In modern manufacturing, CNC machining is renowned for its exceptional precision. However, for many businesses and engineers, understanding how CNC machining achieves such high levels of accuracy remains a key question. To stay competitive, it's essential to grasp the underlying principles and advantages of CNC technology, particularly when it comes to precision control. By integrating advanced technologies, automation, and meticulous operations, CNC machining delivers unparalleled accuracy even in the most complex tasks.

1.Direct Answer:

CNC machining achieves high precision by using computer-controlled machines that precisely follow design specifications. Automated systems, sensors, and feedback loops ensure minimal tolerances, resulting in extremely accurate machining outcomes.

2. Fundamentals of CNC Technology

The ability of CNC machining to produce high-precision parts is rooted in its core technologies, from computer-controlled programming to sophisticated motion control systems.

CNC Programming:

CNC machining starts with programming that defines the tool paths and machining operations. Programs are written using G-codes and M-codes that specify every aspect of the operation—from movement to speed, tool changes, and coolant use. Precision programming ensures that the machine will carry out tasks with tight tolerances and exact repeatability.

- Advanced G-codes and M-codes: For example, a G-code like

G17can select the XY plane for tool paths, whileM06might trigger a tool change. The accuracy of these commands directly influences the machining result. - CNC Simulation Software: Modern CAM (Computer-Aided Manufacturing) software not only generates tool paths but also simulates the entire machining process. This helps identify potential issues before they occur, such as collisions, tool deflection, or overheating, which could lead to errors.

Numerical Control Systems:

At the core of CNC machining is the numerical control system, which is responsible for translating the G-code instructions into physical machine movements. It uses feedback loops and control algorithms to ensure the precision of every cut.

-

Real-Time Control Systems: The CNC system continuously adjusts the position of the tool and workpiece in real-time. These systems employ complex algorithms like PID (Proportional Integral Derivative) controllers to minimize errors in tool positioning and compensate for disturbances such as mechanical backlash or thermal drift.

-

Error Compensation Techniques: Advanced CNC systems often integrate error compensation algorithms that adjust the machine’s movements to account for mechanical imperfections like backlash, misalignment, or tool wear. This ensures that even minor errors don’t accumulate during the machining process.

3. Precision Equipment and Tools

The equipment and tooling used in CNC machining play a crucial role in ensuring parts are machined to high tolerances. The combination of advanced hardware and precise tools allows manufacturers to push the limits of machining precision.

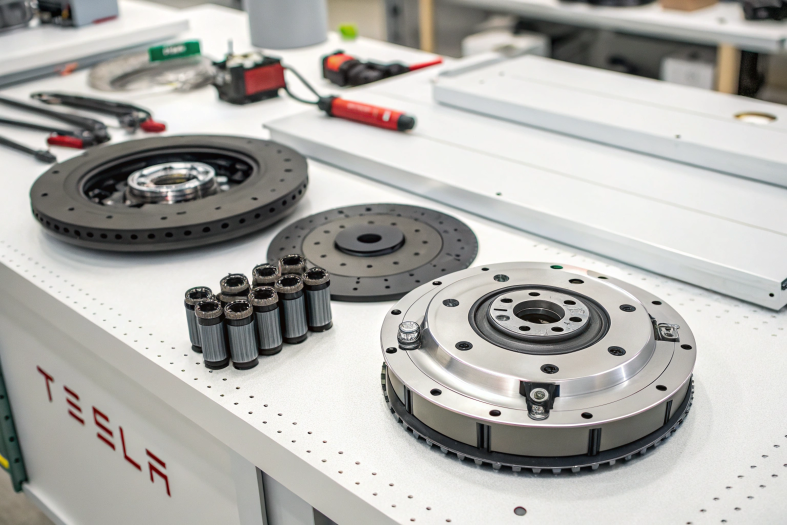

High-precision CNC Machines:

Modern CNC machines are built with the utmost precision in mind. The components, from ball screws to guide rails, are designed to minimize errors, wear, and thermal distortion. High-end CNC machines, such as multi-axis milling centers and turning centers, offer improved rigidity and better control of the cutting process.

-

Thermal Stability: The materials used to construct high-precision CNC machines are selected for their low coefficient of thermal expansion (CTE). This ensures that machines remain dimensionally stable even when exposed to fluctuating temperatures, preventing thermal distortion and maintaining part accuracy.

-

Linear and Rotary Encoders: High-precision CNC machines are often equipped with linear and rotary encoders that provide continuous feedback on the position of machine components. This feedback allows for sub-micron accuracy in the movements of the machine’s axes.

Tool Selection:

The selection of the right cutting tool is critical to achieving precision. Factors such as the tool’s geometry, material, and coating directly affect the precision of the machining process.

-

Tool Geometry: Tools with sharper cutting edges and optimized geometries reduce cutting forces, minimize heat generation, and improve surface finishes. For example, tools with a low rake angle are commonly used in hard materials to reduce the risk of tool chatter.

-

High-performance Coatings: Cutting tools are often coated with advanced materials like TiAlN (Titanium Aluminum Nitride), which increases hardness and heat resistance. These coatings reduce friction during cutting, leading to longer tool life and improved dimensional accuracy.

Tool Path Optimization:

Tool path optimization is a key aspect of high-precision machining. With the aid of advanced CAM software, manufacturers can generate tool paths that minimize deviations and ensure consistent machining accuracy throughout the entire process.

-

Optimization Algorithms: CAM software uses optimization algorithms to reduce the tool’s movement across non-cutting areas, decreasing machining time and reducing wear on both the tool and workpiece. Optimized tool paths also minimize tool deflection, which can distort the part’s dimensions.

-

Adaptive Machining: Adaptive machining refers to adjusting the cutting conditions, tool paths, or feed rates in real-time based on sensor feedback or machine performance, ensuring that the machining process remains within specified tolerances throughout.

4. The Impact of Material on Precision

Material properties play a significant role in determining how precisely a workpiece can be machined. The hardness, thermal conductivity, and homogeneity of the material all affect how it responds to the cutting forces.

Material Selection:

Choosing the right material for machining is fundamental for achieving precision. The material's hardness, stability, and machinability dictate how easily it can be shaped into the desired form while maintaining tight tolerances.

-

Hardness and Work-Hardening: Materials with high hardness, such as tool steels and titanium alloys, can withstand higher cutting forces, which helps maintain part accuracy. However, these materials may also exhibit work-hardening, requiring careful management of cutting parameters to prevent tool wear and dimensional changes.

-

Thermal Stability: Materials with low thermal conductivity, like ceramics and some alloys, are less affected by temperature changes during machining, maintaining dimensional stability and preventing deformation during the cutting process.

Material Uniformity:

Consistency in the material's structure is crucial for achieving high precision. Variations in material density, grain structure, and chemical composition can cause inconsistencies during machining, leading to dimensional errors.

- Casting vs. Forging: Forged materials generally exhibit better uniformity and stronger mechanical properties compared to cast materials, which can have micro-structural variations that lead to inconsistencies in machining.

5. Precision Control Systems

Precision control systems are integral to maintaining tight tolerances in CNC machining. These systems ensure that the cutting tool moves exactly as instructed and compensates for external factors like thermal expansion and mechanical inaccuracies.

Servo Control Systems:

Servo motors are responsible for controlling the movement of the machine’s axes with extreme precision. They offer high torque and speed while ensuring accurate positioning, making them essential for high-precision CNC operations.

-

Closed-Loop Feedback: Servo systems typically use closed-loop feedback, where position and velocity sensors continually monitor the movement of the machine components. This data is fed back to the control system, which makes real-time adjustments to maintain position accuracy.

-

Microstepping: Many CNC machines use microstepping in servo control to achieve finer movement resolution. Microstepping divides each full step of the motor into smaller increments, allowing for smoother movement and higher positioning accuracy.

Feedback Mechanisms:

Closed-loop feedback systems ensure that any discrepancies in the machine’s movement are quickly detected and corrected. These systems rely on encoders, resolvers, and linear scales to continuously monitor the position and speed of the machine’s moving parts.

- Error Detection and Correction: Feedback systems use algorithms to compare the actual position of the machine’s axis with the programmed position. If discrepancies are detected, adjustments are made in real-time, ensuring that the tool stays within the required tolerance limits.

6. Measurement and Quality Control

Measurement and inspection are critical to ensuring that CNC-machined parts meet the specified tolerances. Advanced measurement tools and techniques are used throughout the machining process to ensure the highest level of precision.

High-precision Measurement Tools:

Using advanced measurement tools, such as Coordinate Measuring Machines (CMMs), laser interferometers, and optical measurement systems, manufacturers can check the accuracy of each part during and after machining.

-

Laser Interferometers: These instruments use laser beams to measure linear motion with incredible accuracy, often to the nanometer level. They help ensure that the machine’s axes are positioned correctly throughout the machining process.

-

CMMs with Touch Probes: CMMs equipped with touch probes can measure complex geometries with high precision. These machines can perform both 3D measurements and surface scanning to verify that the final product matches the CAD model.

In-process Monitoring:

Real-time monitoring is essential for maintaining high precision in CNC machining. In-process measurement tools, such as laser scanners and touch probes, continuously monitor the dimensions of the workpiece while machining is underway.

- Real-time Adjustments: If in-process measurements detect any deviation from the required tolerances, the CNC system can adjust cutting speeds, tool paths, or feed rates to correct any errors immediately.

Part Inspection and Verification:

Once machining is complete, the final product undergoes a rigorous inspection process. This typically includes dimensional checks, surface finish analysis, and sometimes non-destructive testing (NDT) to verify the part's structural integrity.

- Surface Finish Testing: High-precision surface finish tools, such as profilometers, are used to measure the smoothness and texture of the part’s surface. These tests ensure that the machined part meets not only dimensional tolerances but also quality standards in terms of surface finish.

7. Thermal Control in the Machining Process

Thermal effects can cause dimensional instability in machined parts, particularly when machining high-speed or high-precision components. Proper thermal management is essential to maintaining the accuracy of the machining process.

Thermal Expansion and Errors:

Heat generated during machining can lead to thermal expansion, causing both the tool and the workpiece to change shape. This expansion can distort the final part, especially when working with materials that have a high coefficient of thermal expansion (CTE).

- Compensation Mechanisms: To counteract thermal expansion, many CNC systems are equipped with thermal compensation systems that dynamically adjust for temperature variations. These systems use sensors to monitor the temperature of the spindle and other critical components, ensuring that the machine compensates for any distortions caused by heat.

Cooling Systems and Temperature Control:

Advanced cooling systems help regulate the temperature of both the tool and workpiece, preventing excessive heat buildup that can affect machining precision.

- Coolant Management: Using high-performance coolants like oil-based fluids or specialized cutting oils helps reduce friction and dissipate heat during machining. Cooling systems also ensure the machine components are kept within a stable operating temperature range, reducing thermal deformation.

8. Conclusion

Achieving high precision in CNC machining is a complex process that relies on a synergy of advanced technologies, high-quality materials, and rigorous monitoring and control mechanisms. By leveraging precise programming, top-tier equipment, superior tooling, advanced control systems, and sophisticated measurement tools, manufacturers are able to create parts with tolerances that are often within microns.

As CNC technology continues to evolve, future advancements in automation, real-time feedback, and material sciences will further enhance the capabilities of CNC machining. With the combination of these innovative technologies, CNC machining will continue to drive progress in industries requiring extreme precision, including aerospace, automotive, medical devices, and electronics.

FAQ:

How are CNC machines so precise?

CNC machines achieve precision through a combination of advanced control systems, high-quality components, and careful calibration. The key elements include:

- Closed-loop Feedback Systems: Continuous real-time adjustments using encoders, resolvers, and other sensors ensure precise movements.

- High-Quality Components: Precision guides, ball screws, and linear rails minimize mechanical play, enhancing accuracy.

- Advanced CNC Programming: G-codes and M-codes direct machine movements down to the micrometer level, allowing exact control over tool paths.

- Precision Tooling and Materials: Specialized cutting tools and workpiece materials are chosen to maintain stable dimensions during the machining process.

What is the maximum precision of CNC?

The maximum precision of CNC machines can reach up to 0.0001 inches (2.5 microns) in some high-end machines, such as those used in aerospace or medical manufacturing. Some systems, like laser interferometers and coordinate measuring machines (CMMs), can achieve precision even beyond that, depending on the machine’s configuration and the complexity of the task.

How could precision be achieved in the construction of a CNC machine?

Achieving precision in the construction of a CNC machine involves:

- High-Quality Materials: Choosing materials with low coefficients of thermal expansion to minimize thermal deformation.

- Rigorous Manufacturing Processes: Using precision machining techniques to manufacture machine components, ensuring they meet strict tolerances.

- Fine Calibration and Alignment: Machine elements like spindles, guides, and motors must be carefully aligned and calibrated to prevent any mechanical inaccuracies.

- Advanced Control Systems: Implementing sophisticated numerical control systems with real-time feedback loops to ensure accurate machine movements.

What is the most precise CNC?

The most precise CNC machines are typically high-end multi-axis milling machines used in industries such as aerospace, medical, and electronics. These machines can achieve tolerances as tight as 0.0001 inches or 2.5 microns. Machines from brands like Haas, DMG Mori, and Hurco, along with specialized machines using laser interferometry or EDM (Electrical Discharge Machining), are known for their exceptional precision.