Choosing the right CNC machining parts is crucial for achieving precision and quality in your projects. While it might seem straightforward at first—selecting the machine, material, and tools—it’s actually a detailed process that requires careful consideration of several factors. From ensuring the rigidity of your machine to selecting the right cutting tools and feedback systems, every component plays a vital role in the final outcome. It's like preparing a complex recipe—getting every detail right is key. So, how do you make sure you're choosing the best parts for your needs? Let’s break it down.

Choosing the Right CNC Machine: What’s Really Behind It?

Let’s talk about CNC machines for a moment. You’re not just picking a piece of machinery out of a catalog—oh no. It’s like buying a car; you’ve got to consider engine power, handling, and durability. When it comes to machines, we're talking about rigidity, thermal stability, and precision control systems. These aren’t just buzzwords. They’re the backbone of the machine's performance.

For example, a while back, I was working with a project that required high-speed machining of titanium. I went with a machine that seemed "good enough" on paper, but soon realized the lack of rigidity caused the machine to vibrate too much at higher speeds. Result? Dimensional inaccuracies that were hard to fix. After that, I made it a point to always prioritize rigidity—especially when dealing with tough materials like aerospace alloys.

And here's something a lot of people overlook: thermal stability. A machine that expands and contracts due to heat can throw off your precision, especially when you’re machining materials that are sensitive to temperature changes. For instance, machining titanium at high speeds can lead to heat buildup, and a machine that can’t regulate that heat is bound to give you issues. A lot of newer models come with built-in cooling systems that help maintain a consistent temperature, which is a huge plus.

So, What Do You Really Need from a CNC Machine?

| Factor | Why It Matters | How It Affects You |

|---|---|---|

| Rigidity | Prevents vibrations that can mess up precision | Essential for maintaining part accuracy |

| Thermal Stability | Controls temperature fluctuations | Prevents dimensional changes in materials like steel or titanium |

| Control Systems | Manages machine operation and precision | A reliable control system reduces operator error |

| Machine Bed Design | Keeps the workpiece stable | An unstable bed = vibrations and part distortion |

You’d be surprised how much of an impact these elements can have on your overall machining outcomes. It’s not just about machine size or brand—it’s about the synergy of these features coming together in harmony.

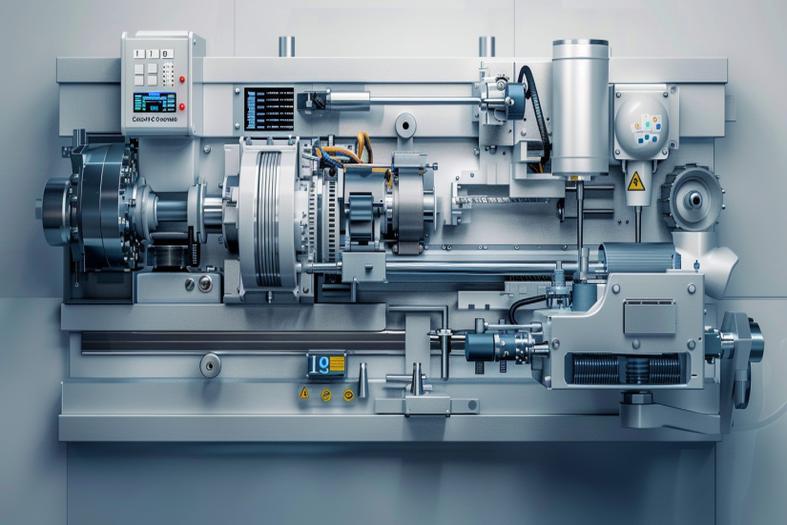

The Anatomy of CNC Machines: Key Parts You Should Know

Okay, let’s dive deeper into the CNC machine anatomy. Ever wonder what makes it all tick? Well, it’s more than just the controller and the motor—there’s a whole ecosystem at play. It’s like your body—every organ has a role. If one part fails, the whole system might collapse.

Let’s take the spindle, for example. It's the heart of your operation, the part that actually does the cutting. I remember once I was machining a batch of aluminum parts, and the spindle bearing started to wear down. Suddenly, the cut quality went to zero. It was like driving a car with wobbly wheels. Moral of the story: if your spindle isn’t in top shape, nothing else matters.

Then there’s the feedback system. This part is crucial for tracking the movements of the machine. If you don't have a feedback loop that’s spot on, well, your machine will lose its sense of direction, and you’ll end up with parts that are all over the place. Encoders and resolvers do the job of ensuring that the machine knows exactly where it is in space. Without that, you’re flying blind.

Lastly, don’t forget the tool holding system. A stable tool holder ensures that your tools are positioned precisely and consistently. If this isn’t right, you’ll be chasing errors for the entire production run.

| Component | Role in CNC Operation | Why It’s Important |

|---|---|---|

| Spindle | Drives the cutting tools | Determines the speed and quality of your cuts |

| Feedback System | Tracks the position of the machine | Keeps your operations precise and reliable |

| Tool Holding System | Holds the tools securely during machining | Guarantees consistent and accurate cuts |

It’s all about balance—when each of these components works in harmony, your machining results will be near-perfect.

The Cutting Edge: Advanced CNC Tools

When it comes to CNC machining, the tools you use can either make or break your project. We’re talking end mills, drill bits, reamers, taps—each tool has its specialty. But let’s take a moment to highlight laser cutting tools. These are revolutionary, especially for industries where precision matters down to the micron level.

A few months ago, we had a customer who needed ultra-fine cuts for a medical device. Traditional CNC machining wouldn’t have done the trick. Enter the laser cutter. These machines use focused laser beams to slice through material with incredible accuracy, leaving behind a smooth edge and reducing the need for post-processing. The result? Perfectly clean cuts in a fraction of the time.

A Look at Different CNC Tools: What They Do and Where They're Used

| Tool Type | Use | Materials | Applications |

|---|---|---|---|

| End Mills | Used for general milling operations | Steel, aluminum, plastics, and composites | Aerospace, automotive, medical components |

| Drill Bits | Designed for hole drilling | Stainless steel, aluminum, plastics | Electronics, automotive, heavy machinery |

| Laser Cutters | Ideal for precise, non-contact cutting | Stainless steel, titanium, composites | Aerospace, medical devices, high-precision prototypes |

| Reamers | Used for finishing holes to precise sizes | Steel, stainless steel, aluminum | Aerospace, automotive, and precision manufacturing |

| Tapping Tools | For internal threading | Steel, titanium, aluminum, plastics | Automotive, aerospace, heavy machinery |

The Future of CNC: A Peek Into Technological Trends

Let’s face it: CNC machining isn’t slowing down. If anything, it’s just getting started. I’ve been watching the rise of 5-axis CNC machines for a while now, and let me tell you—they’re game-changers. They can handle incredibly complex geometries that traditional 3-axis machines can only dream of.

And then there’s smart machining—machines integrated with sensors and AI that can monitor and adjust machining processes in real time. I’ve worked with some of these machines, and they can catch mistakes before they even happen. Imagine a world where the machine practically fixes its own errors! We’re not there yet, but it's coming.

Key Technological Innovations to Watch

- 5-Axis Machining – Complex geometries made easy.

- IoT Integration – Smart machines that adjust to their environment in real-time.

Wrapping Up: What’s the Best CNC Machining Strategy?

Choosing the right CNC machining parts isn’t just about ticking boxes. It's about making informed decisions based on the project needs, machine capabilities, and long-term goals. Trust me, after years in the field, I’ve learned the hard way that it’s about getting the small details right—from machine stability to the right tooling and coatings. It’s not always easy, but when everything aligns? It’s pure magic.