You know how frustrating it can be when CNC path planning gets messy—too much back-and-forth, wasted time, and tools wearing out faster than they should. I’ve been there, and I’ll tell you, the right software makes all the difference. With a few smart tweaks, you can optimize those paths, save time, and get your machines running smoother than ever. Let’s dive into how to make it happen!

Quick Answer:

To optimize CNC processing path planning, analyze machine and material factors, use advanced CAM software with strategies like trochoidal milling, and simulate toolpaths to improve precision, efficiency, and tool life.

Key Factors Influencing Path Optimization in Machining

Efficient path optimization in machining is crucial for minimizing production time, maximizing tool life, and achieving desired part quality. Several key factors influence this process, demanding careful consideration during Computer-Aided Manufacturing (CAM) programming.

Machine Capabilities

The physical limitations and capabilities of the machine tool play a significant role in determining optimal toolpaths. These include:

-

Spindle Speed and Power

The maximum spindle speed (RPM) and available power dictate the feasible cutting speeds and material removal rates. High spindle speeds are advantageous for faster cutting, especially with smaller diameter tools. Spindle power ensures the machine maintains speed under load during heavy cuts. Advanced spindles offer greater flexibility for diverse materials and operations. -

Feed Rates and Axis Acceleration/Deceleration

Maximum feed rates and the machine’s ability to accelerate and decelerate along its axes directly impact efficiency. High acceleration/deceleration rates reduce non-cutting time but must be balanced to avoid inducing vibrations that compromise precision. -

Tool Changer Capacity and Speed

Automatic tool changers (ATC) play a crucial role in operations requiring multiple tools. A higher capacity and faster tool change times minimize downtime, enabling smoother workflows for complex machining tasks. -

Machine Stiffness and Rigidity

Structural stiffness determines the machine’s ability to withstand cutting forces without excessive deflection or vibration. High rigidity allows for aggressive cutting parameters, improving both efficiency and surface finish. -

Axis Travel Limits

The maximum travel range of each axis defines the workpiece size and restricts the feasible toolpaths. CAM software must respect these limits while optimizing paths to utilize the machine's full capabilities.

Material Properties

The characteristics of the workpiece material significantly influence cutting conditions and path optimization:

-

Hardness and Strength

Harder and stronger materials demand lower cutting speeds and feed rates to reduce tool wear and breakage. These materials also generate higher cutting forces and heat, requiring advanced cooling and lubrication strategies. -

Machinability

Machinability measures how easily a material can be machined. Factors like hardness, ductility, and thermal conductivity influence machinability. Poorly machinable materials may require specialized tools and conservative parameters. -

Brittleness

Brittle materials, such as ceramics, are prone to chipping or fracturing during machining. This necessitates controlled cutting forces and smooth tool engagement strategies to minimize damage. -

Thermal Conductivity

Materials with low thermal conductivity, such as titanium, retain heat, increasing the risk of tool wear and workpiece distortion. Optimized paths often incorporate cooling strategies to manage heat effectively.

Tool Geometry and Selection

The choice of cutting tool is critical for effective machining. Key considerations include:

-

Tool Material

Tool materials like high-speed steel (HSS), carbide, ceramics, and diamond offer varying levels of hardness, wear resistance, and toughness. The workpiece material and desired machining parameters influence the selection. -

Tool Geometry

- Diameter: Larger-diameter tools allow for higher material removal rates but may require greater spindle power.

- Length: Longer tools are prone to deflection, which can compromise accuracy. Shorter tools are more stable and suitable for high-precision operations.

- Cutting Edge and Rake Angles: These angles influence chip formation, cutting forces, and surface finish. For instance, positive rake angles reduce cutting forces in soft materials, while neutral or negative angles suit harder materials.

-

Tool Coatings

Coatings such as TiN, TiAlN, and DLC enhance wear resistance, reduce friction, and improve heat dissipation, extending tool life and performance.

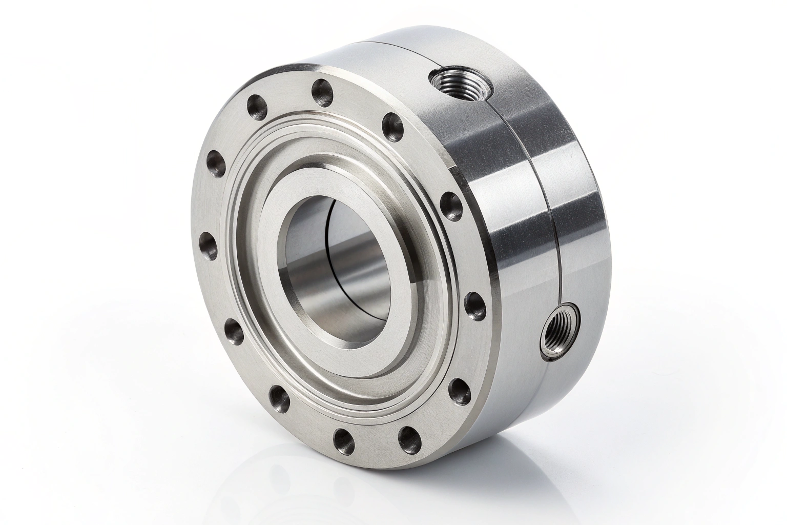

Tolerances and Surface Finish Requirements

The required precision and surface quality of the finished part dictate the necessary level of path optimization:

-

Dimensional Tolerances

Tight tolerances necessitate precise tool positioning and control of machining errors. Achieving this often involves multiple finishing passes and compensating for tool wear. -

Surface Roughness

Achieving fine surface finishes requires optimized paths with smaller stepovers, higher cutting speeds, and sharp cutting edges. Applications like aerospace and medical components often demand such meticulous finishes. -

Form Tolerances (e.g., Roundness, Flatness)

Specific form requirements necessitate careful path planning to minimize deviations. This may involve specialized toolpaths, compensation for machine inaccuracies, and adaptive control systems.

Software Tools and Techniques for Path Optimization in Machining

Effective path optimization relies heavily on sophisticated software tools and advanced techniques. These tools empower manufacturers to generate efficient toolpaths, simulate machining processes, and verify the resulting part quality. Here is an integrated breakdown of the key elements:

CAM Software (Computer-Aided Manufacturing)

Modern CAM software is indispensable for path planning and optimization, providing a wide range of functionalities to address the needs of diverse machining operations. Key features include:

-

Advanced Toolpath Generation Strategies

CAM systems offer various toolpath strategies tailored to specific machining operations and part geometries:- Roughing Strategies: Techniques like pocketing, adaptive clearing, and trochoidal milling ensure efficient material removal, minimizing machining time.

- Finishing Strategies: Strategies such as contouring, parallel finishing, and spiral milling achieve high-quality surface finishes.

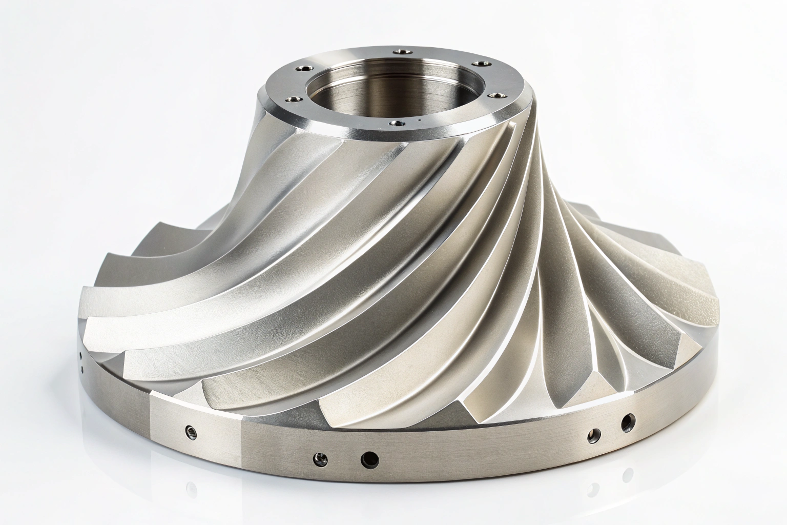

- Multi-Axis Machining: Support for 3-axis, 4-axis, and 5-axis machining enables the production of intricate parts with complex geometries.

-

Material Removal Simulation

Visualizing the material removal process helps identify potential issues like gouging, collisions, and excessive cutting forces before production. -

Tool Library and Management

Integrated tool libraries allow users to define and manage cutting tools, including geometry, materials, and cutting parameters, ensuring consistent and efficient operations. -

Post-Processing

CAM software generates machine-specific G-code or other control codes to instruct CNC machines, ensuring compatibility and efficiency. -

User-Friendly Interface

Intuitive workflows and interfaces streamline the programming process, making it accessible to machinists and engineers.

Examples of widely used CAM software include:

- Mastercam: Comprehensive features for milling and turning.

- NX CAM: Advanced features for complex and high-precision machining.

- PowerMill: Optimized for high-speed and multi-axis machining.

- GibbsCAM: Known for versatility and ease of use across various machining applications.

- Fusion 360: A cloud-based platform with integrated CAD, CAM, and CAE capabilities.

Path Generation Algorithms

Efficient toolpath generation is at the heart of CNC path optimization. Key algorithms include:

-

Constant Z (Z-Level or Waterline)

Ideal for 3D milling, this strategy creates horizontal slices at constant Z levels, effectively machining complex surfaces. -

Parallel (Raster)

The tool moves in parallel lines, making it suitable for roughing and finishing flat or gently curved surfaces. -

Contouring (Profile)

The tool follows the contours of the part, making it perfect for finishing edges and creating smooth transitions. -

Spiral/Helical

These paths are often used for pocketing and hole-making operations, improving chip evacuation and reducing cutting forces. -

Trochoidal Milling

A circular toolpath combined with a forward feed reduces cutting forces, enabling faster cutting speeds and improving tool life, especially for hard materials.

Simulation and Verification

Simulation and verification are critical to ensuring safe and efficient machining:

-

Toolpath Simulation

Simulating the toolpath provides a visual representation of tool movements, helping to identify potential collisions and inefficiencies. -

Material Removal Simulation (Stock Simulation)

Simulating material removal ensures the final part shape and dimensions meet design specifications. -

Machine Simulation

Simulating machine kinematics and dynamics provides an accurate prediction of machining outcomes, including tool deflection and machine vibrations. -

G-Code Verification

Specialized software checks the G-code for errors, ensuring it executes correctly on the CNC machine and adheres to specifications.

Optimization Algorithms

Advanced algorithms fine-tune toolpaths for maximum efficiency and precision:

-

Genetic Algorithms

These iterative methods mimic natural selection to optimize toolpaths by evaluating and combining the best-performing solutions. -

Simulated Annealing

Inspired by the cooling process of metals, this algorithm finds optimal solutions by reducing the probability of accepting suboptimal paths over time. -

Particle Swarm Optimization

This population-based algorithm uses "particles" that share information about their best positions to converge on an optimal solution. -

Cutting Parameter Optimization

Algorithms optimize cutting speeds, feed rates, and depths of cut to minimize machining time while maintaining tool life and surface quality.

Cloud-Based CAM Solutions

Cloud-based CAM platforms offer several transformative advantages for modern machining:

-

Collaboration

Teams can share data and collaborate in real time, regardless of location, enhancing productivity and communication. -

Scalability

Cloud-based platforms handle complex projects and large datasets effortlessly, scaling as needed. -

Accessibility

Users can access CAM software and data from any device with an internet connection, enabling flexibility. -

Computational Power

Cloud platforms provide access to high-performance computing resources, accelerating simulations and calculations.

Optimization Strategies for Machining Path Planning

Effective path optimization involves implementing various strategies that consider toolpaths, cutting parameters, and potential collisions. These strategies aim to maximize efficiency, minimize machining time, improve surface finish, and extend tool life.

Toolpath Strategies

The choice of toolpath pattern significantly impacts machining performance. Several strategies are commonly employed:

-

Zigzag (Raster)

The tool moves back and forth in straight lines across the workpiece. This simple strategy is widely used for roughing operations on flat surfaces. However, abrupt direction changes can induce vibrations, potentially affecting surface finish. -

Contour (Profile)

The tool follows the contours of the part, making it ideal for finishing edges and creating smooth transitions. This strategy provides excellent surface finish but may be less efficient for machining large areas. -

Spiral/Helical

The tool follows a continuous spiral or helical path, often used for pocketing and hole-making. This strategy promotes efficient chip evacuation, reduces cutting forces, and avoids abrupt direction changes, resulting in improved surface finish. -

Trochoidal Milling

Trochoidal milling involves circular toolpaths combined with forward feed. This strategy is highly effective for machining hard materials and deep cavities. Benefits include:- Constant Tool Engagement: Maintains consistent cutting forces, reducing stress on the tool.

- Improved Chip Evacuation: Ensures clean cutting zones, preventing material buildup.

- Extended Tool Life: Reduces wear by minimizing heat and force fluctuations.

-

Adaptive Clearing

This strategy dynamically adjusts the toolpath based on the remaining material, maintaining a constant material removal rate. It significantly improves roughing efficiency, especially for complex 3D shapes. -

Rest Machining

Targets areas of material left uncut by previous operations, focusing on precise removal in specific regions. This improves efficiency by addressing only the areas that need further machining.

Feed Rate Optimization

Optimizing the feed rate ensures efficient material removal while maintaining tool life and surface quality. Factors to consider include:

-

Material Properties

Harder materials typically require lower feed rates to prevent excessive tool wear or breakage. Softer materials can tolerate higher feed rates for faster machining. -

Tool Strength and Geometry

The tool's material, diameter, and geometry determine its ability to handle feed rates. Tools with smaller diameters or less robust geometries necessitate lower feed rates to avoid damage. -

Machine Constraints

The machine's maximum feed rate, axis acceleration/deceleration, and stability set upper limits for feed rate optimization. -

Cutting Conditions

Depth of cut, width of cut, and cutting speed must be considered when determining the optimal feed rate. -

Surface Finish Requirements

High-quality finishes often require slower feed rates to minimize tool marks and achieve finer surfaces.

Modern CAM software incorporates algorithms that calculate feed rates based on these factors, ensuring the highest possible efficiency without compromising safety or quality.

Tool Engagement Optimization

Tool engagement optimization minimizes the time the tool actively cuts material, reducing cutting forces, heat generation, and tool wear. Key approaches include:

-

Optimized Toolpaths

Strategies such as trochoidal milling and adaptive clearing ensure consistent material removal rates while reducing tool engagement stress. -

High-Speed Machining (HSM)

HSM techniques involve higher cutting speeds and reduced feed rates, decreasing cutting forces and heat while maintaining efficiency. -

Proper Tool Selection

Selecting tools with appropriate geometry and material for specific operations enhances cutting performance and reduces engagement time.

These methods not only improve machining accuracy but also extend tool life and reduce production time.

Avoiding Collisions

Collision avoidance is critical to safe and efficient machining. Strategies include:

-

Toolpath Simulation

Simulating tool movements allows machinists to identify potential collisions between tools, workpieces, fixtures, or machine components before production begins. -

Machine Simulation

Incorporating machine kinematics and dynamics in simulations provides a more accurate prediction of machining outcomes and potential issues. -

Fixture and Workpiece Modeling

Precise modeling of fixtures and workpieces within CAM software ensures accurate collision detection and better path planning. -

Clearance Zones

Defining clearance zones around fixtures and workpieces helps maintain safe distances between tools and critical components. -

Automatic Collision Avoidance

Modern CAM software includes advanced features that automatically adjust toolpaths to avoid collisions, ensuring safety and efficiency during machining.

Advanced Optimization Techniques in Machining

Beyond standard optimization strategies, advanced techniques significantly enhance machining efficiency, precision, and automation. These methods address complex scenarios and leverage real-time data to deliver superior results, enabling manufacturers to tackle intricate projects with greater reliability and effectiveness.

Adaptive Control

Adaptive control systems dynamically adjust machining parameters based on real-time feedback from sensors, moving beyond pre-programmed settings. These systems come in two primary types:

-

Adaptive Control Optimization (ACO)

ACO systems aim to optimize specific performance metrics, such as maximizing material removal rate (MRR) or minimizing machining time. They continuously adjust parameters like feed rate and spindle speed, ensuring optimal performance while adhering to constraints such as cutting force, tool wear, and surface finish. -

Adaptive Control Constraint (ACC)

ACC systems focus on maintaining specific process variables within predefined limits. For example, they monitor cutting force and adjust feed rates to prevent exceeding maximum thresholds, protecting the tool and machine from potential damage.

Key Benefits of Adaptive Control:

- Increased Productivity: Real-time optimization reduces machining time, boosting throughput.

- Improved Tool Life: Maintaining controlled cutting forces and temperatures extends tool life, lowering costs.

- Enhanced Part Quality: Stable cutting conditions lead to better surface finishes and dimensional accuracy.

- Reduced Operator Intervention: Automation minimizes the need for manual adjustments, freeing operators to focus on other tasks.

Adaptive control is particularly effective in machining hard-to-machine materials or scenarios where consistent quality and reduced cycle times are critical.

Multi-Axis Machining

Multi-axis machining, involving more than three linear axes, expands the possibilities for creating complex geometries. However, it introduces challenges that require advanced optimization techniques:

-

Tool Orientation Management

Continuously changing tool orientation relative to the workpiece requires precise adjustments. Optimization ensures the tool maintains the ideal cutting angle for smooth surface finishes and effective material removal. -

Collision Avoidance

With additional axes, the risk of collisions between the tool, workpiece, and machine components increases. Advanced CAM software uses real-time simulations and algorithms to detect and prevent collisions. -

Toolpath Generation

Sophisticated algorithms generate efficient toolpaths that account for the machine’s kinematics and ensure smooth, precise movements. -

Simultaneous Axis Control

Coordinating multiple axes simultaneously requires synchronization to avoid inaccuracies and ensure seamless transitions.

Benefits of Multi-Axis Machining:

- Reduced Setups: Multi-axis machining allows complex parts to be completed in a single setup, improving accuracy and reducing setup time.

- Enhanced Surface Finishes: Optimized tool orientation achieves superior finishes, particularly on intricate surfaces.

- Increased Design Freedom: Enables the production of parts with complex shapes and undercuts that are impossible with three-axis machining.

Multi-axis machining is essential in industries like aerospace, automotive, and medical device manufacturing, where precision and complexity are paramount.

Material Removal Rate (MRR) Optimization

Material removal rate (MRR) measures the volume of material removed per unit of time. Maximizing MRR improves productivity but requires balancing speed with quality and tool longevity.

-

Cutting Parameters

Adjusting cutting speed, feed rate, and depth of cut increases MRR. For example:- Higher feed rates remove material faster but may compromise surface finish.

- Deeper cuts improve productivity but require robust machine power and rigidity.

-

Tool Geometry and Material

Tools with appropriate geometries, such as sharper cutting edges or optimized rake angles, enhance material removal efficiency. Using tools made from advanced materials like carbide or coated tools extends durability under high MRR conditions. -

Machine Capabilities

The machine’s spindle power, rigidity, and feed rate capabilities set the limits for safe and effective MRR. -

Surface Finish Requirements

High MRR may generate rougher surfaces. Balancing cutting parameters to achieve acceptable finishes without sacrificing speed is critical.

Strategies for Optimizing MRR:

- Trochoidal Milling: Maintains constant tool engagement, reducing cutting forces and enabling higher cutting speeds.

- Adaptive Clearing: Dynamically adjusts toolpaths to ensure consistent material removal rates.

- Thermal Management: Effective cooling prevents heat buildup, which can degrade tool performance and part accuracy.

Advanced CAM software integrates these strategies, offering simulations and predictive models to maximize MRR while maintaining quality, tool life, and machine stability.

Conclusion: Let’s Chat About CNC Path Optimization

Alright, we’ve covered a lot about optimizing CNC processing path planning through software. From understanding the core concepts of path optimization to diving deep into advanced techniques like adaptive control and multi-axis machining, I hope this has given you a solid foundation to improve your machining processes.

If you’re like me, you’re always looking for ways to streamline operations and get the best results from your CNC setups. Investing in modern CAM software, experimenting with strategies like trochoidal milling, and leveraging cloud-based solutions can truly make a difference.

If you’re curious about applying these ideas to your projects or want to explore more about CNC machining, feel free to check out my website at www.promachined.com. I’d love to hear your thoughts or chat about how we can solve machining challenges together. Let’s connect and create something amazing!

Looking forward to hearing from you!

Cheers,

Your friend in CNC machining

FAQ:

How to increase productivity in a CNC machine?

To increase productivity in a CNC machine:

- Optimize Toolpaths: Use advanced CAM software to generate efficient toolpaths like trochoidal milling or adaptive clearing. These strategies reduce machining time and improve tool life.

- Use High-Speed Machining (HSM): Increase spindle speeds and reduce cutting forces to enable faster material removal while maintaining precision.

- Minimize Tool Changes: Group similar operations to reduce tool changeovers and setup times, maximizing machining efficiency.

- Upgrade Tooling: Invest in high-performance tools with advanced coatings that enhance durability and cutting efficiency.

- Proper Workholding: Ensure rigid and secure workholding to prevent vibrations, enabling higher cutting parameters and maintaining machining accuracy.

- Preventative/Scheduled Maintenance: Implement a proactive maintenance schedule to minimize downtime, reduce unexpected failures, and ensure consistent machine performance.

- Automate Workflows: Incorporate automation, such as robotic loading/unloading and tool presetters, to reduce manual intervention and increase throughput.

What is a CNC toolpath?

A CNC toolpath is the programmed trajectory that a cutting tool follows to remove material and shape a workpiece. Toolpaths are generated using CAM software and define:

- Movement Types: Linear, circular, or helical movements that guide the tool’s motion.

- Strategies: Roughing (material removal), finishing (precise shaping), and adaptive paths (optimized cutting efficiency).

- Machine Coordination: The specific movements of the CNC machine’s axes to achieve the desired geometry.

Efficient toolpath planning directly impacts machining accuracy, speed, and tool life. These toolpaths are translated into machine code (G-code or M-code), which the CNC machine interprets and executes to perform the desired operations.

What is process planning for CNC machining?

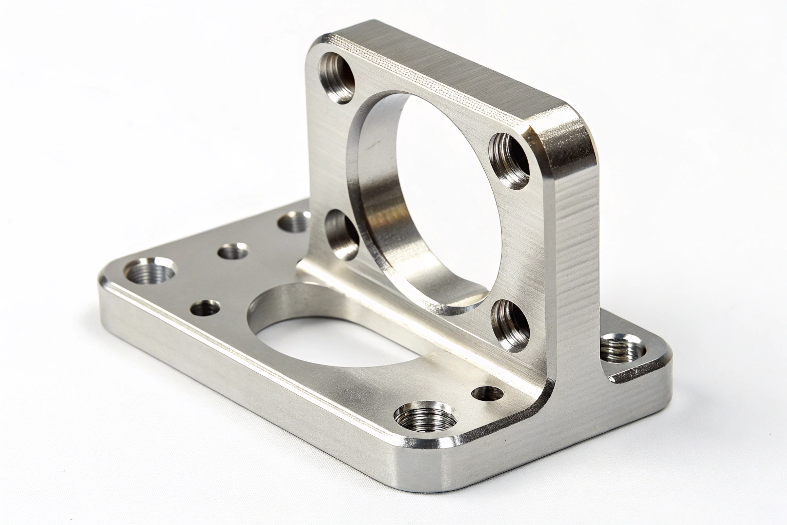

Process planning for CNC machining involves creating a structured workflow to transform raw material into a finished product. It ensures efficiency, accuracy, and consistency in manufacturing. Key steps include:

- Material Selection: Choosing the appropriate material based on the design and performance requirements.

- Tool Selection: Identifying the right cutting tools for the specific operations and materials.

- Fixture Design/Selection: Choosing or designing appropriate fixtures to securely hold the workpiece during machining, ensuring stability and precision.

- Operation Sequencing: Defining the optimal order of machining steps, such as roughing, semi-finishing, and finishing.

- Toolpath Generation: Using CAM software to create efficient toolpaths tailored to the machine and workpiece geometry.

- Quality Assurance: Setting dimensional tolerances, surface finish requirements, and inspection processes to verify that parts meet specifications.

How to speed up CNC machining?

To speed up CNC machining:

- Optimize Cutting Parameters: Systematically increase feed rates and spindle speeds within safe operating ranges determined by tool specifications, material properties, and machine capabilities. Proper optimization prevents tool wear, maintains surface finish, and avoids machine damage.

- Use Advanced Toolpaths: Employ high-efficiency strategies like trochoidal milling or adaptive clearing to reduce cutting forces and maximize material removal rates.

- Upgrade Tools and Materials: Use coated carbide tools or other advanced materials that allow for higher cutting speeds and better heat resistance.

- Reduce Non-Cutting Time: Streamline tool changes, minimize setup times, and optimize machine repositioning to increase overall efficiency.

- Coolant Optimization: Utilize appropriate coolant types and application methods for effective heat dissipation and chip evacuation, enabling higher cutting parameters and reducing thermal stress.

- Automate Processes: Incorporate robotic loading/unloading systems and automated part handling to save time and reduce manual errors.