Hey there! Let me ask you something: Does your production line ever feel like it’s not living up to its potential? Maybe bottlenecks are slowing things down, material waste is cutting into your profits, or inconsistencies are creating quality control nightmares. Frustrating, isn’t it? Especially when you know there has to be a better way.

I’ll show you how CNC machining can revolutionize your production line. We’ll explore how it speeds up operations, slashes waste, and guarantees consistent quality—all while saving you time and money.

Quick Answer:

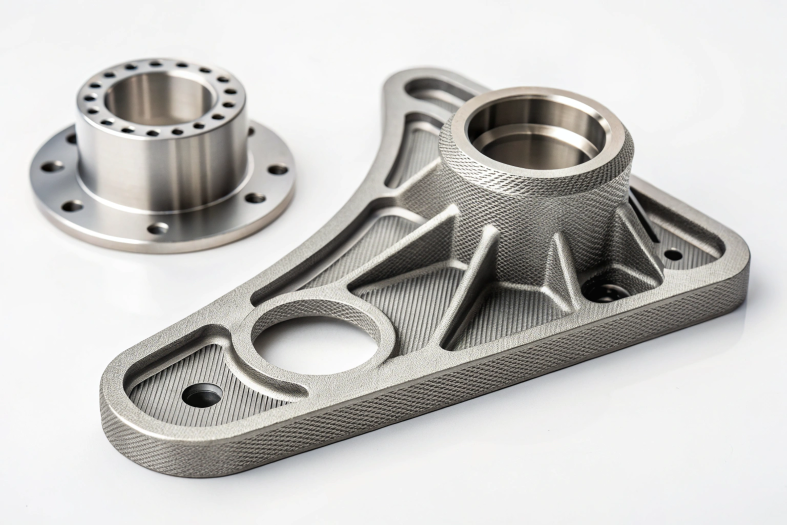

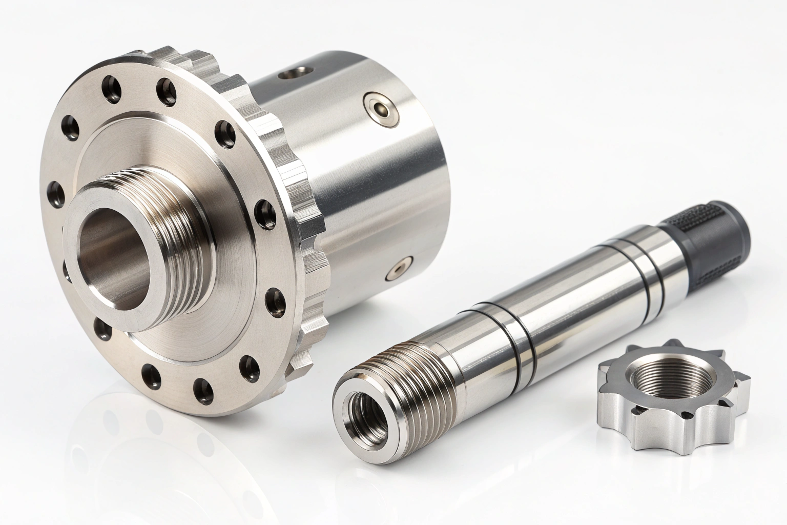

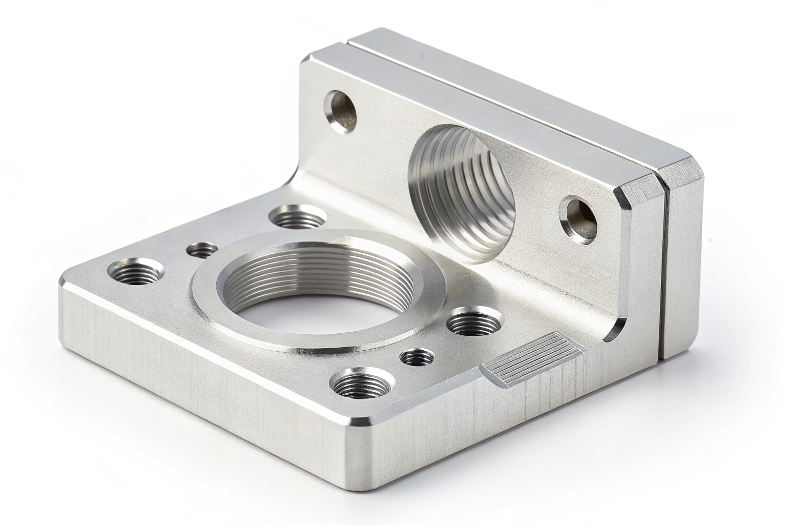

CNC machining optimizes production line efficiency by increasing speed, improving accuracy, and reducing waste. It enables 24/7 autonomous operation, minimizes human error, and ensures consistent part quality with high precision and tight tolerances. CNC systems streamline setup times, support quick program modifications, and integrate seamlessly with CAD/CAM and automated processes. Additionally, CNC machining reduces material waste through precise cutting, enhances scalability with adaptable configurations, and leverages advanced control systems for real-time adjustments.

How CNC Machining Optimizes Production Line Efficiency

CNC (Computer Numerical Control) machining has transformed modern manufacturing by delivering unparalleled precision, speed, and efficiency. Its integration into production lines enables businesses to achieve significant gains in productivity and cost-effectiveness across a wide range of industries. Below is a comprehensive exploration of how CNC machining optimizes production line efficiency.

Increased Speed and Automation

CNC machines are engineered for continuous, autonomous operation, streamlining production and eliminating inefficiencies. These systems reduce reliance on manual labor and improve overall productivity.

- 24/7 Operation: CNC machines operate continuously without the need for breaks, maximizing output and enabling manufacturers to meet tight deadlines and demanding schedules.

- Reduced Labor Costs: Automation minimizes the need for skilled manual intervention, allowing businesses to allocate resources to other critical areas while significantly reducing labor costs.

- Minimized Human Error: Automated control systems eliminate the variability inherent in manual machining, ensuring consistent quality and reducing the likelihood of defects and rework.

- Faster Production Cycles: CNC systems execute complex machining tasks with greater speed and precision than manual methods, reducing cycle times and accelerating turnaround.

Improved Accuracy and Consistency

CNC machining ensures exceptional precision and repeatability, which are essential for maintaining high product quality and reducing waste.

- High Precision and Tight Tolerances: CNC machines deliver tolerances within microns, enabling the production of intricate parts required in industries like aerospace and medical devices.

- Consistent Part Quality: With computer-controlled processes, every part is manufactured to the exact specifications, ensuring uniformity across production runs.

- Reduced Rejects and Rework: CNC accuracy significantly lowers the number of defective parts, saving time and material resources.

- Advanced Control Systems: Real-time feedback and closed-loop systems enable machines to adjust cutting parameters dynamically, maintaining accuracy throughout the machining process.

Reduced Setup and Changeover Times

CNC machining streamlines setup and changeover processes, reducing downtime and enabling greater flexibility in production.

- Quick Program Loading and Modification: CNC programs can be easily loaded, modified, and reused, minimizing setup times and ensuring fast transitions between production runs.

- Automated Tool Changers: Integrated tool changers allow machines to switch tools automatically, reducing manual intervention and setup delays.

- Automated Workholding Systems: Pneumatic and hydraulic fixtures enable fast, secure workpiece clamping, further reducing setup times.

- Flexibility for Small Batch Production: The ease of setup makes CNC machining ideal for small batches and prototypes, allowing manufacturers to adapt quickly to market changes.

Optimized Material Utilization

The precision of CNC machining ensures efficient use of raw materials, leading to cost savings and sustainability.

- Precise Cutting and Minimal Waste: CNC machines cut material with precision, minimizing offcuts and maximizing material yield.

- Nesting Software: Software tools optimize the arrangement of parts on raw material sheets, reducing waste and maximizing efficiency.

- Reduced Scrap and Rework: Accurate machining minimizes material losses due to errors, contributing to cost savings and sustainability.

- Cost Savings and Environmental Impact: Optimized material usage reduces raw material costs and supports environmental sustainability initiatives.

Enhanced Flexibility and Scalability

CNC machines are versatile tools that adapt to a wide variety of production requirements, making them suitable for diverse manufacturing environments.

- Versatile Machining Capabilities: CNC systems handle milling, turning, drilling, and grinding, offering flexibility for complex production needs.

- Scalable Production: Easily adjustable programs allow manufacturers to scale production volumes up or down to meet changing demands.

- Modular Tooling and Fixturing: Modular systems enable quick reconfiguration, accommodating different parts or applications without significant downtime.

- Adaptability to Materials: CNC machines can process metals, plastics, composites, and wood, making them suitable for various industries and products.

Integration with Other Manufacturing Processes

CNC machining integrates seamlessly with other digital and automated manufacturing technologies, creating a cohesive and efficient production environment.

- CAD/CAM Integration: Direct links between CNC machines and CAD/CAM software ensure efficient design-to-production workflows and reduced lead times.

- Robotics Integration: CNC systems can collaborate with robotic arms for tasks like part loading/unloading and material handling, enhancing automation and throughput.

- Automated Assembly Integration: Machined parts produced with CNC precision integrate perfectly into automated assembly lines, ensuring flawless final products.

- Digital Data Exchange and Communication Protocols: Standardized data exchange formats facilitate real-time collaboration between CNC machines, manufacturing systems, and quality control tools.

Specific Strategies for Optimizing CNC Machining for Efficiency

Beyond the inherent advantages of CNC machining, several key strategies can further optimize its efficiency within a production line. These strategies focus on maximizing machine uptime, minimizing waste, and ensuring consistent high-quality output. Below is a comprehensive guide combining various aspects of optimization.

Proper Tool Selection and Maintenance

The choice and upkeep of cutting tools directly impact machining efficiency, surface finish, and tool longevity.

- Material-Specific Tool Selection: Selecting tools with appropriate geometries, coatings, and materials for the workpiece material is paramount. For instance, carbide tools are ideal for machining hardened steels, while high-speed steel (HSS) tools are suitable for softer materials. Coatings such as Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN) enhance tool wear resistance and allow for higher cutting speeds.

- Tool Geometry Optimization: Proper tool geometry, including rake angles, clearance angles, and cutting edge radius, influences chip formation, cutting forces, and surface finish. Optimizing these parameters can significantly improve machining performance.

- Regular Tool Inspection and Replacement: Regularly inspecting tools for wear, damage, or dullness ensures consistent cutting efficiency and prevents damage to the workpiece. Sharpening or replacing worn tools maintains optimal performance.

- Tool Management Systems: Implementing a tool management system helps track tool inventory, monitor tool usage, and schedule maintenance, reducing downtime and ensuring the availability of suitable tools.

- Tool Presetting: Using a tool presetter offline allows accurate measurement of tool length and diameter before installation, reducing setup time and ensuring precision during machining.

Optimizing Cutting Parameters

Careful selection of cutting parameters—speed, feed, and depth of cut—is essential to achieving optimal machining results.

- Cutting Speed (Vc): The speed at which the cutting tool moves relative to the workpiece. Higher cutting speeds generally improve material removal rates but may increase tool wear.

- Feed Rate (f): The distance the cutting tool advances along the workpiece per revolution or per tooth. Optimizing feed rates balances material removal efficiency with surface finish quality.

- Depth of Cut (ap/ae): The depth of material removed in a single pass. While deeper cuts increase material removal rates, they also require greater cutting power and generate more heat.

- Cutting Data Tables and Software: Using cutting data tables or CAM software helps determine the best parameters based on material, tool type, and desired finish.

- Adaptive Control: Advanced CNC machines can adjust cutting parameters in real-time using sensors, optimizing performance and preventing tool breakage.

Efficient Workholding and Fixturing

Secure and precise workholding is crucial for maintaining machining accuracy and preventing workpiece movement during operations.

- Fixture Design and Selection: Selecting appropriate fixtures, such as vises, chucks, collets, or custom-designed systems, ensures workpiece stability and precision.

- Quick-Change Fixtures: These fixtures reduce setup and changeover times, especially for small batch production or frequent part changes.

- Modular Fixturing Systems: Modular systems allow rapid reconfiguration for different parts or operations, offering flexibility and adaptability.

- Zero-Point Clamping Systems: These systems provide precise and repeatable workpiece positioning, minimizing setup time and enhancing machining accuracy.

- Proper Clamping Force: Ensuring the correct clamping force prevents workpiece movement without causing distortion.

Programming Optimization

Efficient CNC programming is key to maximizing machine utilization and minimizing cycle times.

- Optimized Toolpaths: Generating efficient toolpaths using CAM software minimizes unnecessary tool movements, reducing cycle times and improving material removal efficiency.

- Subprograms and Macros: Reusing code segments with subprograms and macros simplifies programming and shortens program length.

- Canned Cycles: Utilizing built-in canned cycles for operations like drilling, tapping, and boring simplifies programming and reduces errors.

- Simulation and Verification: Simulating CNC programs before execution helps identify potential issues, ensuring error-free and efficient operations.

- High-Speed Machining Techniques: Strategies like high-feed milling and trochoidal milling enhance cutting efficiency and reduce cycle times for specific applications.

Preventive Maintenance and Machine Monitoring

Proactive maintenance and real-time monitoring ensure machines operate at peak efficiency and avoid costly downtime.

- Regular Maintenance Schedules: Routine cleaning, lubrication, and inspection of machine components prevent unexpected breakdowns and maintain optimal performance.

- Machine Monitoring Systems: Real-time monitoring of parameters like spindle load, vibration, and temperature allows early detection of potential problems, enabling timely interventions.

- Predictive Maintenance: Leveraging data analytics and machine learning predicts failures before they occur, allowing proactive measures to minimize downtime.

- Proper Machine Calibration: Regular calibration of CNC machines ensures consistent accuracy and repeatability in machining operations.

Conclusion

CNC machining is undeniably a game-changer for modern manufacturing, offering unmatched precision, efficiency, and versatility. By understanding its strengths and implementing specific strategies like proper tool selection, optimizing cutting parameters, and proactive maintenance, you can truly unlock its full potential.

If you're exploring ways to boost your production line efficiency or need reliable CNC machining services, let’s connect! At PROMACHINED, we specialize in delivering tailored CNC machining solutions that align with your unique business needs.

Check out more about what we can do at www.promachined.com. Feel free to drop me a message—just like chatting with a friend. I’d love to hear about your projects and see how we can help you optimize your processes!

Talk soon!

FAQ:

How can I increase productivity in a CNC machine?

Increasing CNC machine productivity involves optimizing cutting parameters, minimizing downtime, and leveraging automation. Here’s how:

- Optimize Cutting Parameters: Use cutting speed, feed rate, and depth of cut tailored to the material and tooling. Tools like CAM software and adaptive controls can fine-tune these for maximum efficiency.

- High-Performance Tools: Invest in high-quality tools with appropriate coatings for durability and efficiency. Regular tool maintenance and timely replacement are key.

- Minimize Downtime: Quick-change fixtures, modular fixturing, and automated tool changers speed up setups and transitions.

- Streamline Toolpaths and Programming: Efficient toolpaths, subprograms, and macros reduce cycle times. CAM software helps optimize strategies like trochoidal milling.

- Use Automation: Robotic loaders, pallet changers, and automated part transfer systems allow for continuous, hands-free operation.

- Preventive Maintenance: Regularly inspect and service machines to prevent breakdowns and ensure consistent performance.

How can CNC machines be used for greener manufacturing?

CNC machines contribute to sustainable practices in multiple ways:

- Minimized Material Waste: Precise cutting and nesting software optimize material use.

- Energy Efficiency: CNC systems consume less energy per part due to efficient processes. IoT integration can further optimize energy use.

- Reduced Scrap: High precision eliminates defects, cutting waste.

- Sustainable Materials: CNC machines can process recyclable and eco-friendly materials.

- Closed-Loop Coolant Systems: Reduce coolant usage and waste with closed-loop systems.

Is CNC machining suitable for mass production?

Yes, CNC machining is ideal for mass production:

- Precision and Repeatability: CNC machines ensure consistent quality across large production runs.

- Automation: Automated processes make high-volume production efficient.

- Cost Efficiency: Initial setup costs are offset by lower costs per part in large runs.

- Flexibility: CNC programming allows for quick adjustments to part designs without significant retooling.

How do you maximize CNC production output?

To maximize CNC production output:

- Optimize Machining Parameters: Ensure cutting speeds and feed rates are tuned for efficiency and tool longevity.

- Use High-Speed Machining Techniques: Techniques like high-feed milling reduce cycle times.

- Automate Material Handling: Robotic loaders and automated transfer systems keep machines running continuously.

- Efficient Workholding: Quick-change and zero-point clamping systems minimize setup time.

- Preventive Maintenance: Regular machine checks and monitoring systems prevent unexpected downtime.

- Apply Lean Manufacturing: Techniques like 5S and Kaizen streamline workflows, reduce waste, and boost efficiency.