Have you ever wondered how those flawless luxury watches, sleek high-end electronics, or precision-crafted automotive parts come to life? Let me tell you—it’s not magic, it’s CNC machining.

I know as a customer, quality is non-negotiable. Whether you're looking for precision, durability, or stunning aesthetics, CNC machining plays a critical role in delivering exactly that. But here’s the thing: not all manufacturing processes can achieve the same level of perfection. CNC machining is in a league of its own, designed to meet the high standards that industries like automotive, electronics, and luxury goods demand.

Let me take you through the details, and by the end of this, I’m confident you’ll see why CNC machining is the backbone of high-end manufacturing.

Quick Answer:

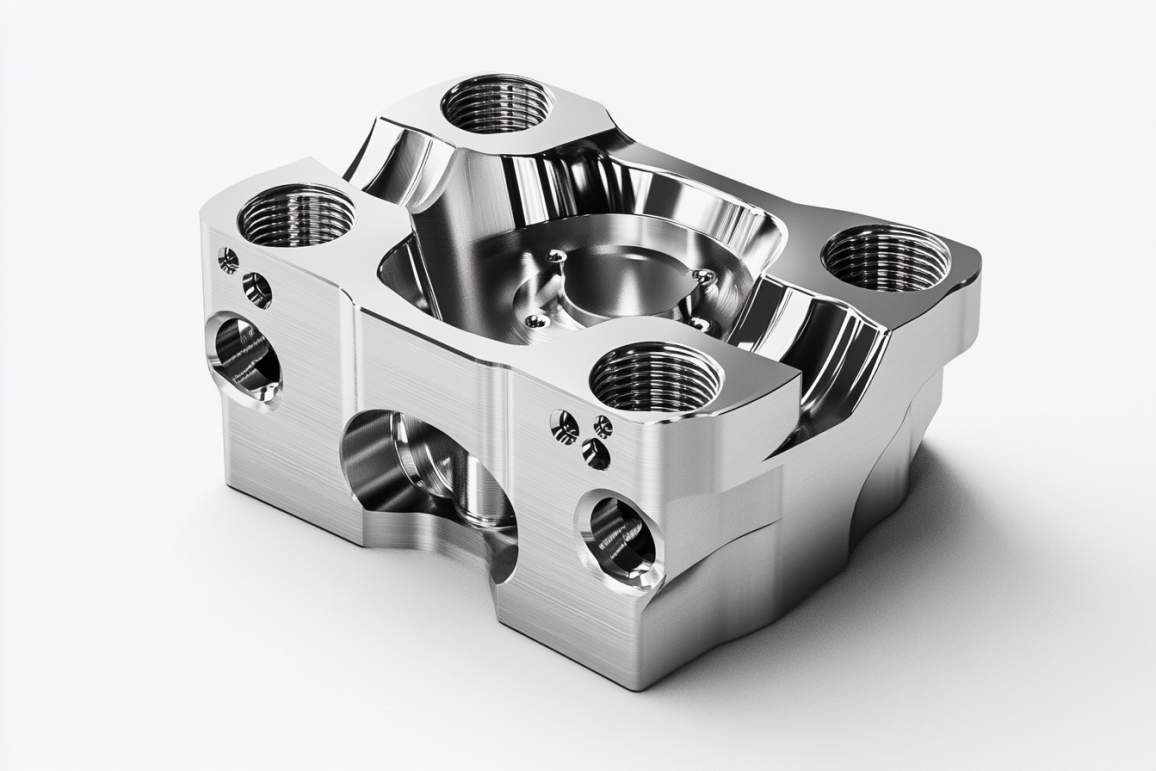

CNC machining is essential for high-end consumer goods manufacturing, delivering unparalleled precision, durability, and intricate designs demanded by luxury markets. This automated process uses computer-controlled tools and advanced software to create complex geometries and tight tolerances, ensuring exceptional quality and consistency in products like luxury watches, sleek electronics, and high-performance automotive parts. By replacing manual operations with precise programming, CNC machining enhances efficiency and enables bespoke customization, making it indispensable for industries where both aesthetics and functionality are paramount.

What is CNC Machining?

CNC (Computer Numerical Control) machining represents a paradigm shift in manufacturing, replacing manual control with sophisticated computer programming to direct machine tools. This automation significantly enhances precision, consistency, and efficiency while enabling the creation of complex geometries and intricate designs that are virtually impossible to achieve through traditional methods. In high-end consumer goods manufacturing, CNC machining is indispensable for meeting the exacting standards of quality, aesthetics, and performance demanded by discerning consumers.

The CNC Machining Process: A Multi-Stage Operation

Each stage of the CNC machining process is critical to ensuring the final product meets high standards of quality and precision.

1. CAD/CAM Design

This stage forms the foundation of the entire CNC machining process.

-

CAD (Computer-Aided Design):

Designers use specialized CAD software like SolidWorks, AutoCAD, or CATIA to create detailed 2D or 3D digital models of the desired component. These models define every dimension, feature, and tolerance, serving as a blueprint for manufacturing. For high-end goods, special attention is given to surface finish, aesthetic details, and ergonomic considerations. -

CAM (Computer-Aided Manufacturing):

Once the CAD model is finalized, CAM software such as Mastercam, PowerMill, or GibbsCAM translates the design into precise G-code instructions for the CNC machine. This involves:- Defining toolpaths, cutting speeds, and feed rates.

- Optimizing machining parameters for accuracy, surface finish, and efficiency.

- Simulating the machining process to identify potential collisions or errors before production, saving time and materials.

2. Machine Setup

Proper preparation of the CNC machine is crucial for accurate and efficient operations.

-

Workpiece Mounting:

The raw material (workpiece) is securely clamped onto the machine's worktable or fixture to ensure stability and prevent vibrations during machining. Specialized fixtures are often designed for precise and repeatable positioning. -

Tooling:

Cutting tools (e.g., end mills, drills, turning inserts) are selected based on the material and the features of the desired component. Tools are mounted in the machine’s holders and calibrated for accuracy. Advanced CNC machines often feature automatic tool changers for seamless transitions between tools. -

Zero Point Setting:

The machine's coordinate system is aligned with the workpiece by establishing a zero point, or work coordinate system, ensuring that the programmed toolpaths are accurately followed.

3. Cutting and Finishing Operations

This is the core of the CNC machining process, where material removal and refinement occur.

-

Cutting:

The CNC machine executes G-code instructions, guiding cutting tools along precise toolpaths to shape the workpiece. Cutting parameters such as speed, feed rate, and depth of cut are meticulously controlled to achieve the desired dimensions and surface quality. Coolants are often used to dissipate heat, prolong tool life, and enhance surface finishes. -

Finishing:

After initial cutting, finishing passes use finer tools and optimized parameters to refine surface finishes and meet tight tolerances. For high-end products, additional processes like polishing, lapping, or honing are performed to ensure superior aesthetic and functional quality.

Common CNC Machining Processes for High-End Goods

-

Milling

- Description: Milling employs rotating multi-point cutting tools to remove material and create complex 3D shapes, slots, and contours.

- Applications: Used for crafting intricate watch cases, jewelry components, and detailed engravings in luxury goods.

- Precision: Capable of achieving tolerances as tight as ±0.01 mm, suitable for high-end applications.

-

Turning

- Description: Turning involves rotating the workpiece while a stationary cutting tool shapes it, ideal for cylindrical or conical parts.

- Applications: Commonly used for watch bezels, pen barrels, and other axisymmetric components requiring precision and fine finishes.

- Precision: Ensures uniformity with tight tolerances and smooth surface finishes.

-

Grinding

- Description: Grinding uses abrasive wheels to achieve extremely smooth surfaces and tight tolerances.

- Applications: Frequently used for finishing gears, bearings, and watch movements, achieving mirror-like finishes.

- Surface Finish: Achieves surface roughness as smooth as Ra 0.2 µm, essential for aesthetic and functional excellence.

-

Electrical Discharge Machining (EDM)

- Description: EDM uses electrical discharges (sparks) to remove material, ideal for hard-to-machine materials and intricate designs.

- Applications: Essential for creating jewelry dies, complex watch components, and fine details on luxury tools and instruments.

- Benefits: Non-contact machining minimizes deformation, enabling the production of ultra-fine features.

Why CNC Machining Stands Out in Luxury Manufacturing

- Unmatched Precision: CNC machines operate with micron-level accuracy, ensuring every component meets the highest standards.

- Consistency Across Batches: Whether for bespoke items or mass production, CNC machining guarantees uniform quality.

- Material Versatility: From precious metals like gold and platinum to advanced composites and high-performance polymers, CNC machining supports a wide range of materials.

- Complexity and Innovation: Enables the creation of intricate designs and geometries, pushing the boundaries of modern luxury manufacturing.

Applications of CNC Machining in High-End Consumer Goods

CNC machining plays a pivotal role in the creation of high-end consumer goods, enabling manufacturers to achieve exceptional levels of precision, quality, and design complexity. Its versatility allows for applications across diverse industries, each benefiting from its unique capabilities.

Luxury Watches and Jewelry

In the realm of luxury timepieces and exquisite jewelry, CNC machining is not merely a manufacturing process—it is an art form.

-

Intricate Components:

CNC machining is essential for crafting the intricate components that comprise a luxury watch, including cases, bezels, crowns, pushers, and even movement parts like bridges, plates, and rotors. Using multi-axis CNC milling machines, these parts are machined from solid blocks of metal with extraordinary precision, ensuring perfect fit, reliability, and longevity. -

Precision Engraving and Detailing:

CNC engraving enables the creation of intricate patterns, logos, and personalized inscriptions on watch cases, dials, and movements. Laser-guided CNC systems further enhance the precision, delivering the fine details collectors and connoisseurs highly value. -

High-End Materials:

Luxury watches and jewelry frequently use materials such as titanium, gold, platinum, and exotic alloys. CNC machining excels at working with these high-value materials, ensuring minimal waste and maintaining their structural integrity. Tight tolerances allow for impeccable craftsmanship even with hard or brittle materials. -

Complex Geometries:

Modern designs featuring complex curves and contours are easily achieved with multi-axis CNC machining. This technology empowers designers to push creative boundaries, resulting in visually stunning, unique pieces.

Example: Rolex utilizes CNC machining for its precision watch movements and detailed case designs, ensuring that each piece meets the brand's high standards for quality and craftsmanship.

High-End Electronics

In the fast-paced world of luxury electronics, where both aesthetics and performance are paramount, CNC machining offers a distinct advantage.

-

Precise Enclosures and Components:

CNC machining is used to manufacture enclosures and internal components for smartphones, laptops, tablets, and high-end audio equipment. These parts not only provide structural integrity but also enhance the product's overall design and feel. -

Tight Tolerances for Optimal Performance:

Electronic devices require precise alignment of internal components for functionality. CNC machining ensures tight tolerances, enabling seamless fit and alignment critical for high-performance electronics. -

Surface Finishing for a Premium Look and Feel:

CNC machining supports a variety of surface finishes, such as brushed, polished, bead-blasted, and anodized. These finishes provide a premium tactile experience and elevate the product's visual appeal. -

Heat Dissipation:

Efficient thermal management is critical in high-performance electronics. CNC machining allows for the creation of intricate heat sinks and cooling channels within enclosures, ensuring devices remain cool during operation.

Example: Apple uses CNC machining to produce its unibody MacBook and iPhone enclosures, blending sleek design with robust functionality.

Luxury Automotive

The luxury automotive sector leverages CNC machining to achieve both performance optimization and aesthetic refinement.

-

High-Performance Engine Parts:

CNC machining is integral to manufacturing engine components like pistons, cylinder heads, and camshafts. Tight tolerances ensure these parts contribute to optimal engine efficiency, performance, and reliability. -

Interior Trims and Exterior Components:

Intricate interior trims, dashboard elements, and exterior styling components are created using CNC machining. These parts often feature complex curves and surface finishes that enhance the vehicle’s luxurious appeal. -

Custom Parts and Accessories:

CNC machining enables the production of bespoke parts, such as personalized trims, custom wheels, and performance upgrades tailored to customer preferences. -

Lightweight Materials:

The automotive industry increasingly uses materials like aluminum, magnesium, and carbon fiber composites to improve performance and fuel efficiency. CNC machining is well-suited for crafting complex shapes from these materials while maintaining strength and durability.

Example: Lamborghini relies on CNC machining for both high-performance components and sculpted aerodynamic designs, delivering a blend of luxury and engineering excellence.

High-End Fashion and Accessories

CNC machining has carved out a significant role in the creation of luxury fashion and accessories, blending precision with creativity.

-

Precision Hardware:

CNC machining is used to create hardware such as buckles, buttons, clasps, and zippers for luxury handbags, clothing, and footwear. These components contribute to both the functionality and aesthetic appeal of the final product. -

Custom Eyewear Frames:

CNC machining allows for the creation of bespoke eyewear frames with unique shapes and precise fits. Frames made from titanium, stainless steel, or acetate achieve both durability and style, complementing the wearer’s individuality. -

Intricate Designs and Embellishments:

Accessories like jewelry, belts, and handbags benefit from CNC machining’s ability to produce intricate patterns and designs. This technology enables designers to craft pieces that are both functional and artistically distinctive.

Example: High-end brands like Cartier and Gucci use CNC machining to create luxurious accessories that emphasize quality and creativity.

Advantages of Using CNC Machining for High-End Goods

CNC machining offers a comprehensive array of benefits, making it the preferred manufacturing method for high-end consumer goods. Its ability to achieve exceptional precision, handle complex geometries, and work with versatile materials ensures superior product quality, functionality, and aesthetic appeal.

Precision and Accuracy

- Tight Tolerances: CNC machining delivers tolerances measured in micrometers (µm), essential for components like watch movements, optical instruments, and precision machinery. This ensures perfect fit and functionality.

- Consistent Quality: Automation minimizes human error, maintaining uniform quality across all units, which is critical for upholding brand reputation in luxury markets.

- Dimensional Accuracy: CNC machines replicate complex geometries and dimensions with precision, ensuring the final product matches the original CAD design, particularly important for intricate assemblies and high-end designs.

Complex Geometries

- Intricate Shapes and Designs: CNC machining creates complex 3D shapes, detailed surface textures, and intricate curves that are often impossible to achieve with traditional methods. This capability enables the production of visually stunning and innovative designs.

- Multi-Axis Machining: Advanced multi-axis CNC machines, such as 5-axis machining centers, allow for the production of parts with complex contours and undercuts in a single setup. This reduces the need for multiple operations, improving both accuracy and efficiency.

Material Versatility

- Wide Range of Materials: CNC machining supports a variety of materials, including:

- Metals: Aluminum, steel, titanium, gold, and platinum.

- Plastics: ABS, polycarbonate, acrylic.

- Composites: Carbon fiber, fiberglass.

- Others: Wood and stone for niche applications.

- Difficult-to-Machine Materials: CNC machining excels at processing hard and brittle materials, such as titanium and exotic alloys, which are commonly used in high-end applications requiring exceptional properties.

Repeatability and Scalability

- Consistent Production: Once optimized, CNC programs ensure consistent results across all production units, essential for maintaining the quality of luxury goods.

- Scalability: CNC machining is suitable for both small-batch prototype production and large-scale manufacturing runs. This flexibility makes it ideal for luxury markets, where production volumes may vary with demand.

Customization

- Bespoke Designs: CNC machining supports the creation of personalized, one-of-a-kind products tailored to individual preferences, a hallmark of the luxury industry.

- Rapid Prototyping: CNC machining allows for quick production of prototypes, enabling rapid iteration and refinement before full-scale manufacturing. This accelerates product development and reduces time-to-market.

Surface Finish

- High-Quality Finishes: CNC machining achieves a wide range of finishes, from rough cuts to mirror-like polishing, enhancing the visual and tactile appeal of high-end goods.

- Surface Texture and Details: Intricate textures, engravings, and patterns can be precisely crafted, adding exclusivity and aesthetic value to luxury items.

Challenges and Considerations

While CNC machining offers unparalleled advantages, certain challenges must be managed to optimize its use for high-end goods.

Cost

- High Initial Investment: Advanced CNC machines require significant capital outlay, and skilled operators and programmers add to the cost. These investments are necessary to achieve the precision and quality demanded by luxury markets.

- Tooling Costs: Cutting tools, especially those for hard materials or fine finishes, are expensive and require regular maintenance and replacement to maintain quality.

Setup Time

- Programming and Calibration: Developing G-code programs for complex parts and calibrating machines is time-intensive. This is especially true for multi-axis machining or intricate designs.

- Fixture Design: Custom fixtures may be required to securely hold workpieces during machining, adding to setup time and costs.

Material Waste

- Subtractive Manufacturing: CNC machining removes material to achieve the desired shape, generating waste. This is particularly significant when machining costly materials like gold or platinum.

- Waste Minimization: Advanced strategies like near-net-shape machining and optimized toolpaths reduce material loss, helping to address this concern in high-end manufacturing.

Case Studies

Examining how leading brands utilize CNC machining provides valuable insights into its impact on product quality, design, and brand image. The following examples highlight how Rolex, Apple, and Lamborghini leverage CNC machining to deliver exceptional precision, performance, and aesthetics.

Rolex: Precision Watchmaking

Rolex, a symbol of luxury and precision timekeeping, integrates CNC machining extensively in its manufacturing process to uphold its reputation for excellence.

-

Movement Components:

The movement is the heart of a Rolex watch, composed of hundreds of intricately shaped components. CNC machining ensures the production of these components to micrometer-level tolerances, enabling unmatched accuracy and reliability. Critical parts like gears, pinions, bridges, and plates are machined from premium metals using multi-axis CNC milling machines and Swiss-type lathes. -

Case and Bracelet Manufacturing:

Rolex watch cases and bracelets are crafted with extraordinary attention to detail using CNC machining. Cases are machined from solid blocks of Oystersteel (904L stainless steel), gold, or platinum, providing exceptional durability and corrosion resistance. CNC machining allows the creation of complex case designs and ensures precise fitting of bezels, crystals, and case backs. Similarly, individual bracelet links are precisely machined and then assembled by hand. -

Quality Control and Finishing:

CNC machining plays a pivotal role in maintaining quality control by ensuring consistent dimensions and surface finishes. Post-machining processes, such as polishing, brushing, and engraving, are also supported by CNC systems, delivering Rolex's signature flawless finish. -

Vertical Integration:

Rolex’s vertically integrated manufacturing approach allows the company to retain complete control over its production processes. This enables full utilization of CNC machining capabilities to ensure consistent quality and continuous innovation.

Example: Rolex’s fluted bezels, a signature design element, are manufactured with multi-axis CNC machining to achieve perfect symmetry and sharpness, reflecting the brand’s meticulous attention to detail.

Apple: Iconic Product Design

Apple has revolutionized consumer electronics with its minimalist and functional designs, relying on CNC machining to bring these concepts to life.

-

Unibody Enclosures:

Apple pioneered the use of unibody enclosures for its MacBooks and other devices. These enclosures are milled from single blocks of aluminum using multi-axis CNC machines, resulting in durable, lightweight designs with seamless integration of components. -

Precision Component Manufacturing:

CNC machining ensures the precise production of internal components such as logic boards, heat sinks, and speaker grilles. This precision guarantees proper fit and function, enhancing device reliability and performance. -

Surface Finish and Aesthetics:

Surface treatments like anodizing, bead blasting, and polishing are made possible through CNC machining. These processes contribute to Apple’s signature sleek look and premium tactile experience. -

Design for Manufacturing (DFM):

Apple integrates manufacturing considerations into its design process, optimizing products for CNC machining. This collaboration ensures efficient production while maintaining the brand's iconic aesthetics.

Example: Apple’s unibody MacBook enclosures demonstrate how CNC machining delivers unparalleled strength and precision, enabling the seamless integration of ports, hinges, and keyboards.

Lamborghini: Blending Performance and Aesthetics

Lamborghini, a name synonymous with high-performance sports cars, leverages CNC machining to meet the dual demands of performance and aesthetics.

-

Engine Components:

Critical engine parts like cylinder heads, pistons, connecting rods, and crankshafts are manufactured using CNC machining. Tight tolerances ensure these components contribute to optimal engine performance, durability, and efficiency. -

Chassis and Suspension Components:

CNC machining is used to produce lightweight and strong chassis and suspension components, such as suspension arms, hubs, and brackets. These parts, often made from aluminum or titanium alloys, enhance vehicle handling and performance. -

Exterior and Interior Styling:

Intricate styling elements such as grilles, vents, and interior trims are crafted with CNC machining. These components play a key role in defining Lamborghini’s luxurious and distinctive appearance. -

Customization and Limited Editions:

CNC machining allows Lamborghini to offer extensive customization options, from bespoke interiors to unique exterior features. This capability also enables the production of limited-edition models with exclusive design elements, enhancing the brand’s exclusivity.

Example: The Aventador’s forged carbon fiber monocoque chassis is a result of advanced CNC machining, combining exceptional strength with reduced weight, which significantly enhances both performance and safety.

Materials Commonly Used in High-End CNC Machining

The selection of materials plays a critical role in high-end manufacturing, as each material brings unique properties that contribute to the final product's quality, functionality, and aesthetic appeal. CNC machining's versatility allows for the precision crafting of a wide range of materials, including metals, polymers, and composites.

Metals

Metals are the backbone of high-end CNC machining, offering durability, strength, and premium finishes essential for luxury products.

-

Titanium:

Known for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium is widely used in:- Luxury Watches: For cases, bezels, and bracelets, offering lightweight durability and resistance to scratches and corrosion.

- Aerospace and Automotive: In high-performance components where weight reduction and strength are critical.

- Medical Implants: Its biocompatibility makes titanium ideal for surgical instruments and implants.

-

Stainless Steel:

Valued for its durability, corrosion resistance, and aesthetic appeal, stainless steel is used in:- Watches and Jewelry: Specific grades provide excellent polishability and resistance to tarnish.

- Luxury Goods Hardware: Buckles, clasps, and fashion accessory components.

- Precision Instruments: Its stability and resistance make it ideal for tools and high-precision devices.

-

Gold:

A symbol of luxury, gold is used for its malleability and resistance to tarnishing:- Jewelry: A staple material for rings, necklaces, and bracelets.

- Electronics: Used in connectors and contacts for its conductivity and corrosion resistance.

- Luxury Watches: Often featured in cases, dials, and movements to enhance value and elegance.

-

Platinum:

Renowned for its density, durability, and rarity, platinum is used in:- High-End Jewelry: Offering unmatched durability and exclusivity.

- Luxury Watches: For cases and decorative elements, symbolizing prestige.

-

Aluminum:

Lightweight and machinable, aluminum alloys are used in:- Electronics Enclosures: Providing structural integrity and heat dissipation for laptops and smartphones.

- Automotive Components: Reducing weight and improving fuel efficiency in performance vehicles.

Polymers

Polymers offer versatility, lightweight properties, and ease of machining, making them ideal for various luxury applications.

-

Acrylic (PMMA):

A transparent thermoplastic with optical clarity and scratch resistance:- Displays and Lenses: Used for high-end optical components and protective covers.

- Decorative Elements: Colored and shaped for aesthetic purposes in luxury goods.

-

Delrin (POM):

Known for its high strength, stiffness, and low friction:- Gears and Bearings: Suitable for mechanical components in watches and electronics.

- Precision Parts: Provides stability and tight tolerances for intricate designs.

Composites

Composites bring a modern aesthetic and advanced performance characteristics to luxury goods.

- Carbon Fiber:

A composite material offering a high strength-to-weight ratio and a sleek look:- Luxury Automotive: Used in body panels, spoilers, and trims for weight reduction and enhanced performance.

- High-End Sports Equipment: Found in bicycles, tennis rackets, and golf clubs.

- Luxury Accessories: Crafted into wallets, pens, and watch cases for a contemporary feel.

Future Trends in CNC Machining for Luxury Manufacturing

CNC machining is constantly evolving, with new technologies and practices shaping its future in the production of high-end goods.

Integration with 3D Printing (Additive Manufacturing)

The combination of CNC machining and 3D printing is revolutionizing manufacturing processes:

-

Hybrid Manufacturing: Combining subtractive CNC machining with additive 3D printing allows for the creation of parts with complex internal geometries that were previously impossible.

- Applications: Hybrid methods are used to produce lightweight automotive parts and custom-designed watch cases.

- Efficiency: Near-net-shape preforms are 3D-printed and then finished with CNC machining for precision and smooth surfaces.

-

Rapid Prototyping and Customization: The synergy between these technologies accelerates product development and enables highly customized luxury goods.

Automation and AI in CNC Processes

Automation and artificial intelligence (AI) are transforming CNC machining, enhancing productivity and precision:

- Increased Automation: Robotics and automated material handling systems reduce labor costs and improve efficiency.

- AI-Powered Optimization: Machine learning algorithms optimize machining parameters, predict tool wear, and streamline quality control.

- Digital Twins: Virtual models of machines and processes allow for accurate simulations, reducing errors and improving efficiency.

Sustainable Manufacturing Practices

As sustainability becomes a priority, CNC machining is adapting to reduce environmental impact:

- Reduced Material Waste: Techniques like optimized toolpaths and near-net-shape machining minimize waste, particularly in expensive materials like gold and carbon fiber.

- Energy Efficiency: New CNC machines are designed to consume less power while maintaining high performance.

- Sustainable Materials: Recyclable and eco-friendly materials are increasingly used in luxury manufacturing.

Conclusion

CNC machining has undeniably transformed the manufacturing of high-end consumer goods, bridging the gap between precision, functionality, and luxury aesthetics. Whether it’s crafting intricate watch components, engineering high-performance automotive parts, or designing bespoke fashion accessories, CNC machining remains the backbone of modern luxury manufacturing.

If you’re interested in learning more about how CNC machining can elevate your products or need a reliable partner to deliver top-notch precision components, let’s chat! Visit www.promachined.com to explore our services, or reach out directly to discuss your next project. I’m always here to help and excited to collaborate on bringing your ideas to life.

Let’s make something extraordinary together!

FAQ:

What is CNC machining, and how is it used in manufacturing?

CNC (Computer Numerical Control) machining is an advanced automated manufacturing process that uses computer programming (G-code) to control machine tools. Unlike traditional manual methods, CNC machining ensures precision and efficiency by executing pre-programmed instructions to shape materials accurately.

The process involves cutting, milling, drilling, and grinding various materials, including metals (aluminum, steel, titanium), plastics, composites, and wood. It is used to produce components with tight tolerances, intricate geometries, and consistent quality. CNC machining's automation dramatically enhances productivity, accuracy, and repeatability, making it indispensable in modern manufacturing.

Is CNC machining suitable for high-volume production?

Yes, CNC machining is suitable for high-volume production while being equally versatile for small-batch production and rapid prototyping.

High-Volume Production:

Once CNC programs are optimized and machines are set up, they can efficiently produce large quantities of identical parts with minimal human intervention. This ensures cost-effectiveness and high throughput, especially in industries with standardized components.

Small-Batch and Prototyping:

CNC machining is also ideal for producing small batches and prototypes, enabling rapid design iterations and customization. This flexibility is particularly valuable in sectors requiring frequent design changes or highly specialized components.

What are the main advantages of CNC machining in the manufacturing industry?

CNC machining offers several key benefits that make it indispensable in modern manufacturing:

-

High Precision and Accuracy:

CNC machines achieve extremely tight tolerances, often measured in microns, ensuring precise dimensions and consistent quality across all parts. -

Complex Geometries:

CNC machining can create intricate 3D shapes and complex designs that are challenging or impossible to produce with traditional methods. -

Material Versatility:

CNC machines can work with a wide range of materials, including metals (e.g., titanium, stainless steel, gold), composites (e.g., carbon fiber, fiberglass), and polymers (e.g., Delrin, acrylic). This makes it suitable for diverse applications, from aerospace components to luxury goods. -

Efficiency and Productivity:

Automation reduces human error, increases production speed, and minimizes downtime, resulting in greater efficiency. -

Repeatability and Consistency:

Once a program is finalized, CNC machining ensures uniformity and consistency, whether for prototypes or mass production. -

Relatively Reduced Labor Costs (in High-Volume Production):

While setup requires skilled operators, automated processes reduce the need for ongoing manual labor, leading to lower per-unit labor costs in high-volume production.

Which industries commonly use CNC machines?

CNC machines are integral to a wide range of industries, including:

-

Automotive:

Used for manufacturing engine blocks, cylinder heads, transmission gears, custom body panels, and molds. -

Aerospace:

Produces high-performance, lightweight, and durable components for aircraft and spacecraft, such as structural parts, turbine blades, landing gear components, and satellite parts. -

Electronics:

Creates precise enclosures for smartphones and laptops, heat sinks for CPUs, connectors, and intricate internal components for circuit boards. -

Medical:

Manufactures implants like hip and knee replacements, surgical tools, prosthetics, and medical devices that require strict precision and biocompatibility. -

Jewelry and Fashion:

Produces intricate designs for rings and necklaces, custom hardware for handbags and belts, casting molds for jewelry, and high-end finishes for watches and luxury accessories. -

Energy:

Develops components for power generation systems, including turbine blades for wind turbines, valves for oil and gas pipelines, and components for solar panels. -

Tool and Die Making:

Creates molds, dies, and tools used in injection molding, casting, and other manufacturing processes.