Hey there! Let me ask you this—have you ever ordered something, expecting top-notch quality, only to be disappointed when it arrived? That frustration, whether it’s a small flaw or a major issue, sticks with you, doesn’t it? Now, imagine being a manufacturer. That same disappointment could be what your buyers feel if quality control isn’t up to par.

As a manufacturer, we know that our buyers have high expectations—and they should. They rely on us to deliver precision, reliability, and value. But here’s the problem: even a small defect can lead to returns, complaints, or worse, a loss of trust. And trust me, once that trust is shaken, it’s a tough climb back.

Quick Answer:

Manufacturers can improve quality control and satisfy buyers by implementing robust Quality Management Systems (e.g., ISO 9001), leveraging advanced technologies like AI-powered inspections and IoT-based monitoring, and fostering a culture of quality within the organization. Key strategies include:

- Standardizing processes: Use a QMS to ensure consistent quality across production.

- Automating quality checks: Utilize robotics, automated inspection systems, and real-time data analytics to minimize errors.

- Investing in employee training: Equip teams with skills to maintain and improve quality.

- Applying Statistical Process Control (SPC): Monitor process variations to prevent defects.

- Strengthening supplier relationships: Ensure high-quality raw materials through audits and collaboration.

- Implementing comprehensive inspections: Conduct quality checks at all production stages, from raw materials to finished goods.

- Gathering customer feedback: Use surveys and reviews to refine processes and address issues proactively.

Why is Quality Control Crucial for Buyer Satisfaction?

Quality control isn't just a box to tick; it's the foundation of customer satisfaction, trust, and long-term business success. Below, we delve into why quality control is vital for fostering buyer satisfaction and ensuring a competitive edge in the marketplace.

Meeting Expectations

Customers purchase products with specific expectations in mind—functionality, durability, performance, and aesthetics. Quality control ensures that these expectations are consistently met or even exceeded.

- Delivering on Promises: A product that performs as promised creates positive experiences and strengthens customer satisfaction. Quality control is not just about avoiding defects; it’s about fulfilling the value proposition.

- Example in Action: A premium smartphone buyer expects a flawless touchscreen, long battery life, and a high-quality camera. Quality control ensures each device meets these standards, leading to a positive user experience.

- Consistent Quality Across Batches: Buyers expect uniformity. Whether ordering one unit or thousands, consistent quality ensures trust in the supplier's ability to deliver.

Building Trust and Loyalty

Reliable quality fosters trust between a company and its buyers, which is essential for creating long-term business relationships.

- Establishing Confidence: High-quality products delivered consistently build buyer confidence in the brand. This trust encourages repeat purchases and strengthens brand loyalty.

- Valuable Asset in Competitive Markets: Customers who trust a brand are more likely to choose it over competitors, even when alternatives are available. This reduces the need for costly customer acquisition efforts.

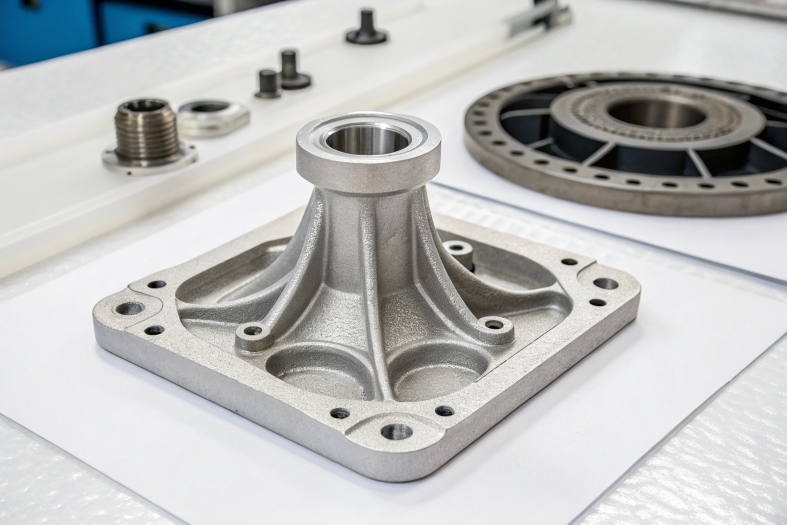

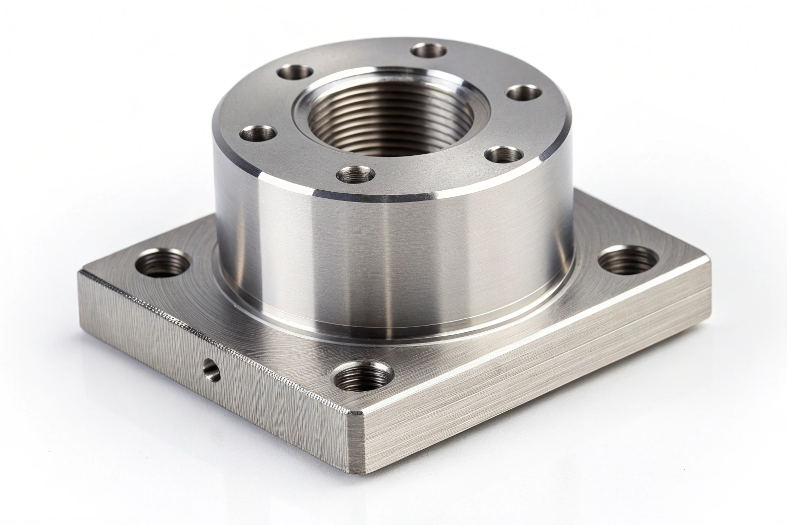

- Example: A customer who consistently receives defect-free CNC-machined parts will likely return for future projects, strengthening the relationship and reducing churn.

Reducing Returns and Complaints

Defective products result in returns, complaints, and warranty claims, all of which can be costly for businesses. Robust quality control minimizes these issues.

- Cost Efficiency: Fewer defects mean reduced expenses for handling returns, shipping replacements, and processing refunds. Additionally, fewer complaints translate to less administrative overhead.

- Improved Customer Satisfaction: A lower defect rate leads to happier buyers and enhances the overall brand perception.

- Statistical Insight: According to a Frost & Sullivan report, companies with robust QC systems see 25% fewer product returns than industry averages.

Protecting Brand Reputation

In today's interconnected world, quality failures can quickly escalate into public relations disasters. Negative reviews and social media backlash can significantly damage a brand’s reputation.

- Safeguarding Against Negative Publicity: Quality control acts as a shield against defects reaching buyers, preserving brand image and trust.

- Reputation as a Competitive Asset: A reputation for superior quality can set a company apart in crowded markets.

- Example: A widely publicized product recall due to defective components can erode customer trust and lead to years of reputation rebuilding. Conversely, brands known for consistent quality, like Toyota, maintain their strong market positions even in competitive industries.

Competitive Advantage

In saturated markets, quality is a key differentiator that sets companies apart and attracts discerning buyers.

- Commanding Higher Prices: Customers are often willing to pay a premium for reliable, high-quality products. This allows companies to increase their market share and build brand equity.

- Standing Out in the Market: Superior quality positions a manufacturer as a leader in its industry, appealing to buyers who prioritize reliability.

- Case Highlight: Lexus and Toyota dominate the automotive industry by focusing on build quality and reliability, earning customer loyalty and higher price points.

Key Strategies for Improving Quality Control

Improving quality control requires a comprehensive and multi-faceted approach. Below is a detailed look at the most effective strategies manufacturers can adopt to ensure consistent quality and buyer satisfaction.

Implementing a Robust Quality Management System (QMS)

- What is a QMS?

A Quality Management System (QMS) is a structured framework for documenting processes, procedures, and responsibilities to achieve quality objectives. ISO 9001, the internationally recognized standard, provides guidelines for consistent product and service delivery that meets customer and regulatory requirements. - Benefits of a QMS:

- Standardized Processes: Reduces variability and ensures consistent product quality.

- Documentation: Enhances traceability, facilitates audits, and supports continuous improvement.

- Continuous Improvement: Encourages a "Plan-Do-Check-Act" (PDCA) cycle to identify areas for improvement and implement corrective actions.

- Example:

A CNC machining company achieved ISO 9001 certification by documenting their processes, implementing quality checks, and establishing a system to handle non-conformances. This led to a significant reduction in defects, improved on-time delivery, and increased customer trust, ultimately securing contracts with larger clients requiring ISO-certified suppliers.

Utilizing Advanced Technology and Automation

- Role of Automation:

Automation minimizes human error, increases production speed, and ensures consistent quality. Automated systems can perform repetitive tasks with greater precision and reliability. - Examples:

- Automated Inspection Systems: Cameras and sensors detect dimensional inaccuracies, surface imperfections, and missing components.

- Robotics: Perform tasks like welding, assembly, and packaging with high precision.

- AI-Powered Quality Checks: Machine learning algorithms analyze inspection data to identify patterns and predict defects.

- Trend:

IoT devices enable real-time quality monitoring by collecting data on parameters like temperature and vibration. This allows manufacturers to detect anomalies early and prevent defects.

Investing in Employee Training and Development

- Importance of Skilled Workers:

Advanced technology still requires skilled workers to operate, maintain equipment, interpret data, and make critical decisions. - Training Programs:

- Quality Standards: Industry-specific standards (e.g., ISO, ASTM) and internal requirements.

- Inspection Techniques: Visual inspection, measurement techniques, and equipment use.

- Problem-Solving: Root cause analysis and Corrective and Preventive Action (CAPA) methodologies.

- Example:

A manufacturing company reduced defect rates significantly by implementing training programs focused on standardized procedures, proper tool usage, and quality awareness.

Implementing Statistical Process Control (SPC)

- What is SPC?

SPC uses statistical tools to monitor production processes. Control charts display variations, helping distinguish common cause variation (inherent to the process) from special cause variation (specific, correctable issues). - Benefits:

Early detection of deviations prevents defects and reduces waste. - Example:

A CNC machining company tracked part diameters using SPC control charts. By identifying a tool wear trend, they replaced the tool before producing out-of-spec parts, reducing rework and scrap costs.

Strengthening Supplier Relationships

- Importance of Quality Raw Materials:

High-quality inputs are critical for achieving desired product standards. - Strategies for Supplier Management:

- Supplier Selection: Clear criteria based on quality and reliability.

- Supplier Audits: Regular assessments of quality processes and systems.

- Collaboration: Open communication to address issues and drive improvements.

- Example:

A medical equipment manufacturer conducted regular supplier audits and provided training on regulatory requirements. This collaboration ensured consistent material quality, meeting stringent compliance standards.

Implementing a Comprehensive Inspection and Testing Program

- Types of Inspection:

- Incoming Inspection: Verify raw materials meet specifications upon delivery.

- In-Process Inspection: Monitor quality during manufacturing to detect defects early.

- Final Inspection: Ensure finished products meet quality standards before shipment.

- Testing Methods:

- Destructive Testing: Evaluates material properties through tests like tensile strength.

- Non-Destructive Testing (NDT): Uses techniques like X-ray or ultrasonic inspection without damaging products.

- Tip:

Combining manual and automated inspections increases accuracy, with manual inspections detecting subtle defects and automated systems handling high-volume checks.

Encouraging a Culture of Quality

- Creating a Quality-Focused Environment:

Fostering a culture of quality ensures all employees actively participate in maintaining high standards. - Key Elements:

- Management Commitment: Leadership must prioritize quality and allocate resources.

- Employee Involvement: Empower employees to identify and address quality issues.

- Continuous Improvement: Regularly review and refine quality processes.

- Best Practice:

Establish a no-fear environment where employees feel safe reporting potential issues, promoting proactive problem-solving.

Gathering and Analyzing Customer Feedback

- Value of Customer Feedback:

Buyers’ experiences provide insights into real-world product performance and highlight areas for improvement. - Methods for Collecting Feedback:

- Surveys: Targeted questions on product and service satisfaction.

- Reviews: Monitor online platforms and social media for customer opinions.

- Customer Service Interactions: Analyze common complaints for actionable trends.

- Using Feedback for Improvement:

Feedback can be used to revise processes, update tolerance standards, and implement stricter controls. - Case Example:

An automotive parts supplier addressed feedback on dimensional inconsistencies by revising machining tolerances and improving process controls, boosting satisfaction and repeat orders.

Conclusion

Phew, that was a lot to unpack, right? But hey, quality control is one of those areas where effort truly pays off. Whether it’s implementing a solid QMS, investing in advanced tech, training your team, or building strong supplier relationships, every little step adds up to a big impact on your buyers' satisfaction and your business growth.

At the end of the day, it’s all about keeping promises—delivering what your customers expect and even surprising them with more. Trust me, the journey of improving quality is ongoing, but the rewards? Absolutely worth it.

If you’re looking for CNC machining solutions from a team that takes quality as seriously as you do, check out www.promachined.com. Let’s talk about how we can help you deliver the best to your buyers. Feel free to drop me a message anytime—we’re here to help! 😊

FAQ:

What are the key ways to improve quality control in manufacturing?

Improving quality control in manufacturing involves a multi-faceted approach. Key strategies include:

- Implementing a robust Quality Management System (QMS): Standards like ISO 9001 help standardize processes and encourage continuous improvement.

- Leveraging advanced technology and automation: Use AI-powered inspections, robotics, and IoT-based real-time monitoring to reduce errors and enhance consistency.

- Ensuring skilled personnel through training and development: Comprehensive programs ensure employees understand and maintain quality standards.

- Applying Statistical Process Control (SPC): Monitor process variations using data analysis and control charts to identify and address inconsistencies.

- Strengthening supplier relationships: Ensure raw materials and components meet quality requirements through audits and collaboration.

- Implementing comprehensive inspection and testing programs: Conduct inspections at all stages, from incoming materials to final products, to prevent defects.

- Fostering a culture of quality: Engage employees at all levels in maintaining and improving quality while encouraging proactive problem-solving.

- Gathering and analyzing customer feedback: Identify areas for improvement and address customer concerns effectively to enhance product quality.

How does effective quality control benefit manufacturers?

Effective quality control delivers several significant benefits:

- Increased customer satisfaction and loyalty: By consistently meeting or exceeding expectations, fostering trust and repeat business.

- Reduced returns, complaints, and warranty claims: Saving costs and improving operational efficiency through defect prevention.

- Enhanced brand reputation and trust: Building a positive image and attracting new customers with reliable quality.

- Increased efficiency and reduced waste: Streamlining processes and maintaining consistent quality.

- Stronger competitive advantage: Differentiating products and services based on superior quality, allowing manufacturers to command higher prices.

How does quality control contribute to customer satisfaction?

Quality control is essential for ensuring customer satisfaction by:

- Meeting expectations: Delivering products that fulfill promised functionality, performance, and durability.

- Building trust: Reliable quality fosters long-term relationships and repeat business with customers.

- Minimizing negative experiences: Reducing defects, returns, and complaints enhances customer confidence and loyalty.

- Protecting brand reputation: By consistently delivering high-quality products, companies strengthen their market position and maintain customer trust.

What is the role of technology in modern quality control?

Technology plays a transformative role in modern quality control by:

- Automating inspection and testing processes: Increasing accuracy, speed, and reducing human error.

- Facilitating real-time monitoring: IoT devices and analytics provide continuous data, enabling early defect detection.

- Improving process control: Tools like SPC enable data-driven process adjustments for better outcomes and reduced variability.

- Supporting predictive maintenance: Identifying potential equipment failures before they impact quality, minimizing downtime.

- Enhancing scalability: Advanced technologies handle large production volumes while maintaining consistent quality.

Why is quality control so important for manufacturing success?

Quality control is critical to manufacturing success because it:

- Drives customer satisfaction: Ensures products consistently meet or exceed expectations.

- Boosts operational efficiency: Prevents defects, reduces waste, and minimizes downtime.

- Protects against reputation risks: Avoids quality failures that could harm brand trust and customer loyalty.

- Ensures compliance with regulatory and industry standards: Mitigates legal and financial risks by consistently meeting requirements.

- Provides a competitive edge: Allows companies to differentiate based on quality, retain customers, and command higher prices.