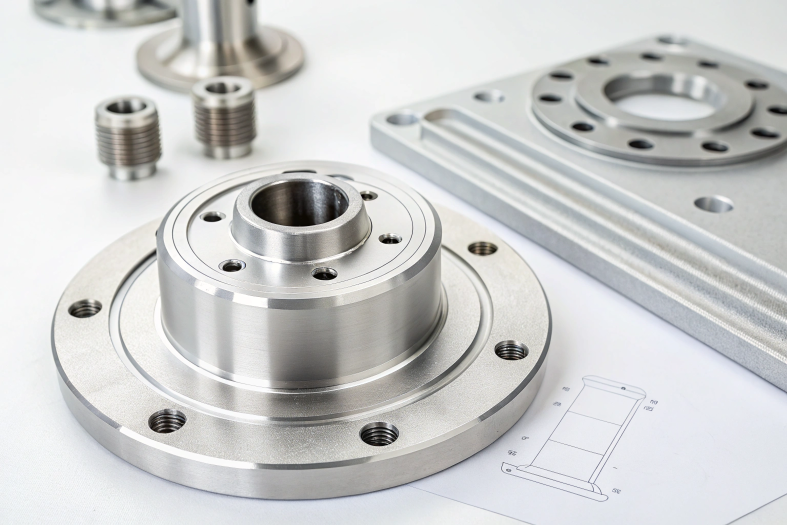

Let me share something with you as if we’re sitting down for coffee. Imagine you’ve got a crucial part for your project—a small piece that needs to fit perfectly to make the whole thing work. You need it to be precise, durable, and exactly to spec. This is where CNC machining steps in.

But here’s the thing: Precision isn’t magic—it’s the result of careful planning, consistent processes, and rigorous quality control. Whether it’s ensuring tolerances, achieving a flawless surface finish, or verifying dimensions down to micrometers, quality control is what turns CNC machining from good to exceptional.

Quick Answer:

Quality in CNC machining is ensured through precise planning, real-time monitoring, and rigorous inspections. It starts with Design for Manufacturability (DFM) to optimize geometries and material choices, followed by process planning for efficient machining sequences. During production, machine calibration, tool management, and in-process monitoring maintain accuracy. Finally, thorough inspections—First Article, in-process, and final—verify compliance with specifications, ensuring consistent, high-quality results.

Design and Planning Stage

This stage lays the groundwork for a successful CNC machining project. Careful consideration during design and planning significantly impacts the final product's quality, cost, and lead time.

Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is a critical engineering practice that focuses on optimizing product designs to facilitate efficient and cost-effective manufacturing processes. In CNC machining, DFM principles ensure that parts can be produced with high quality while minimizing machining time, material waste, and potential errors.

-

Simple geometries and avoiding complex shapes:

Simplified geometries reduce manufacturing complexity and cost. Complex designs often require specialized tooling, multiple setups, and longer machining times. For example:- Sharp corners and intricate internal features should be avoided where possible.

- Instead of sharp internal corners, adding radii improves tool movement and reduces machining stress.

- Example: A radius in internal corners strengthens the part while reducing machining time.

-

Standardized tolerances and avoiding overly tight tolerances:

Specifying unnecessarily tight tolerances increases machining time and costs. Tight tolerances require more precise machining operations and specialized tools. For instance:- Instead of a tolerance of ±0.0005", using ±0.002" might suffice for non-critical dimensions.

- This approach not only saves costs but also reduces rejection rates during inspection.

-

Appropriate radii and fillets:

Incorporating radii on internal corners (fillets) and external edges (rounds) prevents stress concentrations, strengthens parts, and simplifies machining. Standard sizes reduce the need for tool changes.- Example: A 2mm fillet in an aluminum part enhances durability while easing cutting tool paths.

-

Avoiding thin walls and deep cavities:

Thin walls (<1mm) are prone to vibration, deflection, and poor surface finishes. Deep cavities often require slender tools, increasing the risk of vibration and damage. Consider design alternatives:- Add support ribs or gussets to reinforce thin walls.

- Use multiple components joined post-machining if deep cavities are unavoidable.

- Example: Splitting a part with a deep cavity into two joinable pieces can improve manufacturability.

Material Selection

Selecting the appropriate material is fundamental to achieving the desired performance and quality in CNC machined parts. The material's properties directly influence the machining process, the part's functionality, and its overall cost.

Key factors include:

-

Material properties:

Materials with excellent machinability (e.g., aluminum alloys) offer smoother finishes and faster production times. Harder materials like stainless steel or titanium require specialized tooling and slower cutting speeds.- Example: Aluminum 6061 is preferred for prototypes due to its machinability, while stainless steel 304 is ideal for corrosion-resistant applications.

-

Application requirements:

Material selection should align with the part's functional needs, including resistance to temperature, wear, and corrosion.- Example: A part exposed to high heat might require Inconel, while components in marine environments may use brass or stainless steel for corrosion resistance.

-

Cost considerations:

While high-performance materials like titanium provide excellent properties, they can be cost-prohibitive. Balancing performance with budget constraints ensures an optimal choice.- Example: For non-critical applications, choosing a lower-cost grade of aluminum might achieve adequate performance while reducing expenses.

Process Planning

Thorough process planning is essential for ensuring efficient and precise machining. This stage involves defining the optimal sequence of operations, selecting appropriate cutting tools and parameters, determining workholding methods, and generating the CNC program.

Key aspects include:

-

Optimal machining sequence:

Planning machining steps in the correct order minimizes setups and tool changes, saving time and ensuring consistent quality.- Example: Perform roughing operations to remove excess material before fine finishing to achieve precision without tool wear.

-

Cutting tools and parameters:

Selecting the right tools and machining parameters ensures surface quality, dimensional accuracy, and tool longevity.- High-speed cutting tools with coatings like TiAlN are ideal for machining hard materials.

- Example: When cutting aluminum, a spindle speed of 15,000 RPM and a feed rate of 0.3 mm/rev maximize efficiency.

-

Workholding methods:

Proper workholding secures the part during machining, preventing movement or vibration that could lead to inaccuracies.- Example: Complex geometries may require custom fixtures for secure positioning, while simpler parts can use standard vises or clamps.

-

Programming with G-code:

G-code is the language that controls CNC machines, specifying toolpaths and machining operations. Accurate programming prevents collisions, reduces errors, and optimizes machining performance.- CAM software like Fusion 360 or Mastercam generates optimized G-code from CAD models, simulating the machining process to preemptively address potential issues.

- Example: A CAM-generated toolpath minimizes unnecessary tool movements, ensuring efficient machining.

Machining Stage

This stage is where the actual material removal takes place. The quality of the final product heavily relies on the precision and control exercised during this phase. Proper machine setup, real-time monitoring, and effective tool management are key to achieving accurate and consistent results.

Machine Setup and Calibration

Proper machine setup and calibration are paramount for achieving accurate and consistent results. These procedures ensure the machine operates within its specified tolerances and that the workpiece is positioned correctly.

-

Machine alignment and rigidity:

- Alignment ensures the geometric relationship between the machine's components, such as the spindle, axes, and table, is maintained. Misalignment can result in dimensional inaccuracies and poor surface finishes.

- Rigidity refers to the machine's ability to resist deflection under load. A lack of rigidity can cause vibrations and chatter during machining, negatively impacting part quality.

- Regular checks using precision tools like dial indicators or laser alignment systems help maintain alignment and rigidity.

- Example: A machine with poor rigidity may cause chatter marks on a surface, while a well-aligned machine produces smooth finishes.

-

Calibration of axes and spindles:

- Axis calibration ensures the machine moves the exact distance commanded, while spindle calibration ensures the spindle rotates at the correct speed and alignment.

- Tools like laser interferometers and ball bars are commonly used for precise calibration.

- Regular calibration compensates for wear and tear over time, preserving accuracy.

- Example: A calibrated spindle with minimal runout ensures consistent hole diameters in drilling operations.

-

Workholding fixtures:

- Proper workholding securely stabilizes the workpiece, preventing movement or vibrations during machining.

- Fixtures must withstand cutting forces without deforming the workpiece and should allow easy loading and unloading.

- Examples include vises for prismatic parts, chucks for cylindrical components, and custom fixtures for irregular geometries.

- Tip: Vacuum chucks are ideal for thin, flat parts, while modular fixtures are suitable for complex setups.

In-Process Monitoring and Control

Real-time monitoring and control are essential for maintaining machining accuracy, detecting deviations, and preventing defects. This proactive approach minimizes scrap and enhances overall process efficiency.

-

Visual inspection:

- Experienced machinists use visual inspection to identify issues such as tool wear, chip buildup, or coolant problems.

- This method remains effective for assessing surface finish and detecting anomalies during machining.

- Example: Chips that appear discolored or irregular in shape may signal excessive heat or incorrect cutting parameters.

-

Sensors:

- Sensors provide real-time data on cutting forces, vibrations, temperatures, and acoustic emissions.

- Force sensors detect excessive cutting forces, which could indicate dull tools or incorrect feed rates.

- Vibration sensors help identify chatter, which may affect surface finish and tool life.

- Example: Temperature sensors on the spindle can prevent overheating, extending both tool and machine life.

-

Adaptive control systems:

- These systems use sensor data to automatically adjust machining parameters, such as spindle speed or feed rate, in response to changing conditions.

- This real-time adjustment prevents tool breakage, enhances part quality, and optimizes efficiency.

- Example: If excessive vibrations are detected, the system may reduce the cutting speed to stabilize the process.

Tool Management

Effective tool management maximizes machining efficiency, minimizes downtime, and ensures consistent part quality. Cutting tools directly influence surface finish, dimensional accuracy, and material removal rates.

-

Selecting the right tools:

- Tool selection depends on material type, machining operation, and desired finish.

- Factors to consider include tool material (e.g., carbide for hard materials, HSS for softer materials), geometry (e.g., flute count, cutting edge angle), and coatings (e.g., TiAlN for heat resistance).

- Example: A 4-flute carbide end mill works well for finishing steel, while a 2-flute tool is better for aluminum chip evacuation.

-

Maintaining tool sharpness:

- Sharp tools produce better surface finishes and require less cutting force, reducing heat and wear.

- Dull tools can lead to chatter, excessive heat generation, and dimensional inaccuracies.

- Regular inspection, regrinding, or replacement ensures optimal tool performance.

- Example: Tool wear monitoring systems can predict when tools need replacement, minimizing unexpected downtime.

-

Tool presetters:

- Tool presetters measure and set tool parameters, such as length and diameter, with high precision before loading into the CNC machine.

- Accurate measurements reduce setup time and prevent collisions.

- Example: A tool presetter ensures that a drill bit’s tip is positioned precisely for consistent hole depths across multiple parts.

Inspection and Measurement Stage

This stage is crucial for verifying that the machined parts meet the required specifications and quality standards. Thorough inspection and measurement throughout the production process, from the first article to the final product, ensure customer satisfaction and minimize the risk of defects.

First Article Inspection (FAI)

First Article Inspection (FAI) is a comprehensive inspection of the first part produced in a production run. Its purpose is to verify that the manufacturing process, including machining parameters, tooling, and setups, is capable of producing parts that meet all design specifications.

Key aspects:

-

Inspecting the initial part:

- The first article undergoes a thorough inspection to ensure all critical dimensions, tolerances, and surface finishes meet design specifications.

- A combination of manual measuring instruments (e.g., calipers, micrometers) and advanced metrology equipment (e.g., Coordinate Measuring Machines) is used.

- FAI confirms the accuracy of the CNC program, tooling setup, and machine operation.

- Example: For an aerospace component, FAI might include inspecting hole diameters, thread pitches, and surface flatness to ensure compliance with stringent industry standards.

-

Documenting results:

- A detailed FAI report documents all inspection results, including measurements, tolerances, and any deviations from specifications.

- The report serves as a baseline for subsequent production and a reference for quality control.

- Industries like aerospace often use standardized formats such as AS9102 for FAI documentation.

- Example: An FAI report for a turbine blade might include CMM data, material certifications, and photographs of inspected features.

In-Process Inspection

In-process inspection involves checking parts during the machining process to identify and correct deviations early. This approach minimizes waste, prevents defects, and ensures process consistency.

Methods:

-

Measuring instruments:

- Tools like calipers, micrometers, gauges, and dial indicators provide quick checks of dimensions and tolerances during machining.

- These tools are especially useful for verifying critical dimensions immediately after specific machining operations.

- Example: After drilling, a machinist uses a caliper to confirm the bore diameter is within tolerance.

-

Coordinate Measuring Machines (CMMs):

- CMMs measure dimensions and geometries with high precision, especially for parts with complex shapes or tight tolerances.

- These machines use probes to touch points on a part’s surface, calculating coordinates to verify compliance with design specifications.

- Example: A CMM program might inspect the contours of a medical device, ensuring it matches the CAD model within micrometer-level accuracy.

-

Vision systems:

- Vision systems use cameras and image processing software to automate inspection tasks like dimensional measurement, surface defect detection, and part orientation verification.

- Ideal for high-volume production, they improve efficiency and consistency.

- Example: In automotive manufacturing, vision systems can detect surface scratches on engine components in seconds, ensuring cosmetic and functional standards are met.

Final Inspection

Final inspection is the last check performed on finished parts before shipment to the customer. It ensures all requirements are met and the parts are ready for use.

Techniques:

-

Dimensional measurements:

- Advanced metrology equipment like CMMs, laser scanners, and optical comparators are used to confirm that all dimensions and tolerances meet specifications.

- Example: A laser scanner might create a 3D model of a machined part, comparing it to the CAD file to detect deviations.

-

Surface finish evaluation:

- Surface finishes are assessed to meet aesthetic and functional standards. Profilometers or roughness testers evaluate surface roughness, while visual inspection checks for cosmetic defects.

- Example: A polished medical implant is inspected to ensure a smooth finish that minimizes bacterial adhesion.

-

Documenting inspection results:

- Final inspection results are compiled into a comprehensive report, providing traceability and assurance for customers.

- Reports may include dimensional data, surface finish evaluations, and SPC data to demonstrate process capability.

- Example: A final inspection report for a high-precision aerospace part might include CMM measurements, material certificates, and photographs of inspected features.

Quality Management Systems

Implementing a robust quality management system (QMS) is essential for consistently producing high-quality CNC machined parts. A well-defined QMS provides a framework for managing processes, ensuring customer satisfaction, and driving continuous improvement.

ISO 9001 Certification

ISO 9001 is an internationally recognized standard for quality management systems. Achieving ISO 9001 certification demonstrates a company’s commitment to meeting customer requirements and continually improving its processes.

Key requirements include:

-

Defined processes:

- ISO 9001 emphasizes the importance of documented and controlled processes. Key activities, from design and planning to manufacturing and inspection, must be defined, documented, and followed consistently.

- This ensures repeatable quality and reduces the risk of errors. Procedures, work instructions, and quality records are essential components of a documented QMS.

- Example: A CNC shop might create a step-by-step work instruction for tool calibration, ensuring that every operator follows the same procedure for consistency.

-

Customer focus:

- A central principle of ISO 9001 is customer focus. Companies must understand and meet customer needs, including product specifications, service quality, and delivery timelines.

- Feedback from customers is actively sought and used to drive improvement.

- Example: Customer surveys and regular review meetings with key clients help identify areas for improvement in service and product quality.

Continuous Improvement

Continuous improvement is an ongoing effort to enhance products, services, or processes. In CNC machining, it focuses on optimizing machining parameters, reducing scrap rates, improving efficiency, and enhancing overall quality.

Key methods include:

-

Root cause analysis:

- This systematic approach identifies the underlying causes of problems or defects. By addressing the root cause, recurring issues can be prevented, improving overall quality.

- Techniques like the "5 Whys" and fishbone diagrams are commonly used.

- Example: If machined parts frequently fail tolerance checks, root cause analysis might reveal misaligned fixtures as the culprit.

-

Corrective and Preventive Actions (CAPA):

- CAPA involves addressing quality issues and preventing their recurrence.

- Corrective actions resolve existing problems, while preventive actions mitigate potential issues.

- Example: If a batch of parts is rejected due to tool wear, a corrective action might include re-machining defective parts, while a preventive action could involve introducing more frequent tool inspections.

-

Statistical Process Control (SPC):

- SPC uses statistical techniques to monitor and control processes. By collecting and analyzing data on key parameters, deviations can be detected early, preventing defects.

- Example: Control charts can track cutting force trends over time, identifying when tools need to be replaced before they fail.

Tools and Technologies for Quality Assurance

Quality assurance in CNC machining relies on a combination of traditional measuring instruments and advanced technologies to verify compliance with specifications and ensure consistent quality.

Precision Measuring Instruments

-

Examples:

- Calipers and micrometers: For measuring linear dimensions, diameters, and depths with high accuracy.

- Height gauges: To measure vertical dimensions relative to a flat surface.

- Dial indicators: To check alignment, flatness, and concentricity.

- Surface roughness testers: To evaluate the finish of machined surfaces.

-

Purpose:

- These instruments ensure dimensional accuracy and consistency by verifying part dimensions against design specifications.

- Example: A micrometer with a resolution of 0.001mm can measure a shaft’s diameter to ensure it fits precisely into a bearing assembly.

Software for Simulation and Verification

Advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software play a crucial role in quality assurance by simulating the machining process and verifying designs.

-

Benefits:

- Simulation helps detect potential issues like tool collisions, interference with workholding fixtures, or excessive material removal.

- Optimized machining parameters improve efficiency, surface finish, and tool life, saving time and reducing costs.

-

Examples:

- Mastercam: Simulates toolpaths and generates efficient G-code for CNC machines.

- SolidWorks: Combines design and simulation features to ensure manufacturability.

- Vericut: Specializes in G-code verification to detect toolpath errors and collisions.

-

Purpose:

- Simulation and verification reduce trial-and-error machining, ensuring parts meet specifications without wasting materials.

- Example: A simulation might reveal that a toolpath results in excessive cutting force, prompting adjustments to feed rates.

Statistical Process Control (SPC)

SPC is a data-driven approach to monitoring and controlling CNC machining processes. By analyzing key process data, it ensures stability and identifies potential issues before they result in defects.

-

Role:

- Tracks parameters such as part dimensions, surface finish, and cutting forces to maintain process consistency.

- Example: An SPC chart showing increasing variability in hole diameters might indicate tool wear, prompting a timely replacement.

-

Techniques:

- Control charts: Visualize process stability and highlight deviations.

- Histograms: Display the distribution of measured values to identify patterns or anomalies.

- Process capability studies: Assess whether a process consistently meets specified tolerances.

-

Purpose:

- Ensures processes operate within acceptable limits, reducing scrap and rework.

- Example: A control chart for cutting speeds might show when adjustments are needed to maintain optimal machining conditions.

Common Challenges in Quality Assurance

Maintaining consistent quality in CNC machining is not without its challenges. Several factors can introduce variability and affect the final product's quality. Understanding these challenges is crucial for implementing effective quality control measures.

Variability in Raw Materials

Raw materials, even when sourced from the same supplier and meeting identical specifications, can exhibit variations in their properties. These differences can significantly impact machinability and lead to inconsistencies in the final product.

-

Material inconsistencies:

- Variations in hardness, chemical composition, microstructure, and internal stresses can result in inconsistent cutting forces, tool wear, surface finishes, and dimensional accuracy.

- Example: Harder material sections can cause increased tool wear, leading to deviations in dimensions or surface quality. Internal stresses released during machining may cause part distortion.

-

Impact on machining outcomes:

- Materials with inconsistent properties may result in some parts being easier to machine than others, leading to variability in the end product.

-

Solutions:

- Implement rigorous incoming material inspection using hardness testers, spectrometers, and ultrasonic testing.

- Ensure material certifications and traceability to verify consistency and quality.

- Example: In aerospace applications, certified materials are inspected for composition and microstructure to meet stringent requirements.

Machine Wear

CNC machines, like any mechanical equipment, are subject to wear and tear over time. This wear affects the precision and performance of critical components, leading to deviations in machining accuracy.

-

Common wear issues:

- Spindle bearings: Wear can cause runout, impacting the accuracy of circular features.

- Guideways and ball screws: Degradation can lead to backlash, inaccuracies in linear movements, and reduced rigidity.

- Vibrations and alignment issues: Machine wear may introduce unwanted vibrations, reducing surface finish quality and part accuracy.

-

Impact on production:

- Machine wear can compromise the dimensional integrity of parts and increase production downtime for repairs.

- Example: A worn spindle bearing may result in inconsistent bore diameters, necessitating rework or scrapping of parts.

-

Solutions:

- Regular maintenance schedules including lubrication, alignment checks, and component replacements.

- Predictive maintenance strategies using sensor data to forecast when maintenance is required.

- Example: Vibration analysis or thermal imaging can detect early signs of wear, allowing timely intervention before production quality is affected.

Human Error

Despite advancements in automation, human involvement remains integral to CNC machining. Errors at any stage, from setup to inspection, can result in defects or inefficiencies.

-

Setup errors:

- Incorrect orientation, improper clamping, or misaligned fixtures can lead to inaccurate machining.

- Example: A misaligned workpiece may cause features to be machined off-center, resulting in scrap parts.

-

Tool setup mistakes:

- Errors in tool length, diameter settings, or incorrect tool selection can lead to collisions, improper cutting depths, or toolpath deviations.

-

Programming errors:

- Mistakes in CNC programming may result in incorrect toolpaths, feed rates, or spindle speeds.

- Example: An overlooked decimal in the feed rate may cause tools to plunge too quickly, leading to breakage.

-

Inspection inaccuracies:

- Misreading measuring instruments or overlooking defects during visual checks can result in non-conforming parts being accepted.

-

Solutions:

- Provide comprehensive training for personnel to improve skill levels and awareness of quality standards.

- Develop clear work instructions and error-proofing techniques (poka-yoke) to minimize the potential for mistakes.

- Example: Automation of repetitive tasks, such as tool changes and part loading/unloading, reduces reliance on human intervention and minimizes error potential.

Addressing Challenges

These challenges underscore the importance of a comprehensive approach to quality assurance in CNC machining. Key strategies include:

- Rigorous material selection and inspection: Ensures consistent input quality and minimizes material-related variability.

- Regular machine maintenance and calibration: Maintains equipment accuracy and reliability over time.

- Thorough training of personnel: Builds expertise and minimizes human error.

- Robust quality control procedures: Standardizes processes and incorporates automated systems to reduce variability.

Conclusion

And there you have it—a complete guide to how quality is ensured in CNC machining, from the very first design considerations to the final inspection. Maintaining high standards in CNC machining is no easy feat, but with proper planning, precise machining, robust quality control systems, and a commitment to continuous improvement, it’s absolutely achievable.

If you’re as passionate about precision manufacturing as I am or have any specific machining needs, feel free to explore more on www.promachined.com. Whether it’s a small project or a large-scale production, let’s chat and see how we can collaborate to create something exceptional.

Thanks for sticking around, and if you’ve got questions or just want to talk shop, don’t hesitate to reach out. Until next time, happy machining!

FAQ:

What is the role of CNC in quality control?

CNC (Computer Numerical Control) is fundamental in ensuring high-quality manufacturing by producing parts with precise and repeatable accuracy. While CNC itself is not "in quality control," it enables quality control by adhering closely to design specifications, including dimensions, tolerances, and surface finishes. Quality assurance in CNC machining integrates processes like First Article Inspection (FAI), in-process monitoring, and final inspection. Together, these ensure that every machined part meets the required standards, minimizing defects and maximizing reliability.

How is CNC machine accuracy checked?

Checking CNC machine accuracy involves several systematic methods to ensure consistent and precise machining:

-

Calibration Tests:

- Use laser interferometers to measure linear and positional accuracy and ball bars to evaluate circular interpolation and geometric errors.

- These high-precision tools identify misalignments or deviations in machine performance.

-

Test Cuts (or Test Pieces):

- Machining a test piece with predefined dimensions helps verify the machine's accuracy.

- Instruments like Coordinate Measuring Machines (CMMs) and micrometers measure the test piece against specifications, revealing deviations.

-

Alignment Checks:

- Regularly verify the alignment of axes, spindle runout, and table flatness using tools like dial indicators, precision squares, and levels.

- Alignment ensures consistent and accurate cuts.

-

Maintenance Practices:

- Regular and predictive maintenance, such as lubricating components, replacing worn parts, and inspecting ball screws or guideways, helps preserve accuracy over time.

- Example: Vibration analysis can detect early signs of wear, allowing timely interventions.

What are the key principles of CNC machining?

The key principles of CNC machining are:

-

Automation:

CNC machines follow pre-programmed instructions (G-code), automating operations to minimize manual intervention and reduce human error. -

Precision and Repeatability:

CNC machining ensures high precision and repeatability, producing identical parts with tight tolerances across multiple runs. This consistency is critical in industries like aerospace and medical devices. -

Flexibility and Versatility:

CNC machines can handle a variety of tasks, including milling, turning, drilling, and grinding. They can switch between operations quickly by loading new programs and tools, making them suitable for both small-batch and large-scale production.

What constitutes machining quality?

Machining quality determines whether a part meets its intended purpose, balancing precision, functionality, and appearance. Key factors include:

-

Dimensional Accuracy and Tolerances:

- Parts must conform to design specifications with tight tolerances to ensure proper fit and functionality.

-

Surface Finish:

- Surface texture and smoothness, measured by parameters like Ra (average roughness), affect both the aesthetics and functionality of the part.

-

Material Integrity and Properties:

- Machining should preserve material properties without introducing defects like cracks, warping, or residual stresses.

-

Form and Geometry:

- Features like flatness, roundness, and profile accuracy must meet design requirements to ensure compatibility and performance.

Achieving high machining quality relies on proper machine setup, optimized tooling and parameters, effective workholding, and rigorous quality control throughout the manufacturing process.