As a business owner navigating the complexities of international trade, you’ve probably faced challenges ensuring that your products meet strict quality standards. Whether it’s complying with ISO requirements, passing inspections, or managing audits, the stakes are high. A missed defect or non-compliance issue can result in shipment delays, financial losses, or even reputational damage.

But here’s the good news: a well-structured quality inspection system can eliminate these risks and give you the confidence to scale your business globally. Imagine having a seamless process that ensures your products meet every international compliance standard, keeping your customers satisfied and your operations running smoothly.

Quick Answer:

To build a quality inspection system for international compliance, follow these steps:

-

Understand International Standards: Familiarize yourself with key standards like ISO 9001, GMP, HACCP, and industry-specific regulations. Stay updated with changes in compliance requirements by monitoring regulatory bodies such as the FDA, EU authorities, and ISO.

-

Define Inspection Scope: Identify products or processes requiring inspection, determine critical quality attributes (CQAs), and establish acceptable quality levels (AQLs) and tolerances. Include the entire supply chain, from raw materials to finished goods.

-

Develop Inspection Procedures: Create clear, detailed procedures for inspections, specifying methods (visual, testing, or measurement), tools, and acceptance criteria. Use checklists and standardized forms for consistency.

-

Implement Inspection Processes: Set up inspection points at strategic stages like incoming materials, in-process checks, and final product inspections. Equip stations with necessary tools and train inspectors on standards and equipment use.

-

Manage and Analyze Data: Use software to collect and manage inspection data. Analyze trends to identify issues, track key performance indicators (KPIs), and guide continuous improvements.

-

Integrate Technology: Leverage automation technologies like Automated Visual Inspection (AVI), Coordinate Measuring Machines (CMM), and machine vision systems to improve speed, accuracy, and consistency.

-

Audit and Improve: Conduct regular internal audits, prepare for external audits, and use corrective and preventive actions (CAPA) to address non-conformances. Ensure management is actively involved in quality improvement initiatives.

Understanding International Compliance Standards

Introduction

Understanding and adhering to international compliance standards is not just a formality but a fundamental requirement for businesses involved in global trade. These standards ensure product quality, safety, and consumer trust while enabling businesses to access international markets and maintain competitiveness. This section provides a comprehensive overview of key standards, their types, and the regulatory bodies that oversee them.

Overview of Key International Quality Standards

A variety of international standards guide different industries and product categories. Below are some of the most widely recognized:

-

ISO 9001: Quality Management Systems

ISO 9001 is the most recognized international standard for quality management. It provides a framework for organizations to consistently deliver products and services that meet customer and regulatory requirements.- Key Focus: Customer satisfaction, leadership, employee engagement, continuous improvement, and evidence-based decision-making.

- Example: A manufacturing company uses ISO 9001 principles to streamline processes, reduce waste, and improve product quality.

-

GMP (Good Manufacturing Practice)

GMP guidelines are mandatory for industries like pharmaceuticals, medical devices, food, and cosmetics. They ensure that products are consistently produced and controlled according to quality standards.- Scope: Covers raw materials, equipment, premises, training, and staff hygiene.

- Regional Example: The FDA enforces cGMP (current GMP) in the U.S., while other regions have their own adaptations.

-

HACCP (Hazard Analysis and Critical Control Points)

HACCP is a preventive approach to food safety, focusing on controlling biological, chemical, and physical hazards.- Key Steps: Hazard analysis, identification of critical control points, and implementation of monitoring procedures.

- Industry Use: Ensures safe production and handling from raw materials to final consumption in food industries.

-

Industry-Specific Standards

Various industries follow unique standards tailored to their needs:- ISO 13485: Quality management for medical devices.

- IATF 16949: Quality management for automotive production.

- AS9100: Quality management for aerospace and defense industries.

Explanation of Different Types of Standards

International standards can be categorized into three primary types:

-

Product Standards

Define specific requirements for product attributes like performance, safety, dimensions, and materials.- Example: Standards for electrical safety (IEC 60364) or toy safety (EN 71).

-

Process Standards

Specify how processes should be executed to ensure quality and consistency.- Example: Welding standards (ISO 3834) or software development processes (ISO/IEC 12207).

-

Management System Standards

Provide frameworks for managing organizational activities systematically.- Example: ISO 9001 focuses on managing quality processes, while ISO 14001 addresses environmental management.

Discussion of Regulatory Bodies and Their Roles

Compliance is enforced and overseen by various regulatory bodies, each with distinct roles and responsibilities:

-

FDA (Food and Drug Administration)

Ensures the safety and efficacy of food, drugs, medical devices, and more in the U.S.- Key Role: Sets and enforces regulations like GMP, HACCP, and product labeling.

-

EU Regulations

The European Union enforces comprehensive regulations through directives and standards, such as CE marking and REACH (chemicals).- Example: The General Product Safety Directive ensures consumer protection across member states.

-

National Standards Organizations

Each country has its own standards organizations, often collaborating with international bodies like ISO:- ANSI (U.S.), BSI (U.K.), DIN (Germany).

Emphasis on the Importance of Staying Updated

International standards evolve with technological advancements, scientific research, and market needs. Businesses must stay informed to maintain compliance and competitiveness:

- Monitor Changes: Regularly review updates to relevant standards.

- Subscribe to Alerts: Sign up for notifications from organizations like ISO or ASTM.

- Participate in Forums: Join industry associations and workshops for updates.

- Consult Experts: Work with consultants or legal advisors specializing in compliance.

Example: ISO 9001 and Its Key Principles

ISO 9001 provides a structured approach to achieving consistent product quality and customer satisfaction. Its key principles include:

-

Customer Focus

Understanding customer needs and striving to exceed expectations. -

Leadership

Creating a unified vision and engaging employees in achieving quality objectives. -

Engagement of People

Empowering competent, motivated individuals to enhance organizational performance. -

Process Approach

Managing interrelated processes to achieve predictable results efficiently. -

Improvement

Continuously refining processes to enhance overall performance. -

Evidence-Based Decision Making

Using data analysis to drive decisions and improvements. -

Relationship Management

Building and maintaining strong supplier and stakeholder relationships to optimize organizational impact.

Defining Your Quality Inspection Scope

Importance of Defining the Scope

Defining the scope of your quality inspection is a critical first step in building an effective system. This involves identifying what needs to be inspected, determining the key aspects of quality, and setting acceptable levels of variation. A well-defined scope ensures that all critical areas are covered and quality issues are identified early.

Identifying the Products or Services That Need Inspection

Quality inspection should not be limited to the final product. It is essential to consider all stages where quality can be impacted:

- Raw Materials: Ensure the quality of incoming materials meets specifications.

- Components: Verify the integrity of intermediate parts.

- Work-in-Progress (WIP): Monitor quality during production.

- Finished Goods: Check for adherence to customer and regulatory requirements.

- Packaging and Labeling: Ensure proper presentation and accurate information.

For services, inspections may focus on delivery processes, customer interactions, and final outcomes.

Determining the Critical Quality Attributes (CQAs) for Each Product/Service

Critical Quality Attributes (CQAs) are the properties that must meet specified limits to ensure product performance and customer satisfaction. CQAs may include:

- Physical Attributes: Dimensions, weight, color, texture, and appearance.

- Chemical Properties: Composition, purity, pH, or viscosity.

- Biological Characteristics: Microbial contamination, sterility, or potency.

- Performance Metrics: Functionality, efficiency, reliability, or durability.

- Safety Standards: Toxicity, flammability, or electrical safety compliance.

Examples:

- Food Products: Safety (absence of pathogens), labeling accuracy, and ingredient quality.

- Electronics: Functional tests (signal quality), safety tests (electrical compliance), and durability assessments.

Defining Acceptable Quality Levels (AQLs) and Tolerances

AQLs represent the maximum acceptable number of defective items in a sample and are expressed as a percentage or number of defects per hundred units. Tolerances define the permissible variation in a dimension or characteristic:

- Statistical Standards: Use ANSI/ASQ Z1.4 or ISO 2859-1 for sampling guidance.

- Example: A metal component may have a dimensional tolerance of ±0.1 mm.

Considering the Entire Supply Chain

A holistic approach ensures quality issues are addressed early, reducing costs and risks:

- Incoming Materials: Inspect materials and components upon receipt.

- Production Processes: Monitor key stages to prevent defects.

- Finished Goods: Perform final inspections before shipment.

Establishing Inspection Procedures

Developing Clear and Detailed Inspection Procedures

Inspection procedures serve as a roadmap for consistent quality checks. Key elements include:

- Purpose and Scope: Define what the inspection aims to achieve.

- Step-by-Step Instructions: Provide detailed guidance for inspectors.

- Tools and Equipment: Specify required instruments and their usage.

- Acceptance Criteria: Clearly outline what constitutes a pass or fail.

- Non-Conformance Actions: Define steps to address defects.

Defining Inspection Methods

The methods used depend on the product type and CQAs. Common methods include:

- Visual Inspection: Identifying defects like scratches, dents, or discoloration with the naked eye or magnifying tools.

- Testing: Functional tests for performance, chemical analysis for composition, or stress tests for durability.

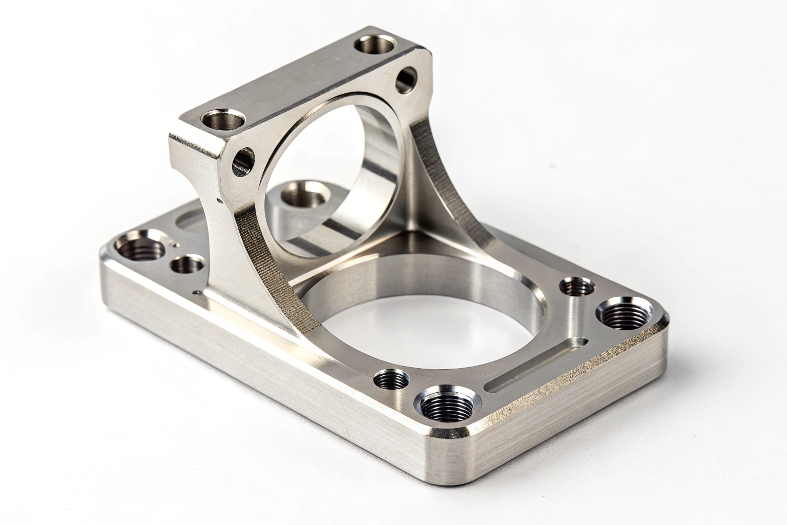

- Measurement: Using instruments such as calipers, micrometers, or coordinate measuring machines (CMM) to verify dimensions.

Creating Checklists and Inspection Forms

Checklists and forms standardize the inspection process and ensure thoroughness. They should include:

- List of CQAs: All attributes to be inspected.

- Space for Results: Record pass/fail status or measurements.

- Inspector Details: Signature, date, and any relevant notes.

Specifying Sampling Plans and Frequencies

Inspecting every unit is often impractical, so sampling plans are critical. Sampling strategies include:

- Single Sampling: Inspect a single batch of samples.

- Double Sampling: Take a second batch if the first is inconclusive.

- Multiple Sampling: Allow for additional batches as needed.

Frequency is determined by factors like production volume and defect history.

Documenting All Procedures for Traceability and Consistency

Maintaining comprehensive documentation ensures consistency and enables traceability:

- Procedure Manuals: Detailed instructions for all inspection activities.

- Inspection Records: Logs of all inspections performed.

- Auditable Data: Records that can be reviewed during audits or for continuous improvement.

Example: Visual Inspection of Finished Garments

A step-by-step procedure might include:

- Preparation: Ensure proper lighting and a clean workspace.

- Fabric Inspection: Look for stains, tears, or uneven weaving.

- Stitching Check: Examine seams for loose threads or skipped stitches.

- Sizing Measurement: Compare dimensions to size charts.

- Fastener Testing: Verify functionality of buttons or zippers.

- Label Check: Confirm accuracy and placement of all labels.

- Final Review: Inspect overall appearance for any defects.

- Documentation: Record results and note any issues.

Implementing Inspection Processes

Setting Up Inspection Points at Strategic Stages

Inspection points must be strategically placed throughout the production or delivery process to maximize defect detection and minimize costs related to rework or scrap. Key inspection stages include:

-

Incoming Material Inspection:

Inspect raw materials and components upon arrival to ensure they meet specifications. This step prevents defective materials from affecting downstream production.- Example: Inspect steel bars for dimensions, surface defects, and material certificates.

-

In-Process Inspection (WIP Inspection):

Inspect products at various stages during manufacturing. Early defect detection prevents the further processing of flawed items.- Example: Use gauges and micrometers during machining to verify dimensions.

-

Final Product Inspection:

Comprehensive inspection of finished goods before shipment to ensure compliance with customer and regulatory requirements.- Example: Use CMM for dimensional accuracy and visual checks for surface finish.

-

Pre-Shipment Inspection (PSI):

Independent inspection conducted before shipment to verify conformity with specifications, quantity, and packaging. -

Receiving Inspection (Customer Side):

Conducted by customers upon receiving goods to confirm compliance with agreed specifications.

Equipping Inspection Stations with Necessary Tools and Equipment

Properly equipping inspection stations is essential for effective inspections. Necessary tools include:

-

Measuring Instruments:

Calipers, micrometers, gauges, rulers, and CMMs for precision measurements. -

Testing Equipment:

Multimeters, tensile testing machines, and environmental test chambers for functionality and durability testing. -

Visual Inspection Aids:

Magnifying glasses, microscopes, and light boxes to detect surface defects. -

Software and Computers:

For data collection, analysis, and reporting. -

Specialized Tools:

Custom gauges, fixtures, or templates specific to the product being inspected.

Training Inspectors on Procedures, Standards, and Equipment Use

Proper training ensures inspectors perform accurate and consistent inspections. Key training areas include:

- Inspection Procedures: Step-by-step training on specific inspection methods.

- Standards Knowledge: Understanding applicable international and industry-specific standards.

- Equipment Usage: Hands-on training for proper use and maintenance of inspection tools.

- Defect Identification: Recognizing and categorizing defects based on severity.

- Documentation: Recording and reporting inspection results accurately.

Establishing a System for Recording and Documenting Inspection Results

Accurate documentation is essential for traceability, analysis, and continuous improvement. A robust system should include:

- Standardized Forms and Checklists: Uniform templates for consistent data collection.

- Data Entry and Storage: Digital systems (e.g., databases or QMS) for efficient storage and retrieval.

- Data Security: Measures to protect data from loss or unauthorized access.

- Traceability: Linking inspection results to specific products, batches, or production runs.

Example: Comprehensive Inspection Implementation

- Incoming Material Inspection: Inspect steel bars for dimensions, surface defects, and material certificates using calipers and visual checks.

- In-Process Inspection: Use micrometers during machining and conduct hardness tests after heat treatment.

- Final Product Inspection: Verify dimensional accuracy with a CMM, surface finish with roughness measurement equipment, and functionality using custom fixtures.

Data Management and Analysis

Importance of Accurate Data Collection and Recording

Accurate data is the foundation of effective quality management. Key practices include:

- Clear Data Entry Procedures: Standardize methods to ensure consistency.

- Inspector Training: Teach proper recording techniques.

- Regular Integrity Checks: Identify and correct errors in recorded data.

Using Software or Other Tools for Data Management

Tools for managing inspection data range from simple spreadsheets to advanced QMS software:

- Spreadsheets: Suitable for small-scale operations.

- Databases: Robust systems for storing and retrieving large datasets.

- Quality Management Software (QMS): Integrated tools for managing inspections, non-conformance reports, and corrective actions.

- Statistical Software: Advanced tools like Minitab or JMP for data analysis.

Analyzing Inspection Data to Identify Trends and Areas for Improvement

Inspection data analysis provides insights into process performance and improvement opportunities:

- Trend Analysis: Identify defect patterns over time.

- Pareto Analysis: Highlight the most frequent defects for targeted improvements.

- Root Cause Analysis: Investigate causes of defects using tools like fishbone diagrams.

Using Data to Track Key Performance Indicators (KPIs) Related to Quality

KPIs provide measurable benchmarks for monitoring quality performance:

- Defect Rate: Percentage of defective units.

- First Pass Yield (FPY): Percentage of units passing inspection the first time.

- Customer Returns: Number of returned products due to quality issues.

- Cost of Quality (COQ): Total cost of defects, including rework and customer dissatisfaction.

Example: Using Statistical Process Control (SPC)

- Control Charts: Use X-bar and R charts to monitor process variation.

- Data Plotting: Plot in-process measurements of critical dimensions.

- Control Limits: Identify deviations outside acceptable limits.

- Corrective Action: Investigate and resolve issues proactively to prevent defects.

Continuous Improvement and Auditing

Establishing a System for Corrective and Preventive Actions (CAPA)

A robust CAPA system is essential for addressing non-conformances and preventing their recurrence. The system should include:

- Identification of Non-Conformances: Clearly define how non-conformances are identified (e.g., through inspections, customer complaints, or audits).

- Root Cause Analysis: Use methodologies like the 5 Whys or fishbone diagrams to investigate the causes of non-conformances.

- Corrective Actions: Implement measures to eliminate the root cause of the issue.

- Preventive Actions: Take proactive steps to prevent potential non-conformances.

- Verification and Effectiveness Monitoring: Ensure that the implemented actions achieve the desired results.

- Documentation: Record the entire CAPA process for traceability and compliance.

Regularly Reviewing and Updating Inspection Procedures

Inspection procedures must evolve to remain relevant. Steps for regular updates include:

- Reviewing procedures for alignment with product changes, new standards, and technological advancements.

- Involving stakeholders like inspectors, engineers, and management in the review process.

- Incorporating feedback from audits and operational insights.

Conducting Internal Audits to Ensure Compliance

Internal audits systematically assess whether the quality system is effectively implemented and maintained. Best practices include:

- Planning and Scheduling: Develop an audit calendar covering all quality processes.

- Trained Auditors: Use independent and trained personnel to conduct audits.

- Follow-Up Actions: Address findings with CAPA and track progress.

Preparing for External Audits

External audits verify compliance with standards or regulations by third-party bodies or authorities. Preparation involves:

- Reviewing relevant standards and ensuring internal alignment.

- Conducting mock audits to identify potential gaps.

- Addressing non-conformances before the actual audit.

- Maintaining accurate and organized documentation.

Importance of Management Review and Commitment

Management’s role is pivotal in fostering a culture of quality improvement. Key actions include:

- Reviewing audit findings, CAPA results, and KPIs.

- Allocating necessary resources for quality initiatives.

- Actively participating in quality improvement programs.

Example: Implementing a Feedback Loop

- A defect (e.g., incorrect labeling) is identified during an inspection.

- The issue is logged into the CAPA system.

- Root cause analysis reveals outdated label templates.

- Corrective actions include updating the templates and retraining employees.

- Preventive measures involve reviewing all label templates for accuracy.

- Effectiveness is monitored through follow-up inspections.

Technology and Automation in Quality Inspection

Overview of Available Technologies

Modern tools are revolutionizing quality inspection:

- Automated Visual Inspection (AVI): Uses cameras and AI to detect surface defects in real-time.

- Coordinate Measuring Machines (CMMs): Provides high-precision dimensional checks.

- Robotics: Automates repetitive inspection tasks, increasing consistency.

- Laser Scanning: Captures detailed 3D product data for analysis.

- Non-Destructive Testing (NDT): Techniques like ultrasonic or radiographic testing evaluate materials without damage.

Benefits of Automation

Automation enhances quality inspection by:

- Increasing Speed: High throughput reduces production bottlenecks.

- Improving Accuracy: Eliminates human error in measurements.

- Ensuring Consistency: Standardizes inspection results across batches.

- Reducing Costs: Minimizes labor expenses and defect-related losses.

- Providing Real-Time Data: Enables immediate corrective actions.

Considerations for Implementing Automation

Challenges to address when adopting automation include:

- Cost: Evaluate ROI to justify initial investment.

- Complexity: Plan for system integration with existing processes.

- Maintenance: Establish regular upkeep and calibration schedules.

- Training: Equip employees with the skills to operate new technologies.

Example: Using Machine Vision for Defect Detection

- Cameras capture images of products on the production line.

- AI algorithms analyze the images to identify defects like scratches or misalignments.

- Defective items are flagged and removed automatically.

- Data on defects is recorded, providing insights for process optimization.

Cultural Aspects of Quality

Building a Culture of Quality Throughout the Organization

A strong quality culture ensures every employee values quality. Strategies include:

- Leadership Commitment: Top management must prioritize quality in policies and practices.

- Clear Communication: Share quality goals and progress with employees.

Emphasizing the Importance of Quality to All Employees

Quality awareness can be built by:

- Linking individual roles to overall quality objectives.

- Recognizing contributions to quality improvements.

Providing Ongoing Training and Development

Continuous learning is essential to keep employees updated on:

- New quality standards and regulations.

- Advances in inspection methods and tools.

Encouraging Employee Involvement in Quality Improvement

Empowering employees fosters innovation and ownership:

- Suggestion Programs: Offer platforms for employees to share ideas.

- Quality Circles: Create teams to tackle specific quality challenges.

Example: Quality Circles in Action

- A team identifies recurring defects in assembly processes.

- They brainstorm solutions and test process adjustments.

- Successful solutions are implemented organization-wide.

- Team efforts are recognized, motivating further contributions.

Conclusion

So, there you have it—a complete guide to building a robust quality inspection system for international compliance. We've covered everything from understanding key standards to implementing technology and fostering a culture of quality. I know it's a lot to take in, but trust me, once you have a solid system in place, the benefits will be worth the effort: fewer defects, happier customers, and smoother operations.

If you’re thinking about improving your quality processes or just starting to set up a system, I’m here to help. At PROMACHINED, we’ve built our business around precision and quality, and I’d love to share more tips or discuss how we can assist you.

Feel free to drop by our website at www.promachined.com to learn more about what we do or to reach out. Let’s connect and make your quality goals a reality!

Talk soon, my friend!

FAQ

What are the 4 types of quality inspection?

The four main types of quality inspection are:

-

Incoming Material Inspection (Pre-Production Inspection)

This inspection ensures the quality of raw materials, components, and purchased parts before they enter the manufacturing process. It involves verifying documentation (e.g., certificates of analysis), performing visual checks, and conducting tests to ensure compliance with specifications. -

In-Process Inspection (During-Production Inspection)

Conducted during various stages of production, this inspection identifies defects early, minimizing waste and preventing further processing of non-conforming items. It includes regular checks at critical operations or workstations. -

Final Inspection (Post-Production Inspection)

Performed after manufacturing is complete, this inspection verifies that finished goods meet all specified requirements before shipping or entering inventory. -

Pre-Shipment Inspection (PSI)

Conducted at the seller's premises or designated location before shipping, often by an independent third-party. PSI ensures conformity to specifications, quantity, packaging, and other agreed requirements, providing extra assurance, especially in international trade.

How to build a quality assurance program?

To build a quality assurance (QA) program, follow these steps:

-

Define Quality Goals

Establish SMART (Specific, Measurable, Achievable, Relevant, Time-bound) objectives aligned with customer needs, business strategies, and industry standards (e.g., ISO 9001). -

Develop Standard Operating Procedures (SOPs)

Create detailed instructions for key processes to ensure consistency, compliance, and ease of training. -

Implement Training Programs

Train employees on SOPs, quality standards, inspection techniques, and equipment usage to ensure competency in quality practices. -

Monitor and Inspect (Quality Control)

Conduct regular inspections, tests, and audits to identify deviations. Use tools like statistical process control (SPC) to analyze data and detect trends. -

Incorporate Feedback and Improve

Collect feedback from stakeholders and analyze audit findings to implement corrective and preventive actions (CAPA). Embrace continuous improvement to refine processes and enhance quality.

What are the components of a quality system inspection technique (QSIT)?

The FDA's QSIT focuses on evaluating four major subsystems of a quality management system:

-

Management Responsibility

Assesses leadership's role in quality, including setting policies, assigning responsibilities, allocating resources, and conducting management reviews. -

Design Controls

Evaluates the adequacy of product design processes to meet user needs and regulatory requirements. Includes design inputs, outputs, reviews, verification, validation, and transfer. -

Corrective and Preventive Actions (CAPA)

Focuses on processes for identifying, investigating, and resolving quality issues. This includes root cause analysis, implementing corrective actions, and verifying their effectiveness. -

Production and Process Controls

Reviews manufacturing controls like process validation, equipment maintenance, material management, and environmental conditions to ensure consistent product quality.

What is a QSIT inspection?

A QSIT (Quality System Inspection Technique) inspection is an FDA methodology for assessing compliance with the Quality System (QS) regulation (21 CFR Part 820). It evaluates how well a manufacturer’s quality system functions, focusing on key processes within four subsystems:

- Management Responsibility

- Design Controls

- Corrective and Preventive Actions (CAPA)

- Production and Process Controls

Unlike a checklist, QSIT uses a hierarchical, process-based approach. Inspectors assess interconnections between subsystems, selecting processes to audit based on risk and the firm's history. This systematic method ensures that the quality system is effectively implemented and meets regulatory requirements.