In the world of CNC machining, understanding the terminology is crucial for both professionals and newcomers alike. The complexity of the technology can make it difficult to keep up with the myriad of terms used daily. Whether you're an operator, a designer, or just someone interested in the field, getting familiar with these terms will help you make informed decisions and communicate effectively within the industry. But how can you navigate through this sea of technical jargon without feeling overwhelmed?

Direct Answer:

Common CNC machining terms include CNC mills (machines for cutting and shaping materials), CNC lathes (machines for turning cylindrical parts), CNC EDM (Electrical Discharge Machines for precise cuts using sparks), and CNC plasma cutters (machines for cutting metals with plasma). Other key terms include G-code (programming language for machine control), M-code (controls machine functions), toolpath (the path the tool follows), feed rate (speed of tool movement), and spindle speed (rotation speed of the tool). These terms are essential for understanding and operating CNC machinery effectively.

Common CNC Machining Terms

CNC Machine Types

CNC Mill

A CNC mill is a type of machine that uses rotating cutters to remove material from a workpiece. The mill can perform a variety of machining operations, including drilling, boring, and shaping. CNC mills come in two primary configurations:

- Vertical Mills: The spindle axis is oriented vertically, and the workpiece is placed beneath the cutting tool. Vertical mills are often used for smaller, detailed parts or for drilling operations.

- Horizontal Mills: These mills use a horizontally oriented spindle, which makes them ideal for larger, heavier parts or high-precision operations requiring complex tool paths.

CNC mills can handle a variety of materials, including metals, plastics, and composites, making them incredibly versatile in industries such as aerospace, automotive, and medical device manufacturing.

CNC Lathe

CNC lathes are machines where the workpiece is rotated while a stationary cutting tool removes material. This process is known as turning. CNC lathes are widely used to produce cylindrical parts, such as shafts, tubes, and pulleys.

- CNC Turning Centers: These machines have more advanced capabilities, including the ability to handle both axial and radial movements. They are often equipped with live tooling to allow for drilling and milling operations in addition to turning.

CNC EDM (Electrical Discharge Machine)

CNC EDM uses electrical discharges (or sparks) to erode material from the workpiece. The process works by creating a series of rapid electrical discharges that wear away the material from the surface. This method is ideal for:

- Cutting hard materials such as tool steels, titanium, and carbide.

- Intricate and precise cuts, such as when producing complex geometric shapes or tight tolerances that would be impossible with traditional cutting methods.

EDM is commonly used in industries like aerospace, mold-making, and tool and die manufacturing.

CNC Plasma Cutter

CNC plasma cutters utilize a high-temperature plasma arc to cut through electrically conductive materials like steel, aluminum, and copper. The plasma jet melts the material, and the high-speed airflow blows the molten material away.

- This process is ideal for high-speed cutting of thick metal sheets.

- CNC plasma cutters are often used in heavy-duty industries such as construction, automotive manufacturing, and shipbuilding due to their efficiency and ability to handle large-scale cutting operations.

G-Code

G-Code is the most widely used programming language in CNC machining. It consists of a series of alphanumeric codes that control machine operations, such as tool movement, speed, and positioning. Common G-Codes include:

- G00: Rapid positioning

- G01: Linear interpolation (controlled cutting movement)

- G02/G03: Circular interpolation (clockwise/counter-clockwise motion)

- G21: Metric system (millimeters)

- G54: Work coordinate system (defines the origin of the part for machining)

Understanding G-Codes is fundamental to CNC programming and ensures the correct execution of machining operations.

M-Code

M-Code commands are used to control machine functions that are not related to tool movement. M-Codes typically control operations such as:

- M03: Spindle ON (clockwise rotation)

- M05: Spindle STOP

- M08: Coolant ON

- M09: Coolant OFF

- M06: Tool change

M-Codes are essential for controlling auxiliary machine functions and ensuring the proper sequencing of operations.

Toolpath

A toolpath refers to the precise path that the cutting tool follows during the machining process. Toolpaths are generated using CAM software, and they are influenced by factors such as:

- The geometry of the part

- The cutting tool’s shape and size

- The material of the workpiece

Accurate toolpath generation is critical to producing parts that meet specified dimensions and tolerances. In CNC machining, toolpath optimization can lead to faster cycle times and reduced wear on cutting tools.

Feed Rate

The feed rate is the speed at which the cutting tool moves relative to the workpiece during machining. It is typically measured in units such as millimeters per minute (mm/min) or inches per minute (ipm).

- High feed rates increase productivity but may reduce precision if not carefully controlled.

- Lower feed rates provide higher precision but can increase machining time.

Selecting the correct feed rate is vital for optimizing the machining process, ensuring that the part is produced within the desired tolerances and surface finish.

Spindle Speed

Spindle speed refers to the rotational speed of the CNC machine’s spindle, typically measured in revolutions per minute (RPM). The spindle speed determines the cutting conditions, and it varies depending on:

- The type of material being cut (harder materials generally require slower spindle speeds)

- The cutting tool being used (some tools perform best at higher speeds)

- The type of operation being performed (drilling may require different speeds than milling)

The spindle speed must be adjusted to achieve the optimal cutting conditions and tool life.

CAD (Computer-Aided Design)

CAD software is used to create detailed 2D or 3D models of parts and components. These digital models serve as the blueprint for CNC machining. CAD allows engineers and designers to visualize and modify the part before it enters the manufacturing phase, improving efficiency and reducing errors.

CAM (Computer-Aided Manufacturing)

CAM software translates the digital design files from CAD into machine-readable code (G-code) that directs the CNC machine. CAM optimizes the machining process by:

- Generating the toolpaths

- Calculating the correct feed rates and spindle speeds

- Providing detailed simulations to verify that the machining operation will proceed without issues

Using CAM software helps improve efficiency, reduce material waste, and ensure precise execution of the machining process.

CNC Workholding

Workholding refers to the methods and devices used to secure a workpiece on a CNC machine during machining. Secure workholding is essential for preventing parts from shifting during operations, ensuring accuracy and consistency. Common workholding devices include:

- Vices: Used for clamping the part in place.

- Chucks: Often used in lathes for holding cylindrical parts.

- Fixtures: Custom-built devices for securing complex parts during machining.

Tool Holder

A tool holder is the device that securely holds a cutting tool in place on the CNC machine. Tool holders must be robust enough to withstand the forces generated during machining while ensuring the tool remains precisely positioned throughout the process.

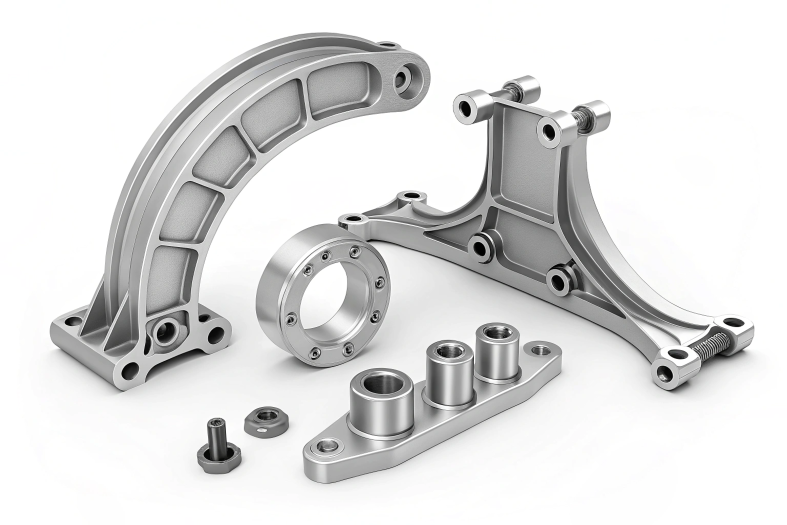

Cutting Tools

Cutting tools are the tools used by CNC machines to remove material from the workpiece. These tools vary depending on the material, operation, and desired finish. Common cutting tools include:

- End mills: Used for milling operations.

- Drills: Used for drilling holes.

- Taps: Used for cutting internal threads.

The choice of cutting tool is crucial to achieving the desired finish, precision, and tool life.

Clearance Plane

The clearance plane is the height above the workpiece that the cutting tool travels to when it needs to move between operations. Maintaining a clearance plane ensures the tool does not make accidental contact with the workpiece, avoiding potential damage or unwanted cuts.

CNC Control System

The CNC control system is the software and hardware responsible for interpreting G-code and M-code commands, controlling the movements of the tool and machine. This system manages the entire machining process, ensuring that the operations are executed according to the design specifications.

Common CNC Machining Processes

Milling

Milling involves using rotary cutters to remove material from a workpiece. The cutting tool moves along multiple axes, carving out the desired part geometry. Milling can be done on both vertical and horizontal CNC mills, with different configurations suited for different types of parts and operations. This process is highly versatile, capable of creating a wide range of features such as slots, pockets, and holes.

Turning

Turning is a machining process where the workpiece is rotated while a stationary cutting tool removes material. It is typically used to produce parts with cylindrical shapes, such as shafts, bushings, and bolts. Turning can also include additional operations, such as threading, boring, and facing.

Drilling

Drilling is the process of using a rotating drill bit to create round holes in a material. Drilling is often followed by tapping to create internal threads for screws or bolts. Drilling is a fundamental operation in CNC machining, commonly used for producing holes for fasteners, bearings, and other components.

Grinding

Grinding is an abrasive machining process where a rotating wheel is used to smooth or finish a part. It is often used to achieve fine surface finishes or tight tolerances. Grinding is commonly used on parts that require precise dimensions or a high-quality surface finish, such as in the aerospace or medical industries.

Electrical Discharge Machining (EDM)

EDM is a non-traditional machining process that uses electrical sparks to erode material from the workpiece. It is particularly effective for hard-to-machine materials and can be used for cutting intricate shapes that are difficult to achieve with conventional machining methods.

Laser Cutting

Laser cutting is a non-contact machining process that uses a focused laser beam to melt, burn, or vaporize material, leaving a clean edge. This process is particularly useful for cutting sheet metal, plastics, and other materials with high precision. CNC laser cutters are widely used for:

- High-precision cutting: Laser cutting provides exceptional accuracy, with tolerances as tight as ±0.1mm, making it ideal for intricate designs.

- Minimal thermal distortion: Since the heat is localized to a very small area, there is minimal heat-affected zone (HAZ), which is crucial when working with sensitive materials.

- Clean, smooth edges: Laser cutting often eliminates the need for additional finishing steps, resulting in high-quality edges and minimal burr formation.

Laser cutting is often used in industries such as automotive, aerospace, and electronics, particularly for prototyping and short-run production where precision and efficiency are critical.

Common CNC Machining Processes

Milling

Milling is one of the most versatile CNC machining processes, where rotary cutters are used to remove material from a workpiece. There are two main types of milling:

- Face Milling: The cutting tool is positioned perpendicular to the workpiece, and material is removed from the surface.

- Peripheral Milling: The cutting tool rotates parallel to the workpiece, and material is removed along the sides.

CNC milling machines can handle a wide range of materials, including metals (e.g., steel, aluminum), plastics, and composites. Milling is commonly used to create complex shapes, such as gears, housings, and multi-dimensional components.

Turning

Turning involves rotating the workpiece while a fixed cutting tool removes material. The process can be performed on CNC lathes, which are especially suited for producing:

- Cylindrical parts: Such as shafts, rods, and tubes.

- Conical parts: Like tapers and conical surfaces.

- Threads: Both internal and external threading are common turning applications.

CNC turning provides high precision, and parts can be manufactured quickly and with excellent surface finishes, making it ideal for high-volume production runs.

Drilling

Drilling is one of the most basic and widely used CNC machining operations. It involves the use of a rotating drill bit to create round holes in the material. Drilling operations can include:

- Simple drilling: Used to create straight, round holes.

- Deep hole drilling: Often used when precise, deep holes are required.

- Tapping: After drilling, tapping is often used to create internal threads for screws or bolts.

CNC drilling can be automated for high-speed operations and is used extensively in industries such as electronics, automotive, and manufacturing.

Grinding

Grinding is a machining process that uses an abrasive wheel to remove material from the workpiece, producing a smooth finish and achieving high precision. Grinding is often used when:

- Fine surface finish is required: For parts that need a polished or smooth surface.

- High precision is critical: For parts requiring tight tolerances and minimal deviation in dimensions.

Grinding is commonly used in the final stages of production for parts that require a superior surface finish or very precise geometric dimensions.

Electrical Discharge Machining (EDM)

EDM is a non-traditional machining process that uses electrical discharges (sparks) to erode material from a workpiece. This technique is ideal for:

- Hard materials: Such as tool steels, titanium, and carbide, which are difficult to machine using traditional cutting tools.

- Intricate shapes: EDM allows for the creation of complex, high-precision parts with geometries that may be impossible to achieve through conventional machining methods.

- No mechanical stress: Since there is no physical contact between the electrode and the workpiece, there’s no mechanical stress on the material.

EDM is commonly used for mold making, tool and die production, and aerospace components.

Conclusion

CNC machining involves a wide array of complex terms, processes, and technologies, each of which plays a critical role in ensuring precise and efficient manufacturing. By understanding the key terms and concepts discussed in this article, you’ll be better equipped to communicate with suppliers, optimize your machining processes, and select the appropriate technologies for your needs.

As the field of CNC machining continues to evolve, keeping up with these terms and processes will ensure you stay at the cutting edge of manufacturing. Whether you are designing parts, sourcing components, or executing high-precision machining operations, mastering these CNC concepts will significantly improve your workflow and lead to better outcomes.

FAQ:

What is the most common CNC language?

The most common language used in CNC machining is G-code. G-code is the programming language that directs CNC machines to perform specific tasks such as movement, cutting, and tool control. It provides machine operators with commands to execute precise operations on the workpiece.

What are the basics of CNC machining?

CNC machining is the process of using computer-controlled machines to cut, shape, or fabricate materials. The basic steps include:

- Designing the part using CAD (Computer-Aided Design) software.

- Generating the toolpath using CAM (Computer-Aided Manufacturing) software.

- Programming the CNC machine with G-code to execute the machining operations.

- Securing the material on the machine with workholding devices.

- Executing the machining operation, where tools remove material according to the programmed instructions.

What are the codes in a CNC machine?

In CNC machining, there are two main types of codes:

-

G-codes (Geometric codes): These control the movement of the machine, such as linear or circular motion. Common G-codes include:

- G00: Rapid positioning.

- G01: Linear interpolation (cutting).

- G02/G03: Circular interpolation (clockwise/counterclockwise).

-

M-codes (Miscellaneous codes): These control other machine functions, such as turning the spindle on/off, activating coolant, or changing tools. Examples of M-codes include:

- M03: Start spindle clockwise.

- M05: Stop spindle.

- M08: Turn on coolant.

What is the most widely used code?

The most widely used CNC code is G-code, specifically G01 (linear interpolation). This code instructs the machine to move the tool in a straight line from one point to another, making it fundamental in almost all CNC machining operations, from simple drilling to complex milling.