In the CNC machining industry, customer-provided drawings are critical for custom production. However, many companies face challenges in interpreting these drawings, such as format compatibility, differing annotation standards, or missing key details. If not handled properly, it can lead to production delays or non-compliant products. Therefore, mastering the correct way to review customer drawings is essential for ensuring efficiency and quality.

To accurately view and interpret drawings provided by customers:

- Start with the Title Block: Review the part name, drawing number, revision, scale, and material specifications to ensure you have the correct version of the drawing.

- Understand Dimensions and Tolerances: Carefully check all linear, angular, and geometric dimensions, including tolerances, as they directly impact manufacturability.

- Refer to Notes and Symbols: Read all notes for special instructions (e.g., surface finishes, heat treatments) and decode symbols using the legend.

- Check for Missing Information: Look for any gaps or unclear details in the drawing and address them promptly.

- Utilize CAD Software: Use tools like AutoCAD or NX to analyze 2D and 3D drawings for enhanced clarity.

- Clarify Ambiguities: Communicate with the customer to resolve uncertainties or confirm specifications.

By following these steps, you ensure precise manufacturing and strengthen customer trust through professional handling of their technical drawings.

Understanding Projection Methods: First Angle vs. Third Angle and Their Impact on Drawing Interpretation

Accurate interpretation of engineering drawings is crucial for successful manufacturing. A fundamental aspect of this process is understanding the projection method used: First Angle Projection or Third Angle Projection. These methods, governed by international standards (ISO/EN and ANSI), dictate how 3D objects are represented in 2D, directly influencing the layout of views on a drawing. Misinterpreting the projection can lead to costly errors, making a clear understanding essential.

First Angle vs. Third Angle Projection: A Detailed Comparison

The core difference lies in the placement of the projection plane relative to the observer and the object.

First Angle Projection (ISO/EN)

- Definition: In First Angle Projection, the object is placed between the observer and the projection plane. Imagine shining a light through the object onto a screen behind it; the resulting shadow is the projection.

- Visual Analogy: Think of the object as being "impaled" on the projection plane.

- View Arrangement:

- Top View: Positioned below the Front View.

- Left Side View: Positioned to the right of the Front View.

- Right Side View: Positioned to the left of the Front View.

- Symbol: A truncated cone symbol is used to indicate First Angle Projection.

- Geographic Prevalence: Primarily used in Europe, Asia, and other regions.

Third Angle Projection (ANSI)

- Definition: In Third Angle Projection, the projection plane is placed between the observer and the object. Imagine placing the object inside a transparent box; the views are projected onto the inside faces of the box.

- Visual Analogy: Think of the object as being "inside" a glass box, with the views projected onto the box's walls.

- View Arrangement:

- Top View: Positioned above the Front View.

- Left Side View: Positioned to the left of the Front View.

- Right Side View: Positioned to the right of the Front View.

- Symbol: A truncated cone symbol, different from the First Angle symbol, is used to indicate Third Angle Projection.

- Geographic Prevalence: Predominantly used in the United States, Canada, and other regions.

Tabular Comparison

| Feature | First Angle Projection (ISO/EN) | Third Angle Projection (ANSI) |

|---|---|---|

| Object Placement | Between observer and plane | Between plane and observer |

| Projection Analogy | Object "impaled" on plane | Object "inside" a glass box |

| Top View Position | Below Front View | Above Front View |

| Left View Position | Right of Front View | Left of Front View |

| Symbol | Truncated cone (specific shape) | Truncated cone (different shape) |

| Primary Usage | Europe, Asia | USA, Canada |

The Critical Importance of Correct Projection Interpretation

Misinterpreting the projection method can lead to disastrous consequences in manufacturing.

- Manufacturing Errors: Incorrect view orientation results in parts being manufactured incorrectly, leading to rework, scrap, and delays.

- Assembly Issues: When mating parts are manufactured based on different projection interpretations, they will not fit together correctly.

- Communication Breakdown: Confusion between engineers, manufacturers, and clients can arise, leading to miscommunication and project setbacks.

Drawing Types and Their Interpretation in the Context of Projection

Understanding projection is essential for interpreting different types of engineering drawings.

- 2D Orthographic Drawings: These rely heavily on projection methods to represent 3D objects in 2D. Correctly identifying the projection (First or Third Angle) is crucial for understanding the spatial relationships between the different views.

- 3D Models with 2D Drawings: Even when 3D models are available, 2D drawings are often still used for manufacturing details. The projection method remains relevant for interpreting these associated 2D drawings.

Avoiding Projection Interpretation Errors: Best Practices

- Identify the Projection Symbol: Always check the title block for the projection symbol. This is the most reliable way to determine the projection method used.

- Check for Explicit Notation: Some drawings explicitly state "First Angle Projection" or "Third Angle Projection" in the title block or notes.

- Adhere to Company Standards: If working within a company or organization, follow their established drawing standards and conventions.

- Communicate and Clarify: When in doubt, always communicate with the drawing's creator or the customer to clarify any ambiguities regarding the projection method.

- Use CAD Software Features: Modern CAD software often provides features to automatically orient views based on the selected projection standard.

By understanding the fundamental differences between First and Third Angle Projection and implementing these best practices, you can significantly reduce the risk of costly errors and ensure the successful execution of your projects.

Key Elements to Look for in a Drawing: A Detailed Examination

Title Block: The Drawing's Identity

The title block provides critical administrative and descriptive information about the part.

- Details:

- Part Name/Description: Identifies the component represented.

- Drawing Number: Unique identifier for tracking and referencing.

- Revision Level/History: Indicates the current version of the drawing and records changes. Ensures you work with the latest data.

- Scale: Ratio between drawing dimensions and actual part size (e.g., 1:1, 2:1).

- Material: Specifies the material(s) for manufacturing.

- Personnel: Includes "Drawn By," "Checked By," and "Approved By" details.

- Date: Indicates creation or revision date.

- Company Information: Features the logo and name of the responsible organization.

- Best Practice:

Always verify the revision number to ensure you are using the most up-to-date version of the drawing. Discrepancies between revisions can cause costly errors.

Dimensions and Tolerances: Defining Size and Acceptable Variation

Dimensions and tolerances specify the size, shape, and allowable variations for the part.

- Types:

- Linear Dimensions: Define distances and diameters.

- Angular Dimensions: Specify angles between surfaces or features.

- Geometric Dimensions and Tolerances (GD&T): Use symbols to define form, profile, orientation, and location tolerances. Essential for ensuring fit and function.

- Importance:

Tolerances establish acceptable variations critical for functionality and interchangeability. Proper interpretation aids in selecting the right manufacturing processes.

Notes and Specifications: Additional Instructions and Requirements

Notes and specifications convey additional requirements not detailed in dimensions and tolerances.

- Examples:

- Surface Finish Requirements: Specify roughness or smoothness levels.

- Heat Treatments: Detail hardening or annealing processes.

- Welding Instructions: Define weld types and sizes.

- Assembly Notes: Provide instructions for assembling parts.

- Special Manufacturing Processes: Highlight specific machining or finishing operations.

- Action:

Carefully review all notes. Missing a critical specification can result in non-conforming parts or rework.

Symbols and Legends: Standardized Communication

Symbols provide a concise and universal way to represent features and conditions.

- Common Symbols:

- GD&T Symbols: For geometric tolerances (e.g., flatness, perpendicularity).

- Welding Symbols: Indicate joint types and processes.

- Surface Finish Indicators: Define texture and roughness.

- Thread Symbols: Specify thread type and size.

- Best Practice:

Refer to the drawing's legend or standards like ASME Y14.5 for GD&T to understand unfamiliar symbols.

Datum and Coordinate Systems:

Datums and coordinate systems provide a framework for accurate machining and inspection.

- Purpose:

Datums are reference points, lines, or planes used to locate features accurately. Coordinate systems define the part's origin and orientation in space. - Implementation:

Align datum features with machine setups or inspection plans, ensuring consistent and repeatable results.

Step-by-Step Process for Viewing Customer Drawings:

-

Confirm File Formats and Software Compatibility:

Ensure the file format (e.g., DWG, DXF, PDF, STEP) is supported by your CAD/CAM software. Use converters or viewers as needed. -

Understand Relevant Standards and Conventions:

Familiarize yourself with applicable standards (e.g., ISO, ASME, DIN) and verify whether the drawing uses First Angle or Third Angle Projection. -

Initial Overview and Title Block Review:

Review the title block for essential details such as part name, revision level, and material. Obtain a general overview of the drawing layout. -

Check for Missing or Incomplete Information:

Identify any gaps in dimensions, tolerances, or notes. Document questions or ambiguities for resolution. -

Validate Dimensions and Tolerances for Manufacturing Feasibility:

Confirm that the specified tolerances are achievable with your equipment and processes. Verify they align with functional and assembly requirements. -

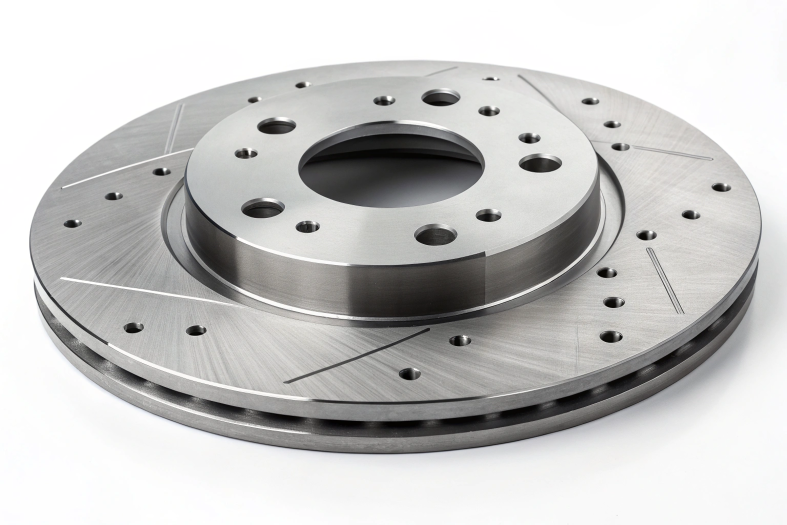

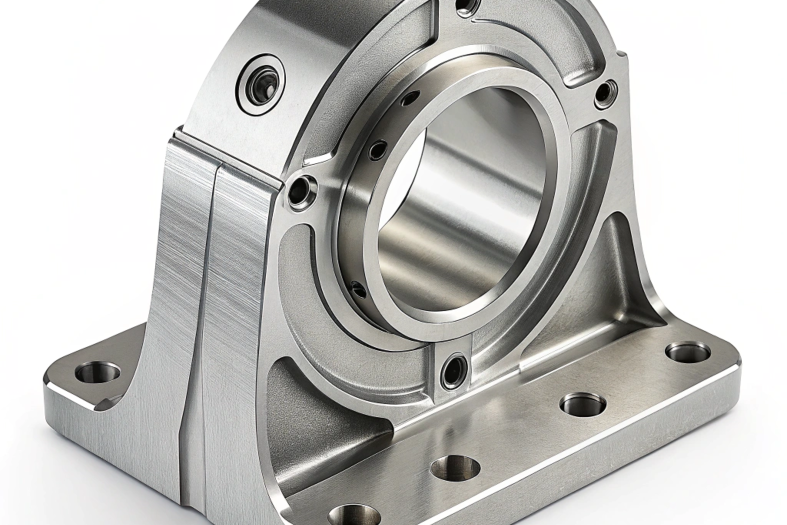

Identify Key Features and Critical Dimensions:

Locate critical features like holes, threads, and mating surfaces. Pay special attention to their tolerances and specifications. -

Assess Material Specifications for Availability and Suitability:

Ensure the material is suitable for the application and available in the required form. -

Clarify Ambiguities and Resolve Questions with the Customer:

Communicate with the customer to address uncertainties or discrepancies. Document all clarifications for reference. -

Document Your Review:

Maintain a record of your observations, questions, and agreements to support future discussions and prevent misunderstandings.

Tools and Software for Viewing Drawings: A Comprehensive Overview

Accurate drawing interpretation begins with selecting the appropriate tools and software. From powerful CAD systems to basic viewers, each option offers unique capabilities suited for different purposes.

CAD Software: Powerful Tools for Design and Analysis

Computer-Aided Design (CAD) software provides a robust suite of tools for working with engineering drawings, including editing, visualization, and analysis.

- Examples:

- AutoCAD (Autodesk): Widely used for 2D and 3D CAD design, offering versatility and advanced features.

- SolidWorks (Dassault Systèmes): Specializes in 3D solid modeling and assembly design.

- Fusion 360 (Autodesk): Cloud-based platform combining CAD, CAM, and CAE tools for collaborative design.

- CATIA (Dassault Systèmes): High-end software for complex surface modeling, used in automotive and aerospace industries.

- NX (Siemens): Advanced CAD/CAM/CAE software for modeling, simulation, and manufacturing.

- Benefits:

- Advanced Editing Tools: Enables precise modifications to drawing geometry.

- 3D Modeling and Visualization: Offers intuitive insights into complex parts.

- Analysis and Simulation: Includes tools for structural analysis and performance simulations.

- Measurement and Inspection Tools: Ensures accurate dimensions and tolerances.

- File Format Compatibility: Supports DWG, DXF, STEP, IGES, and more.

Free Viewers: Basic Viewing and Measurement Capabilities

Free viewers provide an accessible way to view engineering drawings, ideal for quick reviews or for users without CAD expertise.

- Examples:

- DWG TrueView (Autodesk): A free tool for viewing, measuring, and converting DWG/DXF files.

- eDrawings Viewer (SolidWorks): A lightweight viewer for various CAD formats, with markup and measuring capabilities.

- Limitations:

- No Editing Tools: Editing or modifying drawing geometry is not possible.

- Limited Analysis: Lacks advanced analysis and simulation features.

- Restricted Formats: May not support all file types.

PDF Viewers: Convenient for Sharing and Printing

PDF viewers are widely used for sharing and printing drawings while preserving their original layout and formatting.

- Purpose:

- Ideal for viewing, sharing, and printing static representations of drawings.

- Limitations:

- Limited Interactivity: No measurement or modification tools.

- No CAD Data Access: Cannot extract detailed CAD data for analysis or simulation.

Best Practices for Interpreting Drawings: A Systematic Approach

Adopting a structured process ensures accurate and efficient interpretation of engineering drawings.

1. Start with the Title Block

- Action: Review part name, drawing number, revision level, scale, and material details.

- Reason: Provides critical administrative information to avoid errors.

2. Understand the Scale

- Action: Verify the drawing scale to interpret dimensions accurately.

- Example: A scale of 1:2 indicates that dimensions on the drawing are half the actual size.

3. Check for Revisions

- Action: Confirm you are working with the latest revision of the drawing.

- Reason: Outdated revisions can result in incorrect manufacturing.

4. Read All Notes and Specifications

- Action: Carefully examine notes for additional requirements, such as surface finishes, heat treatments, or assembly instructions.

- Reason: Missing critical details can lead to non-conforming parts.

5. Use the Legend

- Action: Refer to the legend to decode symbols, abbreviations, and notations.

- Examples: GD&T symbols, thread indicators, or welding annotations.

6. Ask Questions and Clarify Ambiguities

- Action: Communicate with the customer or drawing creator to resolve unclear details.

- Reason: Clarifying upfront prevents costly rework and delays.

7. Cross-Reference Views and Sections

- Action: Compare multiple views (top, front, side) and sections to visualize the part completely.

- Reason: Ensures all features are understood in relation to the 3D geometry.

8. Consider Manufacturing Processes

- Action: Relate drawing details to feasible manufacturing methods.

- Reason: Identifies potential challenges or optimizations for manufacturability.

Common Mistakes to Avoid: Preventing Costly Errors

Avoiding common mistakes is critical for accurate drawing interpretation and efficient manufacturing.

1. Ignoring the Title Block

- Neglecting critical details, such as revision levels or material specifications, can lead to errors.

2. Misinterpreting Dimensions or Tolerances

- Incorrectly interpreting tolerances can result in parts that fail to meet functional requirements.

3. Overlooking Notes and Specifications

- Missing important notes, such as surface finish requirements or special machining instructions, can lead to defects or rework.

4. Misunderstanding Symbols or Legends

- Failing to interpret GD&T symbols, welding indicators, or thread specifications can cause incorrect manufacturing.

5. Failing to Clarify Ambiguities with the Customer

- Making assumptions instead of resolving questions can lead to costly mistakes and delays.

Summary

Interpreting customer-provided engineering drawings is a critical step in CNC machining and manufacturing, directly impacting product quality, production efficiency, and customer satisfaction. This guide outlines essential techniques, tools, and best practices to ensure accurate and efficient drawing interpretation.

Key elements such as the title block, dimensions and tolerances, and notes and symbols must be thoroughly reviewed to avoid errors. Leveraging powerful CAD tools like AutoCAD, SolidWorks, or Fusion 360 can enhance clarity, while free viewers or PDF viewers provide accessible alternatives for basic viewing needs.

Understanding projection methods, particularly First Angle Projection and Third Angle Projection, is fundamental to interpreting spatial relationships and ensuring compliance with international standards. Following a structured process, including cross-referencing views, clarifying ambiguities, and considering manufacturability, helps resolve uncertainties early and prevents costly mistakes.

By combining systematic review processes, the appropriate use of tools, and a proactive approach to communication, manufacturers can ensure precision, strengthen customer trust, and optimize production workflows. Avoiding common pitfalls, such as ignoring the title block or misinterpreting symbols, is essential for achieving successful outcomes in complex projects.

FAQs:

How to review CAD drawings?

To review CAD drawings effectively:

- Check the Title Block: Verify the part name, drawing number, revision level, and material specifications.

- Inspect Dimensions and Tolerances: Ensure all dimensions and tolerances align with manufacturability.

- Analyze Notes and Symbols: Decode surface finishes, heat treatments, and other annotations using the legend.

- Use CAD Software: Leverage tools like AutoCAD or SolidWorks for detailed 2D and 3D inspections.

- Clarify Ambiguities: Communicate with the client to resolve unclear details.

Where are engineering drawings stored?

Engineering drawings are typically stored in:

- Cloud-Based Platforms: Tools like Autodesk Vault or SolidWorks PDM for secure access and version control.

- Local Servers: In-house storage systems for quicker access, often backed up regularly.

- Physical Archives: Printed drawings stored in cabinets, though this is less common in modern practices.

- Customer Portals: For external collaboration, drawings may be uploaded to shared portals like Dropbox or Google Drive.

Who produces working drawings for the client?

Working drawings are usually produced by:

- Design Engineers: Professionals responsible for translating concepts into detailed drawings.

- Drafting Technicians: Experts in creating precise CAD drawings from specifications.

- Manufacturers: In some cases, manufacturers create shop drawings based on initial designs.

- Freelance CAD Specialists: For smaller projects, independent contractors may be hired to produce drawings.

How to read a section drawing?

To read a section drawing:

- Locate the Cutting Plane: Identify the section line and arrows indicating the cut direction.

- Interpret the View: Focus on the cross-sectional area revealed by the cut, noting internal features.

- Decode Symbols: Use the legend to understand hatch patterns representing materials.

- Cross-Reference Other Views: Relate the section to the top, front, or side views for spatial understanding.

- Use Annotations: Pay attention to dimensions, tolerances, and notes specific to the section.