Choosing the right CNC processing plant can be challenging, especially when you’re unsure about their technical capabilities. A poor decision might lead to delays, subpar quality, and increased costs for your project. However, by focusing on essential factors like machinery, expertise, and certifications, you can secure a reliable partner and achieve high-quality results.

Key Factors to Consider:

-

Machinery and Technology:

Look for advanced CNC machines such as 3-axis, 4-axis, and 5-axis mills, CNC lathes, and specialized equipment like grinders or EDM. Ensure the machines are modern, well-maintained, and capable of meeting your project's technical demands. -

Materials and Processes:

Assess the plant’s expertise with materials like aluminum, steel, titanium, and Inconel. Confirm their ability to meet tight tolerances and specific surface finish requirements critical for precision parts. -

Software and Programming:

Verify the use of advanced CAD/CAM software, simulation tools, and skilled programmers to ensure efficient machining and collision-free processes. -

Quality Control:

Check for robust inspection equipment such as CMMs and optical comparators. Ensure adherence to quality certifications like ISO 9001 or AS9100 and inquire about their calibration and inspection protocols. -

Engineering and Support:

Evaluate their ability to provide design-for-manufacturability (DFM) feedback, process optimization, and responsive communication to ensure smooth project management. -

Practical Validation:

- On-Site Visits: Observe the facility’s cleanliness, equipment condition, and workflow organization.

- Sample Parts: Request samples to evaluate dimensional accuracy, surface finish, and overall quality.

- References and Reviews: Contact previous clients and check online reviews to validate their reliability and customer satisfaction.

Key Areas to Evaluate

Evaluating the technical capabilities of a CNC processing plant involves assessing critical aspects such as equipment, materials, processes, software, quality control, and engineering support. A thorough understanding of these areas ensures a reliable and efficient partnership for your manufacturing needs.

Machining Equipment and Technology

Types of CNC Machines

A diverse range of CNC machines is essential for handling varying levels of complexity in part production:

-

3-Axis Milling Machines:

These machines operate along three linear axes (X, Y, Z) and are well-suited for simpler parts with planar or prismatic features. However, they require multiple setups for complex geometries, potentially increasing machining time and introducing inaccuracies. -

4-Axis Milling Machines:

Adding a rotary axis (typically the A-axis) enables the machining of cylindrical workpieces and indexing to different faces. This reduces setup time and increases versatility compared to 3-axis machines. -

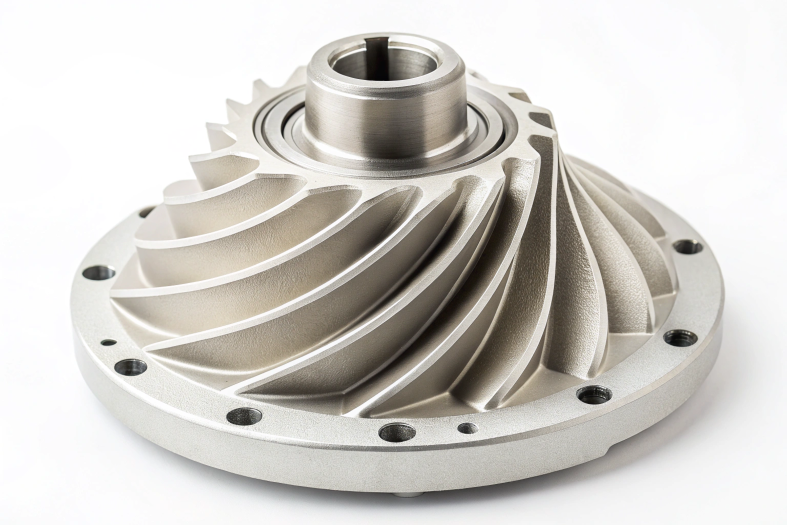

5-Axis Milling Machines:

These machines offer simultaneous movement along three linear axes and two rotational axes (A and B or C), allowing for the production of complex geometries, undercuts, and intricate contours in a single setup. Industries such as aerospace, medical, and mold-making often rely on 5-axis machines for parts like turbine blades, impellers, and orthopedic implants. -

CNC Lathes and Turning Centers:

Designed for rotating workpieces, CNC lathes are ideal for cylindrical or symmetrical parts such as shafts, rods, and discs. Advanced turning centers include live tooling for milling, drilling, and tapping, increasing their versatility. -

Specialized Machines (e.g., Grinders, EDM, Swiss-type):

- Grinders: Achieve fine surface finishes and tight tolerances, particularly on hardened materials. Common types include surface grinders, cylindrical grinders, and centerless grinders.

- Electrical Discharge Machining (EDM): Uses electrical sparks to erode material. Wire EDM is suitable for cutting intricate profiles, while sinker EDM is used for creating cavities and detailed forms. EDM excels in machining hard materials and creating shapes not possible with traditional methods.

- Swiss-type Lathes: Ideal for small, complex, high-precision parts. The sliding headstock design minimizes deflection, enabling precise machining of slender components.

Machine Age and Condition

Modern machines offer advantages such as higher spindle speeds, improved feed rates, and advanced control systems for smoother movements. Evaluate the following:

- Maintenance Records: Regular maintenance ensures accuracy and prevents downtime. A commitment to preventative maintenance reflects reliability.

- Technological Features: Look for automated tooling systems, higher cutting speeds, and the ability to handle advanced materials.

Automation and Tooling

Automation and tooling significantly impact productivity and consistency:

- Automated Tool Changers (ATCs): Enable rapid tool switching to reduce setup times.

- Pallet Systems: Allow for pre-loading and unloading of workpieces to maximize machine utilization.

- Robotic Loading/Unloading: Enhances efficiency and reduces manual labor.

- Cutting Tools: High-performance cutting tools improve surface finish, accuracy, and machining speed.

Materials and Processes

Range of Materials Machined

A CNC plant should demonstrate proficiency in machining a variety of materials:

- Common Materials: Aluminum, steel, brass, copper, and plastics such as ABS and polycarbonate.

- Exotic Materials: Titanium, Inconel, and nickel-based superalloys often require specialized tooling and expertise. These materials are critical for aerospace, medical, and high-performance applications.

Surface Finishes and Tolerances

Precision parts require specific finishes and dimensional accuracy:

- Surface Roughness (Ra): Measured in micrometers (µm) or microinches (µin), different applications demand varying roughness levels, such as low Ra values for bearing surfaces.

- Tolerances: Tight tolerances (e.g., ±0.001mm) are crucial for high-performance applications and require meticulous control over machining conditions, including temperature and tool wear.

Secondary Processes

Availability of secondary processes enhances part quality and functionality:

- Heat Treatment: Modifies mechanical properties such as hardness and ductility.

- Plating and Anodizing: Adds protective layers or enhances aesthetics.

- Painting and Powder Coating: Provides durable finishes for corrosion resistance and visual appeal.

Software and Programming

CAD/CAM Software

Advanced CAD/CAM systems streamline the transition from design to production:

- CAD: Used to create precise 2D and 3D models.

- CAM: Generates toolpaths and CNC programs based on CAD designs.

- File Compatibility: Support for formats like STEP, IGES, and DXF ensures seamless data exchange.

Programming Expertise

Expert programmers optimize machining processes for efficiency and quality:

- Cycle Time Reduction: Minimize machining time while maintaining precision.

- Surface Finish Optimization: Achieve the desired roughness with effective toolpath strategies.

- Simulation Software: Prevent collisions and errors by verifying CNC programs before production.

Quality Control and Inspection

Inspection Equipment

High-quality inspection equipment ensures parts meet stringent specifications:

- CMMs: Provide precise dimensional verification for complex geometries.

- Optical Comparators: Inspect profiles and edges with high accuracy.

- Hand Tools: Calipers and micrometers are essential for on-the-fly measurements.

Quality Management System

A robust quality system ensures consistent results:

- Certifications: ISO 9001 and AS9100 signify adherence to industry standards.

- Statistical Process Control (SPC): Uses statistical methods to monitor and improve processes.

- Inspection Protocols: Regular checks throughout production reduce defects.

Engineering and Support

Engineering Expertise

A skilled engineering team adds value through:

- Design for Manufacturability (DFM): Suggesting design changes for efficient production without compromising functionality.

- Process Planning: Optimizing workflows to reduce costs and cycle times.

Communication and Project Management

Strong communication and project management ensure smooth operations:

- Responsiveness: Timely updates prevent misunderstandings and delays.

- Tracking Tools: Effective project management systems keep progress aligned with deadlines.

Evaluating the Plant in Practice

This section provides practical steps for assessing a CNC processing plant’s capabilities. Beyond reviewing their website or marketing materials, direct engagement and investigation ensure a comprehensive evaluation.

On-Site Visits

An on-site visit is one of the most effective ways to evaluate a CNC processing plant. It allows you to observe their operations, inspect equipment, and assess their overall environment. Key aspects to focus on include:

Cleanliness and Organization

- A clean, well-organized facility reflects a disciplined and efficient operation.

- Look for clear walkways, proper storage of tooling and materials, and a general sense of order.

- Cleanliness minimizes contamination risks and supports a safe working environment.

Equipment Condition

- Examine the condition of CNC machines and supporting equipment. Modern, well-maintained equipment is crucial for achieving precision and efficiency.

- Check for evidence of preventative maintenance, such as service logs and calibration records.

- Pay attention to:

- Cleanliness of machines (free from excessive chips or coolant spills).

- Proper guarding and safety mechanisms.

- Organization of tooling and workholding devices.

Manufacturing Processes

- Observe the flow of materials and workpieces through the facility. An efficient layout reduces bottlenecks and increases productivity.

- Evaluate whether processes are well-documented and operators are skilled, attentive, and following best practices.

Quality Control Procedures

- Inquire about quality control processes and observe inspection equipment like CMMs, optical comparators, and micrometers.

- Confirm the calibration schedules and certifications (e.g., ISO 9001, AS9100).

- Check if quality inspections are conducted at multiple production stages to ensure consistency.

Safety Practices

- Evaluate the plant’s adherence to safety protocols:

- Are employees wearing appropriate personal protective equipment (PPE)?

- Are safety procedures clearly posted and followed?

- A strong safety culture indicates professionalism and minimizes workplace hazards.

Communication and Interaction

- Observe how plant representatives communicate with you:

- Are they responsive, knowledgeable, and transparent?

- Do they provide clear and detailed answers to your questions?

- Effective communication reflects their commitment to customer service and professionalism.

Requesting Samples and Prototypes

Requesting samples or prototypes is an essential step to validate the plant’s technical capabilities. This provides tangible proof of their ability to meet your requirements.

Specify Your Requirements

- Provide detailed specifications for the sample, including:

- Material type and grade.

- Tolerances and surface finish requirements.

- Any additional criteria like heat treatment or secondary processes.

Evaluate the Samples

Carefully assess the samples to ensure they meet your expectations:

- Dimensional Accuracy: Use precise instruments like calipers or micrometers to verify tolerances.

- Surface Finish: Inspect for smoothness, texture, and adherence to Ra requirements.

- Material Properties: If necessary, conduct material testing to confirm the correct material and mechanical properties.

- Overall Quality: Check for defects, such as tool marks, scratches, or misalignments.

Prototype Development

- For new products or designs, request a prototype to:

- Test the design for functionality.

- Identify potential manufacturing issues before full-scale production.

- Ensure the plant can handle complex or custom requirements.

Checking References and Reviews

References and reviews provide valuable insights into the plant’s reliability and customer satisfaction.

Request References

- Ask the plant for a list of customer references. Contact these customers to inquire about:

- Quality of delivered products.

- Timeliness of delivery.

- Communication and responsiveness.

- Problem-solving capabilities and support for design changes.

Online Reviews and Case Studies

- Search for reviews on industry-specific forums, review sites, and platforms. Be aware of potential biases and look for consistent feedback patterns.

- Review case studies highlighting the plant’s success with similar projects, including technical challenges and implemented solutions.

Industry Associations and Certifications

- Check if the plant is a member of relevant industry associations. Membership often indicates a commitment to professional standards.

- Verify certifications like ISO 9001 or AS9100, which demonstrate adherence to rigorous quality management systems.

Supplier Audits

- For critical applications, consider conducting a formal supplier audit. This involves a detailed review of the plant’s:

- Quality management system.

- Manufacturing processes and workflows.

- Documentation and traceability systems.

Conclusion

Choosing the right CNC processing plant is a vital step in ensuring the success of your manufacturing projects. By thoroughly evaluating their technical capabilities, equipment, materials expertise, software, and quality control systems, you can identify a partner that aligns with your specific needs.

On-site visits, sample evaluations, and reference checks provide practical and tangible insights into a plant's operations and reliability. These steps help you verify claims, understand their workflows, and assess their commitment to quality and professionalism.

In today's competitive manufacturing landscape, selecting a CNC processing plant that combines technical expertise, advanced technology, and exceptional customer service is more important than ever. Investing time in this evaluation process will not only mitigate risks but also set the foundation for a long-term, successful partnership.

Ready to find the perfect CNC partner for your next project? Contact PROMACHINED today to discuss your manufacturing needs. Our expert team is here to provide tailored solutions, answer your questions, and deliver precision machining that exceeds your expectations. Let’s turn your ideas into reality!

FAQ:

What factors should be taken into consideration when selecting stock for CNC machining?

When selecting stock for CNC machining, consider the following factors:

- Material Type: Choose materials suited for your application, such as aluminum for lightweight parts, steel for strength, or titanium for high-performance needs.

- Dimensions: Ensure the stock size allows for efficient machining with minimal waste while accommodating part features.

- Tolerances: Select stock that meets initial flatness, roundness, or straightness tolerances to reduce additional processing.

- Machinability: Consider how easily the material can be machined. Materials like brass or aluminum are easier to machine, while titanium or Inconel require specialized tools.

- Surface Finish Requirements: Choose materials that align with your desired finish to minimize post-processing.

- Cost and Availability: Balance material costs with your project’s budget and lead time constraints.

What are the capabilities of CNC lathe?

CNC lathes are highly versatile and capable of performing various operations, including:

- Turning: Produces cylindrical parts by rotating the stock while a cutting tool removes material.

- Threading: Creates precise external and internal threads for fasteners or fittings.

- Drilling and Boring: Produces accurate holes along the axis or enlarges existing holes.

- Grooving: Adds grooves or recesses to cylindrical parts.

- Tapering: Produces tapered surfaces by adjusting tool angles.

- Parting Off: Cuts finished parts from the remaining stock.

- Live Tooling Operations: Modern CNC lathes can incorporate milling, slotting, or drilling perpendicular to the rotation axis, enhancing versatility.

These capabilities make CNC lathes ideal for manufacturing shafts, bushings, and precision cylindrical components across industries like automotive, aerospace, and medical.