Have you ever wondered how manufacturers can trace a single part back to its source, production details, or even the person who operated the machine? It’s like having a detailed diary for every component you make. That’s where traceability comes into play, and let me tell you, in today’s manufacturing world, it’s not just a nice-to-have; it’s a must.

The problem is, maintaining this level of detail across every stage of production and the supply chain can feel overwhelming. You’ve got raw materials, machining parameters, quality checks, logistics—the list goes on. If you’re not careful, it’s easy for data to slip through the cracks, leaving you vulnerable to recalls, compliance issues, or worse, a dent in your reputation.

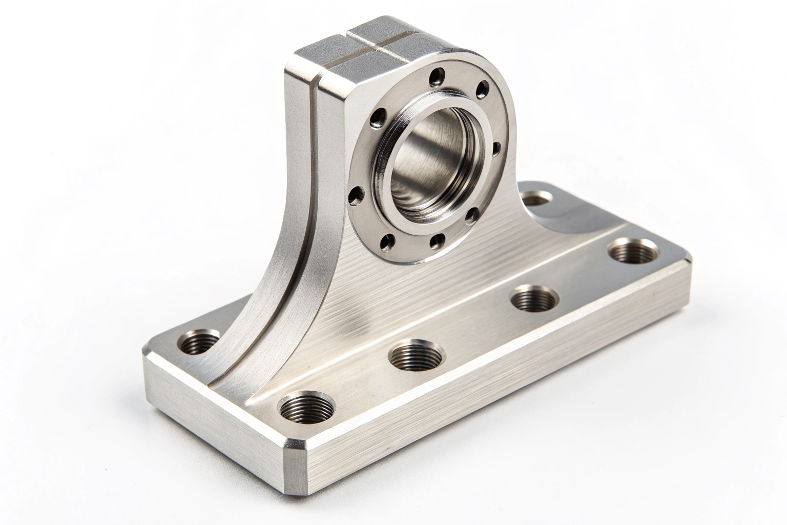

But here’s the good news: CNC machining has your back. With its precision, automation, and digital capabilities, CNC machining doesn’t just create high-quality parts; it also makes keeping track of every detail a breeze. In this post, we’ll dive into how CNC machining helps you achieve that coveted traceability. Trust me, once you see how it all comes together, you’ll wonder how manufacturing ever worked without it.

Quick Answer:

CNC machining helps achieve traceability by combining precision, automation, and digital capabilities to track every stage of a product’s lifecycle. Key methods include:

- Direct Part Marking (DPM): Unique identifiers like serial numbers, QR codes, or data matrix codes are permanently engraved on parts using CNC techniques like laser marking, engraving, or dot peening.

- Data Integration: CNC machines integrate seamlessly with systems like MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning), and PLM (Product Lifecycle Management) to store and link production data.

- Digital Twin Technology: Virtual models of CNC machines simulate and document manufacturing processes, ensuring traceability of modifications and validations.

- Automated Data Capture: Barcode scanners, RFID tags, and sensors track part movement and machining parameters, creating a comprehensive digital record.

What is Traceability and Why is it Important?

-

Definition of Traceability in Manufacturing:

Traceability in manufacturing refers to the ability to track a product's complete history, location, and application throughout the entire supply chain, from raw materials to the end consumer. It involves documenting and recording information at each stage of the product's lifecycle, creating a comprehensive digital or physical trail. This trail can include details about:- The origin of raw materials.

- Manufacturing processes and parameters.

- Quality control checks and inspections.

- Distribution channels and logistics.

- The final destination or end-user.

-

Significance of Traceability:

Traceability is more than just a record-keeping exercise; it is a cornerstone of modern manufacturing that ensures product quality, safety, regulatory compliance, and supply chain efficiency. Below are the key benefits of traceability:

Quality Control and Defect Tracking

- Root Cause Identification: Traceability enables manufacturers to pinpoint the exact source of defects by tracing a faulty product back through its production history. This includes identifying issues in:

- Raw material batches.

- Machine settings and calibrations.

- Operator actions or environmental conditions during production.

- Targeted Corrective Actions: By understanding the root cause, manufacturers can implement precise corrective measures, such as replacing a worn tool or recalibrating a machine. This leads to:

- Improved product quality.

- Reduced scrap rates.

- Enhanced manufacturing efficiency.

- Example: If a batch of machined parts shows dimensional inconsistencies, traceability can help identify whether the issue arose from a defective material batch, incorrect tooling, or improper machining parameters.

Regulatory Compliance

- Industry-Specific Standards: Many sectors, such as aerospace, medical devices, and automotive, require strict traceability to ensure safety and accountability. Examples include:

- The FDA's Unique Device Identification (UDI) system for medical devices, which mandates unique identifiers for supply chain tracking.

- The AS9100 aerospace standard, which emphasizes rigorous traceability to guarantee the integrity of aircraft components.

- Documentation for Audits: Traceability systems ensure that all necessary documentation is available for regulatory reviews, reducing the risk of non-compliance penalties.

- Market Access: Compliance with traceability regulations is often mandatory to operate in global markets.

Supply Chain Transparency

- Stakeholder Accountability: Traceability provides suppliers, manufacturers, distributors, and consumers with access to relevant product data, fostering trust and collaboration.

- Informed Decision-Making: Transparency allows consumers to verify product origins, manufacturing practices, and environmental impact, empowering them to make educated purchasing decisions.

- Example: A QR code on a product's packaging might provide consumers with detailed information about its source, the manufacturing process, and sustainability efforts.

Product Recall Management

- Efficient Recall Execution: In case of product defects or safety concerns, traceability systems allow companies to:

- Quickly identify affected batches or lots.

- Minimize the number of products involved in the recall.

- Streamline the retrieval process.

- Cost and Reputation Management: By limiting the scope of recalls, companies save money, protect their brand image, and reduce customer dissatisfaction.

- Example: A robust traceability system can ensure that only a specific faulty batch of components is recalled, avoiding unnecessary recalls of unaffected products.

Counterfeit Prevention

- Unique Identifiers: By assigning secure identifiers such as serial numbers, QR codes, or RFID tags to products, traceability helps verify authenticity and detect counterfeit goods.

- Supply Chain Integrity: Traceability systems track the movement of products, reducing the risk of counterfeit items entering the supply chain.

- Consumer Trust: Technologies like secure serialization empower consumers to verify product authenticity through apps or online platforms.

- Example: Luxury brands and high-value component manufacturers use track-and-trace systems to protect their products and ensure consumer safety.

Improved Inventory Management

- Real-Time Visibility: Traceability systems provide accurate, up-to-date information about inventory levels and product movement.

- Optimized Stock Levels: Companies can avoid overstocking or stockouts, ensuring efficient inventory turnover.

- Reduced Waste: Traceability minimizes losses from expired or obsolete products by enabling better forecasting and demand planning.

- Profitability Enhancement: Efficient inventory management contributes to cost savings and increased operational efficiency.

The Role of CNC Machining in Traceability

-

How CNC Machining Inherently Supports Traceability:

CNC (Computer Numerical Control) machining plays a pivotal role in enabling and enhancing traceability in modern manufacturing. Unlike traditional machining methods, CNC machining's inherent digital nature and precise control capabilities make it ideally suited for collecting, storing, and utilizing data for traceability purposes.

Digital Control and Automation

- CNC machines operate based on digital instructions (G-code), which precisely dictate every movement of the cutting tool. This ensures accurate control over the machining process and allows for detailed data collection, including:

- Tool Paths and Cutting Parameters: Information such as spindle speed, feed rate, depth of cut, and tool changes is digitally recorded and linked to specific parts or production batches.

- Machine Operating Time: The exact duration of each machining operation is tracked, providing insights into production efficiency and deviations from standard processing times.

- Machine Status and Alarms: Any machine malfunctions, tool wear, or anomalies are logged, aiding in troubleshooting and quality control.

Integration with CAD/CAM Systems

- CNC machining integrates seamlessly with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems, creating a continuous digital thread from design to production:

- CAD Models: The original design data serves as the foundation for all manufacturing processes, with any changes documented for traceability.

- CAM Programs: These generate the G-code that controls CNC machines, containing detailed process information linked to individual parts.

- Simulation and Verification: Simulations of machining processes verify tool paths and identify potential issues, with results recorded to enhance traceability.

Direct Part Marking (DPM)

- CNC machines can perform direct part marking, an essential traceability feature. Techniques such as engraving, laser marking, or dot peening allow for permanent marking of parts with unique identifiers (e.g., serial numbers, QR codes, data matrix codes). This ensures:

- Each part can be uniquely identified and traced throughout its lifecycle.

- Resistance to wear and harsh environments, maintaining the integrity of the traceability data.

Data Connectivity and Integration

- Modern CNC machines are designed for integration with advanced data management systems:

- Manufacturing Execution Systems (MES): Collect real-time shop floor data, including CNC performance metrics, for production monitoring and traceability.

- Enterprise Resource Planning (ERP) Systems: Manage overall business operations such as inventory and supply chain management, enabling end-to-end traceability.

- Product Lifecycle Management (PLM) Systems: Maintain comprehensive product data across its lifecycle, from design to end-of-life, enhancing traceability and documentation.

-

Alignment of CNC Machining with Digital Manufacturing:

CNC machining is a cornerstone of digital manufacturing, which leverages digital technologies to optimize processes and enhance traceability. This alignment includes the following elements:

Digital Thread

- The seamless integration of data across systems (CAD, CAM, CNC, MES, ERP, PLM) creates a unified "digital thread" that connects every stage of the product lifecycle. This thread:

- Facilitates comprehensive traceability.

- Provides instant access to design, manufacturing, and quality data for audits or troubleshooting.

Data-Driven Decision Making

- The vast amount of data generated by CNC machines supports:

- Trend Analysis: Identifying patterns to optimize production processes.

- Quality Improvement: Pinpointing factors that affect product performance and consistency.

- Process Optimization: Using data to enhance efficiency and reduce waste.

Automation and Integration

- CNC machining is highly automated and can be integrated with:

- Robotic Material Handling: Automates part movement to streamline production.

- Automated Inspection Systems: Reduces manual data entry and error rates while ensuring real-time quality control.

Industry 4.0 and IIoT (Industrial Internet of Things)

- CNC machines are increasingly connected to IIoT platforms, enabling:

- Real-Time Monitoring: Immediate visibility into machine performance and production metrics.

- Remote Control: Operators can adjust processes remotely, enhancing responsiveness.

- Predictive Maintenance: Analyzing data to predict and prevent equipment failures, reducing downtime and quality issues.

-

The Significance of CNC Machining in Traceability:

CNC machining’s digital nature, precision, and automation make it indispensable for achieving robust traceability in manufacturing. By integrating with advanced technologies and aligning with digital manufacturing trends, CNC machining:- Ensures consistent product quality.

- Enhances transparency across the supply chain.

- Reduces risks associated with recalls, compliance, and counterfeit products.

- Meets the demands of modern, data-driven manufacturing environments.

How CNC Machining Enables Traceability

CNC (Computer Numerical Control) machining plays a crucial role in modern manufacturing, not only for its precision and efficiency but also for its ability to enable robust traceability. Traceability, defined as the ability to track a product's history, location, and application throughout its lifecycle, is essential for quality control, regulatory compliance, and supply chain management. CNC machining facilitates traceability through several key mechanisms:

Part Marking and Identification

CNC machining enables Direct Part Marking (DPM), a critical method for applying permanent, unique identifiers directly onto parts. This ensures that each part can be traced back to its origin, manufacturing process, and other relevant data.

-

DPM Methods Used in CNC Machining:

- Engraving: CNC machines use cutting tools to carve markings into the part's surface. This method is durable and suitable for various materials, creating deep, permanent marks resistant to wear and tear.

- Laser Marking: A focused laser beam creates markings through processes like ablation, discoloration, or etching. Laser marking offers speed, precision, and flexibility, making it ideal for complex codes or intricate designs. Different lasers, such as fiber, CO₂, or UV lasers, are used depending on the material.

- Dot Peening/Micro-Percussion: This method uses a vibrating stylus to create small indentations that form characters, codes, or logos. It is cost-effective, versatile, and particularly effective for hardened metals and rough surfaces.

-

Advantages of DPM:

- Durability: Markings withstand abrasion, chemicals, and extreme environmental conditions.

- Permanence: Since the marks are integral to the part, they cannot be easily removed or altered.

- Resistance to Harsh Environments: DPM is ideal for industries like aerospace, automotive, and medical devices where parts endure demanding conditions.

Data Integration with CNC Machines

Modern CNC machines are designed to integrate seamlessly with enterprise systems, enabling efficient data collection, storage, and accessibility.

-

System Integration:

- Manufacturing Execution Systems (MES): Provide real-time tracking and control of the manufacturing process, capturing data on performance and output.

- Enterprise Resource Planning (ERP) Systems: Manage resources such as inventory, financials, and supply chain data, creating a holistic view of manufacturing operations.

- Product Lifecycle Management (PLM) Systems: Track all data related to a product's lifecycle, from design to disposal, ensuring comprehensive traceability.

-

Real-Time Data Collection:

- Machine Settings: Data on spindle speed, feed rate, and tool usage ensures consistent quality and aids in process optimization.

- Operator Information: Tracks operator involvement, helping identify training needs or sources of errors.

- Date and Time of Manufacturing: Provides crucial information for tracking production schedules and bottlenecks.

- Raw Material Batch Numbers: Links finished parts to their raw material batches, allowing for tracing material-related issues.

- Inspection Results: Integrates quality control data with production records to create a comprehensive traceability framework.

-

Data Storage and Access:

- Collected data is stored in centralized databases and can be accessed for audits, failure analysis, or process improvement initiatives.

Digital Twins and Simulation

The digital twin is a virtual representation of a physical CNC machine, process, or entire manufacturing system. It mirrors the real-world counterpart, enabling advanced traceability capabilities.

-

Simulating Manufacturing Processes and Tracking Changes:

- Digital twins allow manufacturers to test machining scenarios, optimize parameters, and validate tool paths before implementing changes on physical machines.

- Process modifications in the digital twin are tracked and recorded, ensuring traceability of adjustments.

-

Using Simulation Data for Validation:

- Simulation data validates manufacturing processes, ensuring part quality and compliance with specifications. It can also be used for operator training and troubleshooting production issues.

Automated Data Capture and Tracking

CNC machining workflows incorporate automated technologies to enhance data capture and tracking.

-

Automated Technologies:

- Barcode Scanners: Capture data quickly and accurately from barcodes on parts, tools, or materials.

- RFID Tags: Provide wireless tracking of parts and tools, even in harsh environments.

- Sensors and Data Acquisition Devices: Collect real-time data on machine performance, environmental conditions, and other parameters.

-

Linking Data to Unique Identifiers:

- Data captured by these technologies is linked to unique part identifiers created through DPM. This linkage creates a comprehensive digital record of the part’s journey through the manufacturing process, including:

- Material origin.

- Machining parameters.

- Inspection results.

- Distribution and shipping details.

Key Features of CNC Machining That Enhance Traceability

CNC machining offers unparalleled capabilities for enhancing traceability, leveraging data-driven production and integration with Industry 4.0 technologies. These features go beyond basic part marking and data collection, enabling manufacturers to create comprehensive, interconnected traceability systems that span the entire production lifecycle.

1. Data-Driven Production

CNC machining inherently generates large volumes of detailed data during the production process. This data, when properly managed, becomes a powerful tool for ensuring traceability, allowing manufacturers to track every aspect of a product’s creation.

-

CNC Machine Logs:

- Program Execution Data: Logs contain the specific CNC program used for each part, including program name, revision number, and execution time, ensuring that machining instructions are fully documented.

- Tool Usage Data: Detailed records of tool types, tool numbers, cutting parameters (speed, feed, depth of cut), and tool wear provide insights into tool performance and potential issues.

- Machine Status Data: Logs include spindle speeds, axis positions, coolant status, and error messages or alarms, helping diagnose problems and monitor machine performance.

- Timestamped Events: Each significant event in the machining process is timestamped, providing a precise chronological record of operations.

- Operator Interactions: Logs of operator actions, such as program changes, overrides, or manual interventions, reveal how operator inputs affect the process.

-

Digital Records:

- Centralized Data Storage: All operational data is stored in a centralized database, ensuring easy access for authorized personnel.

- Data Integrity: Digital records minimize errors and the risks of data loss associated with paper-based systems.

- Data Analysis and Reporting: Collected data can be analyzed to identify trends, patterns, and areas for improvement, with reports generated to track KPIs and demonstrate regulatory compliance.

- Long-Term Archiving: Historical data can be archived for future reference, aiding audits and long-term planning.

- Integration with Quality Management Systems (QMS): CNC data integrates with QMS to automate quality control processes, ensuring compliance with industry standards.

By leveraging CNC machine logs and digital records, manufacturers create a robust audit trail for each part, detailing its entire manufacturing history from raw material to finished product. This audit trail is invaluable for quality control, troubleshooting, and process improvement.

2. Integration with Industry 4.0

The advent of Industry 4.0 has transformed CNC machining into a connected, data-rich process that supports real-time traceability and enhanced manufacturing efficiency.

-

CNC Connectivity with IoT:

- Real-Time Monitoring: IoT-enabled CNC machines collect data on parameters such as vibration, temperature, and power consumption, providing real-time insights into machine performance. This enables early detection of potential problems and prevents costly downtime.

- Predictive Maintenance: By analyzing sensor data, manufacturers can predict when maintenance will be needed, optimizing schedules and minimizing disruptions.

- Remote Access and Control: IoT connectivity allows operators to remotely access and control CNC machines, enabling diagnostics, troubleshooting, and program updates from anywhere.

-

Integration with Other Smart Technologies:

- Cloud Computing: Scalable, secure cloud platforms store CNC data, enabling easy access, sharing, and collaboration across the supply chain.

- Big Data Analytics: Advanced analytics tools process vast amounts of CNC data, identifying trends, patterns, and correlations that lead to process optimization, improved quality, and better decision-making.

- Cyber-Physical Systems (CPS): CPS create a seamless integration between physical CNC machines and digital systems, enabling real-time monitoring, control, and optimization of the production process.

- Digital Thread: This concept connects all digital data related to a product throughout its lifecycle. CNC data forms a critical part of the digital thread, providing a detailed record of every stage of manufacturing, from design to production to delivery.

Benefits of Key CNC Features for Traceability:

- Enhanced Supply Chain Visibility: Real-time data sharing provides all stakeholders with a transparent view of the production process.

- Improved Quality Control: Comprehensive data records ensure consistent quality and facilitate rapid root cause analysis in case of defects.

- Streamlined Compliance: Detailed logs and records simplify audits and ensure adherence to industry regulations.

- Optimized Maintenance: Predictive maintenance reduces downtime, ensuring consistent traceability and operational efficiency.

Examples of Traceability in CNC Machining Applications

Traceability in CNC machining goes beyond theoretical concepts, finding practical applications across industries with diverse and stringent requirements.

Aerospace Industry

The aerospace industry demands exceptional traceability due to the critical nature of its components, where even minor failures can have catastrophic consequences.

-

Tracking Critical Components for Aircraft Safety:

- CNC machining is used to produce high-precision components like turbine blades, landing gear parts, and structural elements.

- Each component is meticulously tracked throughout its lifecycle, encompassing raw material origins, machining processes, inspections, and maintenance records.

-

Meeting Stringent Regulatory Requirements:

- Compliance with standards such as AS9100 mandates robust traceability systems.

- Traceability ensures that every aerospace component meets rigorous quality and safety benchmarks.

-

Managing Complex Supply Chains:

- Aerospace supply chains involve multiple suppliers and subcontractors.

- Traceability systems ensure that each part can be traced back to its origin, regardless of its production location.

-

Facilitating Failure Investigations:

- In case of an incident, traceability data helps identify root causes, aiding in corrective measures and preventing recurrence.

Medical Device Manufacturing

In medical device manufacturing, traceability is critical for ensuring patient safety and meeting strict regulatory standards.

-

Ensuring Regulatory Compliance and Patient Safety:

- Regulations like FDA 21 CFR Part 820 and ISO 13485 require comprehensive traceability systems.

- CNC-machined components for implants, surgical instruments, and diagnostic devices are tracked to ensure compliance.

-

Managing Product Recalls:

- Robust traceability allows manufacturers to quickly identify and isolate defective products, minimizing patient risk during recalls.

-

Tracking Device Usage and Performance:

- Traceability systems monitor device usage and performance in clinical settings, providing data for product improvement and post-market surveillance.

-

Preventing Counterfeit Products:

- Unique identifiers on medical devices prevent counterfeit distribution, safeguarding patient safety and maintaining brand integrity.

Automotive Industry

The automotive industry benefits significantly from traceability, particularly in managing supply chains and addressing recalls.

-

Managing Complex Supply Chains and Tracking Parts for Recalls:

- Modern vehicles comprise thousands of CNC-machined parts sourced globally.

- Traceability enables automakers to trace each part back to its origin, streamlining recall management in case of defects.

-

Ensuring Quality and Consistency:

- Traceability ensures all parts meet quality standards, resulting in reliable vehicle performance and durability.

-

Optimizing Manufacturing Processes:

- Traceability data provides insights for process improvement, boosting efficiency and reducing costs.

-

Meeting Automotive Industry Standards:

- Compliance with standards like IATF 16949 is supported by traceability systems, emphasizing quality management and transparency.

Benefits of Traceability for CNC Machining Customers

Traceability in CNC machining delivers significant advantages for customers, enhancing product quality, operational efficiency, and compliance.

-

Improved Product Quality and Reliability:

- Traceability systems identify and address quality issues early, ensuring higher-quality and more reliable products.

-

Reduced Risk of Recalls and Liability:

- Quick identification and isolation of defective batches minimize the financial and reputational impact of recalls.

-

Enhanced Customer Satisfaction and Trust:

- Transparent traceability demonstrates a commitment to quality and safety, building trust and loyalty among customers.

-

Increased Efficiency and Cost Savings:

- Streamlined processes, waste reduction, and improved inventory management lead to significant cost efficiencies.

-

Better Compliance with Industry Regulations:

- Traceability simplifies audits and ensures adherence to regulatory requirements, avoiding penalties and ensuring market access.

Challenges in Implementing Traceability Through CNC Machining

While traceability offers immense benefits, its implementation presents certain challenges.

Technology Integration Costs

-

Investment in Equipment:

- Advanced marking systems, such as laser engravers or dot peening machines, are essential for Direct Part Marking (DPM).

-

Data Collection and Storage Systems:

- Implementing Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), or Product Lifecycle Management (PLM) systems requires significant financial investment.

-

Connectivity Infrastructure:

- Reliable networks for seamless communication between machines and systems are necessary.

-

Software Integration:

- Customization and integration of software platforms to ensure smooth data flow involve additional costs.

-

Long-Term Costs:

- Maintenance, software updates, and scalability considerations add to ongoing operational expenses.

Training and Adaptation

-

Employee Training:

- Operators need training to handle new technologies, follow updated procedures, and interpret traceability data effectively.

-

Change Management:

- Transitioning to traceability-focused workflows can face resistance. Clear communication, leadership support, and addressing concerns are vital for smooth adaptation.

-

Data Management and Analysis Skills:

- Employees must acquire skills to analyze and interpret large datasets generated by traceability systems, ensuring meaningful insights and actions.

Future Trends: CNC Machining and Advanced Traceability Technologies

The future of traceability in CNC machining is being shaped by cutting-edge technologies such as artificial intelligence (AI) and blockchain. These advancements are transforming how data is monitored, analyzed, and secured, creating more robust and transparent traceability systems. Below, we explore the impact of these technologies on CNC machining.

1. AI-Driven Monitoring

Artificial intelligence is revolutionizing CNC machining by enabling smarter, more proactive traceability systems. AI applications in monitoring, analysis, and optimization enhance operational efficiency and product quality.

-

Predictive Maintenance and Quality Control:

- AI algorithms analyze vast amounts of real-time data from CNC machines and sensors to predict potential machine failures or quality issues.

- Proactive maintenance reduces downtime and ensures production consistency, while early detection of defects minimizes waste and rework.

-

Anomaly Detection:

- AI can identify deviations in machine behavior or product characteristics that signal potential problems.

- Early intervention prevents the continued production of defective parts, saving time and resources.

-

Process Optimization:

- By analyzing machining parameters (e.g., cutting speed, feed rate, depth of cut), AI can suggest improvements to enhance efficiency and quality.

- Continuous optimization ensures consistent product performance and cost savings.

-

Automated Inspection:

- AI-powered vision systems automate quality inspections, identifying defects with higher accuracy and consistency than manual methods.

- Real-time inspection data is directly integrated into traceability systems.

-

Enhanced Traceability Data Analysis:

-

AI uncovers patterns, trends, and correlations in traceability data that are difficult to detect manually.

-

These insights enable manufacturers to refine processes, improve quality, and enhance supply chain efficiency.

-

Root Cause Analysis: AI quickly identifies the root causes of quality issues by analyzing production data and identifying contributing factors.

-

Supply Chain Optimization: AI helps identify bottlenecks, optimize logistics, and improve supply chain transparency.

-

-

AI-Powered Digital Twins:

- AI enhances digital twins—virtual replicas of physical CNC systems—by enabling dynamic simulations and predictions.

- Real-Time Simulation: AI allows manufacturers to simulate and optimize production processes in real time.

- Predictive Maintenance: AI predicts maintenance needs within the digital twin, enabling proactive planning and reducing downtime.

By leveraging AI, CNC machining evolves into a smarter and more proactive environment, ensuring traceability while improving operational efficiency and product quality.

2. Blockchain for Data Integrity

Blockchain technology, renowned for its use in cryptocurrencies, is becoming a powerful tool for ensuring the integrity, security, and transparency of traceability data in CNC machining.

-

Immutable Records:

- Blockchain creates a decentralized, tamper-proof ledger where each transaction or data entry is permanently recorded.

- Data integrity is guaranteed, as entries cannot be altered or deleted once added to the blockchain.

-

Tamper-Proof Traceability Data:

- Blockchain ensures traceability data remains secure and trustworthy, eliminating the risk of data manipulation.

- This is especially critical for industries like aerospace and medical devices, where regulatory compliance is non-negotiable.

-

Secure Data Sharing:

- Blockchain facilitates secure, direct data sharing between supply chain participants without intermediaries.

- Stakeholders can access the same data, ensuring transparency and reducing disputes.

-

Enhanced Transparency:

- Every transaction is auditable, creating a comprehensive and transparent history of each CNC-machined product.

- Customers and regulators can verify the authenticity and compliance of parts by accessing blockchain records.

-

Decentralized Data Management:

- Blockchain’s decentralized nature reduces the risk of data loss or breaches:

- Reduced Risk of Data Loss: Data is distributed across multiple nodes, preventing single points of failure.

- Increased Security: Decentralization makes blockchain systems highly resistant to cyberattacks.

-

Smart Contracts for Automated Traceability:

- Smart contracts are self-executing agreements that automate various aspects of traceability:

- Automated Data Entry: Data is recorded on the blockchain automatically when events like part production or shipping occur.

- Automated Verification: Smart contracts verify the authenticity of parts and materials by cross-referencing blockchain records.

- Automated Compliance: Smart contracts ensure compliance by validating that all required traceability data is recorded before proceeding to the next step.

Conclusion

So, after reading through all of this, I hope you’re starting to see how traceability and CNC machining are a perfect match. From ensuring safety in aerospace to meeting strict regulations in medical devices and managing massive automotive supply chains, CNC machining truly empowers manufacturers to track every single detail of their processes. And let’s be honest, in today’s world, where quality and accountability are non-negotiable, that’s a game-changer.

The future is even more exciting. Technologies like AI and blockchain are not just buzzwords—they’re revolutionizing how we think about manufacturing and traceability. Imagine a system where your CNC machines predict their own maintenance needs, or a blockchain ledger that guarantees your product data is untouchable. These advancements are here to make manufacturing smarter, faster, and more reliable than ever.

If you’re as passionate about precision and reliability as I am, you know that having the right CNC machining partner is crucial. At PROMACHINED, we specialize in precision CNC machining and traceability solutions tailored to your needs. Whether it’s a small project or a large-scale production, we’re here to help you achieve top-notch quality and efficiency.

Curious to learn more? Visit us at www.promachined.com and let’s chat about how we can make traceability work for you. After all, isn’t it time we made manufacturing a little less complicated and a lot more reliable? Let’s get started!

FAQ

1. What are the most commonly used materials for CNC machining?

The most commonly used materials include aluminum, steel, brass, titanium, and plastics like ABS and POM. Material selection depends on factors such as strength, weight, thermal resistance, and machinability. Easier-to-machine materials often reduce costs and improve surface finishes, making machinability a key consideration.

2. CNC machining vs. 3D printing: Which is better for precision?

CNC machining generally offers higher precision, with tolerances as tight as ±0.01 mm, compared to typical 3D printing tolerances. However, advanced 3D printing technologies like stereolithography (SLA) or selective laser melting (SLM) can achieve tighter tolerances than basic FDM (fused deposition modeling). CNC is ideal for high-precision, high-strength components, while 3D printing excels in rapid prototyping and intricate geometries.

3. What impacts the cost of CNC machining?

Key cost factors include material selection, part complexity, machining time, tolerances, order volume, and surface finish requirements. More intricate designs, tighter tolerances, and finer finishes often lead to higher costs.

4. How can I ensure CNC machining accuracy?

To ensure accuracy, select a reliable CNC machining provider, specify clear tolerances, use precision tools, and ensure proper workholding during machining. Quality checks like coordinate measuring machines (CMM) and real-time monitoring are also crucial for maintaining precision.

5. Which industries rely on CNC machining?

CNC machining is widely used in aerospace, automotive, medical devices, electronics, and industrial machinery. It’s essential for applications requiring precision, durability, and efficiency in producing high-performance components.