding both the advantages and disadvantages allows manufacturers to choose the most suitable process for their specific needs, ensuring optimal performance and cost-efficiency.

Applications of Casting

Casting is an integral manufacturing process used across diverse industries due to its ability to produce components with complex geometries, a wide range of materials, and cost-effective scalability. Below is a detailed and authoritative explanation of casting applications in key sectors.

Automotive Industry

The automotive industry relies heavily on casting to produce critical components that require strength, durability, and precision.

-

Applications:

- Engine Blocks: Cast iron or aluminum engine blocks are made using sand or die casting processes. These blocks require high dimensional accuracy and excellent thermal properties.

- Cylinder Heads: Investment or die casting is used to produce lightweight, high-performance cylinder heads for combustion engines.

- Transmission Housings: Aluminum and magnesium housings are die-cast for their lightweight properties and excellent corrosion resistance.

-

Why Casting is Essential:

Casting allows for the integration of complex internal passages, such as cooling and oil flow channels, reducing the need for additional machining and assembly. -

Example:

Automotive manufacturers like Toyota and General Motors use aluminum die casting to produce lightweight yet durable engine components, contributing to improved fuel efficiency.

Aerospace Industry

The aerospace industry requires precision-engineered components that can withstand extreme temperatures and stresses.

-

Applications:

- Turbine Blades: Investment casting is the preferred method for creating intricate turbine blades with cooling channels. These blades are made from superalloys capable of withstanding high temperatures and pressures.

- Structural Components: Lightweight and high-strength aluminum or titanium components are sand or investment cast for aircraft frames and landing gear.

-

Why Casting is Essential:

The ability to produce complex geometries with excellent material properties ensures the reliability and efficiency of aerospace systems. -

Example:

Rolls-Royce uses precision investment casting to manufacture single-crystal turbine blades for jet engines, enhancing their performance and longevity.

Construction Industry

Casting plays a pivotal role in the construction industry, producing robust and durable components for infrastructure and building projects.

-

Applications:

- Pipes and Fittings: Cast iron and ductile iron pipes are produced using sand casting for water supply and sewage systems due to their strength and corrosion resistance.

- Structural Supports: Large steel or iron castings are used for beams, columns, and bridges, providing structural integrity.

-

Why Casting is Essential:

Casting enables the production of large and heavy parts required in construction projects, ensuring cost efficiency and scalability. -

Example:

The cast iron pipes used in urban drainage systems offer durability and a long service life, minimizing maintenance costs.

Manufacturing Industry

The manufacturing industry utilizes casting to create durable, high-performance components for machinery and tools.

-

Applications:

- Machine Tools: Cast iron bases for lathes, milling machines, and CNC machines are produced through sand casting, ensuring rigidity and vibration dampening.

- Industrial Equipment: Components like pump housings, valves, and gearboxes are cast for their precision and reliability.

-

Why Casting is Essential:

Casting offers flexibility in producing both small precision parts and large, robust machinery components. -

Example:

Heavy industrial equipment manufacturers like Caterpillar use sand casting to produce robust machine housings capable of withstanding harsh operating conditions.

Art and Jewelry

Casting is a vital process in the art and jewelry industries, enabling the creation of intricate and aesthetically pleasing designs.

-

Applications:

- Sculptures: Artists use lost-wax casting to produce detailed bronze or metal sculptures.

- Custom Jewelry: Investment casting is used to craft intricate rings, necklaces, and other jewelry pieces from precious metals like gold and silver.

-

Why Casting is Essential:

The precision and versatility of casting allow for creative freedom and high-quality finishes, essential for artistic and decorative applications. -

Example:

Jewelry designers like Tiffany & Co. use investment casting to create detailed and high-value custom pieces that meet exacting standards of quality and craftsmanship.

Future Trends in Casting

The casting industry is continuously evolving, driven by technological advancements and the demand for more efficient, precise, and sustainable manufacturing processes. Below is a detailed exploration of key future trends shaping the casting landscape.

Automation and Robotics

Automation and robotics are revolutionizing the casting industry by improving efficiency, consistency, and safety in production processes.

-

What It Involves:

Robotic systems and automated machinery are increasingly being deployed in tasks such as mold preparation, pouring molten metal, and finishing operations. These systems can work tirelessly, maintaining consistent quality and reducing human error. -

Benefits:

- Enhanced Productivity: Automation speeds up production cycles, allowing foundries to meet high-volume demands.

- Improved Safety: Robots handle hazardous tasks, such as pouring molten metal, reducing the risk of workplace injuries.

- Consistency: Robotic precision ensures uniform quality in each casting, minimizing defects.

-

Examples:

Foundries equipped with robotic arms for pouring and shakeout processes can produce thousands of castings with consistent quality. Companies like ABB and FANUC are leading the development of robotics tailored to the casting industry.

Additive Manufacturing

Additive manufacturing (3D printing) is increasingly being integrated into casting, particularly in the creation of molds and patterns.

-

What It Involves:

3D printing is used to create complex and precise molds or patterns directly from digital designs, bypassing traditional tooling methods. -

Benefits:

- Design Freedom: Enables the production of intricate geometries that were previously unachievable with traditional methods.

- Faster Prototyping: Reduces the lead time for developing new molds or patterns, accelerating product development cycles.

- Cost Efficiency: Eliminates the need for expensive tooling in low-volume or custom production.

-

Examples:

Aerospace manufacturers are leveraging 3D-printed molds to produce turbine blades with complex internal cooling channels, enhancing efficiency and performance.

Process Control

Advanced sensors and real-time monitoring systems are transforming casting processes, enabling greater control and precision.

-

What It Involves:

Sensors embedded in molds and furnaces provide real-time data on temperature, pressure, and material flow during the casting process. -

Benefits:

- Defect Prevention: Continuous monitoring allows for early detection of anomalies, reducing the likelihood of defects like porosity or shrinkage.

- Improved Quality: Data analytics optimize process parameters, ensuring consistent and high-quality outputs.

- Operational Efficiency: Real-time feedback reduces waste and rework, saving time and resources.

-

Examples:

Smart foundries are adopting IoT (Internet of Things) technologies to track and optimize casting processes, ensuring precise control over every stage of production.

Sustainable Practices

Sustainability is becoming a cornerstone of modern casting, with efforts focused on reducing waste, energy consumption, and environmental impact.

-

What It Involves:

Foundries are adopting energy-efficient furnaces, recycling materials, and implementing waste reduction techniques to minimize their carbon footprint. -

Benefits:

- Energy Efficiency: Advanced furnaces, such as electric arc and induction types, consume less energy and produce fewer emissions.

- Material Recycling: Reusing sand, scrap metal, and by-products reduces waste and lowers production costs.

- Regulatory Compliance: Meeting stricter environmental regulations ensures the longevity of operations and corporate responsibility.

-

Examples:

Companies like Tesla have adopted sustainable casting methods in their Giga Casting process, using recyclable aluminum alloys to manufacture large vehicle components with minimal waste.

Conclusion

Casting is a foundational manufacturing process with a rich history and broad industrial applications. Its ability to produce complex shapes and use diverse materials makes it invaluable across industries like automotive, aerospace, and construction. As technologies like automation and 3D printing continue to evolve, casting remains an essential process shaping the future of manufacturing.

For those interested in learning more, explore casting innovations, study detailed case studies, or visit manufacturing facilities to witness this fascinating process in action.

FAQ on Casting

What is the meaning of casting?

Casting is a manufacturing process in which molten material, typically metal, is poured into a mold with a hollow cavity of the desired shape. Once the material cools and solidifies, it is removed from the mold, forming the final product.

What is the difference between molding and casting?

- Molding refers to creating the mold itself, which is the hollow cavity used to shape the material.

- Casting involves pouring molten material into the mold and letting it solidify to form the desired part.

In short, molding is about making the mold, while casting uses the mold to produce the part.

What is meant by casting process?

The casting process is a step-by-step manufacturing method that includes:

- Patternmaking: Creating a replica of the desired part.

- Mold Making: Forming a cavity to hold molten material.

- Melting: Heating material to its liquid state.

- Pouring: Filling the mold with molten material.

- Solidification: Allowing the material to cool and harden.

- Removal: Extracting the finished product from the mold.

The process is used for producing parts with complex shapes in various materials.

What are types of casting?

The main types of casting include:

- Sand Casting: Uses sand molds; suitable for large, complex parts.

- Die Casting: Injects molten metal into a metal die under high pressure; ideal for high-volume production.

- Investment Casting: Creates precise parts with a wax pattern and ceramic mold.

- Permanent Mold Casting: Uses reusable metal molds for consistent production.

- Centrifugal Casting: Spins the mold to distribute molten metal evenly, great for cylindrical shapes.

- Continuous Casting: Produces long, uniform shapes like billets and slabs.

Each method is chosen based on the material, complexity, and production volume required.