The efficient operation of CNC machines relies on the coordinated functioning of various components. However, many people lack a thorough understanding of these components and their roles. This knowledge gap can lead to reduced machining accuracy, inefficiencies, and higher maintenance costs. A clear understanding of these core parts helps optimize machine performance and minimize downtime.

Direct Answer:

Key CNC machine components include the controller, drive system, spindle, machine tool, cutting tools, feedback system, coolant system, lubrication system, and auxiliary devices like tool changers, chip management systems, and safety enclosures.

Controller

The CNC controller is the central processing unit of the machine, tasked with interpreting G-code and managing operations. Key functions include:

- Interpolation: Calculates intermediate points for smooth axis movements, ensuring high accuracy in contouring.

- Data Processing: Converts CAD/CAM data into machine-readable formats, often enhancing speed with parallel processing capabilities.

- Multi-Axis Control: Synchronizes movements in up to five or more axes simultaneously for complex geometries, such as in aerospace and medical components.

- Error Detection and Compensation: Monitors discrepancies such as thermal expansion and dynamically adjusts machining parameters.

Modern controllers integrate edge computing and real-time analytics, enabling predictive maintenance and optimizing machine throughput.

Actuators

Actuators are responsible for precise mechanical movement, driven by electrical signals from the controller. Key types include:

- Stepper Motors:

- Operate in discrete steps, offering positional accuracy within 0.01mm.

- Commonly used in less dynamic applications such as prototyping or light-duty machining.

- Servo Motors:

- Incorporate closed-loop feedback for deviation correction, enabling real-time adjustments.

- Ideal for high-speed and high-torque applications, achieving acceleration rates of 10 m/s² or more.

Emerging technologies include piezoelectric actuators, offering nanometer-level positioning accuracy for ultra-precise applications.

Machine Tool

The machine tool determines the machining capabilities of a CNC system. Examples include:

- Vertical Milling Machines: Suited for dies, molds, and high-precision flat surfaces.

- CNC Lathes: Specialized for rotational symmetry, including parts like turbine blades and shafts.

- Grinding Machines: Ensure superior surface finishes, achieving tolerances as tight as ±0.0001mm in high-end setups.

Recent innovations in hybrid CNC machines combine additive and subtractive manufacturing, expanding machining possibilities.

Cutting Tools

Cutting tools are critical for shaping materials. Selection depends on hardness, thermal conductivity, and surface finish requirements. Examples include:

- End Mills: With variable flute geometries for chatter reduction.

- Polycrystalline Diamond (PCD) Tools: Exceptional for non-ferrous materials and composites.

- Reamers and Boring Bars: Ensure ultra-precise internal diameters.

Emerging materials like cubic boron nitride (CBN) are expanding machining capabilities for hardened steels and alloys.

Spindle

The spindle is the core of cutting operations. Specifications include:

- Speed and Torque Range: Advanced spindles can switch dynamically between high-speed (up to 120,000 RPM) and high-torque modes.

- Cooling Mechanisms: Incorporating oil-mist or liquid-cooled designs for consistent thermal control.

- Adaptive Tool Holders: Systems like shrink-fit or hydraulic holders enhance tool concentricity and reduce vibration.

Intelligent spindles now monitor their own vibrations and thermal states, adjusting dynamically to ensure consistent machining quality.

Drive System

The drive system governs axis movement. Key advancements include:

- Direct Drive Motors: Eliminate transmission components for ultra-fast response and acceleration.

- Ball Screws with Anti-Backlash Mechanisms: Provide positioning precision below ±0.005mm.

- Magnetic Linear Drives: Offering frictionless operation, increasing speed and longevity.

Advanced systems integrate smart damping technologies to minimize chatter during aggressive cuts.

Feedback System

Feedback systems are integral for precision. Key technologies include:

- Encoders and Linear Scales: Ensure accuracy within ±0.0005mm in demanding aerospace applications.

- Vision Systems: Monitor and correct machining errors in real time using AI-enhanced image processing.

- Acoustic Emission Sensors: Detect tool wear and impending breakage.

These technologies are critical in achieving nanometer-level tolerances in microfabrication industries.

Coolant System

Efficient cooling extends tool life and enhances surface finish. Types include:

- MQL (Minimum Quantity Lubrication): Reduces environmental impact while providing effective lubrication.

- High-Pressure Coolants (HPC): Essential for deep-hole drilling and hard-turning operations.

- Eco-Friendly Synthetic Coolants: Designed for sustainable manufacturing practices.

Emerging cryogenic cooling methods are proving vital for machining heat-sensitive materials like titanium.

Lubrication System

Proper lubrication reduces wear and ensures smooth machine operation. Advanced types include:

- Active Lubrication Systems: Monitor and dispense lubrication dynamically based on load and speed.

- Graphite-Based Solid Lubricants: Used in extreme environments where liquid lubrication is infeasible.

Auxiliary Components

Auxiliary systems enhance efficiency and safety. Key developments include:

- Advanced Chip Management Systems: Vacuum-assisted systems for rapid chip removal.

- Automated Tool Changers (ATC): Configurations handling up to 400 tools for uninterrupted operation.

- Augmented Safety Enclosures: Featuring real-time monitoring of environmental conditions like noise and temperature.

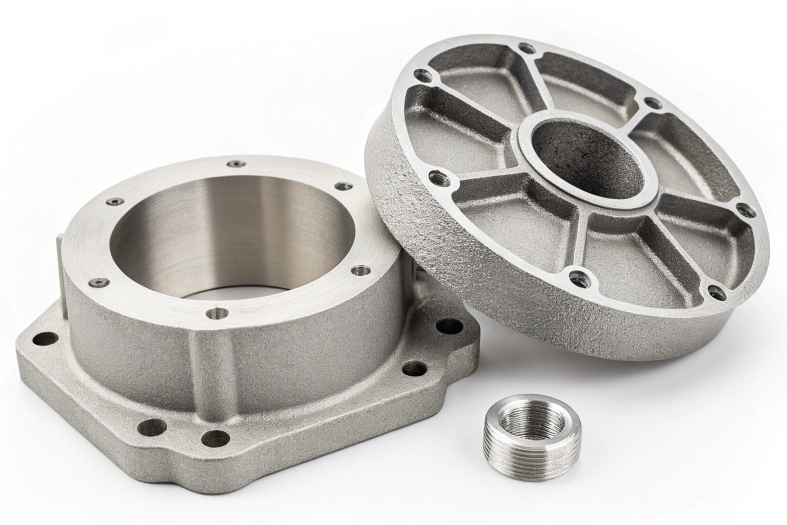

Materials Used for CNC Components

Materials are chosen based on application requirements:

- Titanium Alloys: Preferred for lightweight, high-strength moving parts.

- Advanced Ceramics: Provide superior wear resistance and thermal stability in high-speed spindles.

- Carbon Fiber Composites: Reduce weight in dynamic assemblies, enhancing acceleration.

Conclusion

CNC machines are more than just mechanical marvels; they are the unsung heroes of modern manufacturing. Each precisely milled surface, every intricate cut, and every flawless component is the culmination of countless hours of engineering brilliance and hands-on expertise. These machines, though built of metal and wires, are deeply connected to the creativity and skill of their operators.

Understanding the roles and interactions of CNC components goes beyond technical knowledge—it’s about unlocking the true potential of what these machines can achieve. It’s the difference between a part that’s merely functional and one that’s a masterpiece of precision and efficiency. Every controller command, spindle rotation, and tool path reflects the dedication of those striving to push the boundaries of what’s possible.

As technological advancements continue to evolve, from AI-optimized controllers to hybrid machining systems, the future of CNC machining holds endless possibilities. These innovations aren’t just tools—they’re enablers of dreams, empowering us to create everything from life-saving medical devices to components destined to shine in their fields.

In the end, a CNC machine isn’t just a piece of equipment; it’s a collaborator in creation. It’s the bridge between imagination and reality, transforming raw materials into works of art. Whether you’re a seasoned machinist or new to the craft, embracing the intricacies of CNC technology isn’t just an investment in machinery—it’s an investment in innovation, precision, and progress.