Sourcing CNC parts from China can be highly advantageous, offering cost-effective solutions and access to a wide range of suppliers. However, the process comes with its own set of challenges, such as communication barriers, quality control issues, and complexities in shipping logistics.

To successfully source CNC parts from China, follow these precautions:

- Verify Suppliers: Use platforms like Alibaba and Global Sources, check ISO certifications, and attend trade shows like the Canton Fair.

- Communicate Clearly: Provide detailed CAD files, specify tolerances and finishes, and use formal contracts.

- Ensure Quality: Conduct in-process inspections, pre-shipment checks, and define acceptance criteria (e.g., AQL).

- Plan Logistics: Choose suitable Incoterms (FOB, CIF, DDP), work with reliable freight forwarders, and ensure proper packaging.

- Secure Payments: Use Letters of Credit (L/C), escrow services, and monitor exchange rates.

- Build Trust: Maintain communication, visit suppliers, and ensure timely payments.

Finding Reliable CNC Part Suppliers in China

Sourcing CNC parts from China offers significant cost advantages and access to a vast manufacturing ecosystem. However, navigating this landscape requires careful due diligence to ensure you partner with reliable and capable suppliers. This comprehensive guide combines strategies to find and verify suitable CNC part manufacturers using both online and offline methods.

Online Platforms: Expanding Your Search

Online B2B platforms provide an efficient way to connect with numerous suppliers. However, exercising caution and thoroughly vetting potential partners is crucial to avoid risks.

-

Alibaba.com:

As the world's largest B2B marketplace, Alibaba hosts a massive directory of Chinese manufacturers, including a substantial number specializing in CNC machining. Key tips for leveraging Alibaba:- Gold Supplier Verification: Look for the "Gold Supplier" badge, which indicates on-site verification by Alibaba or a third-party inspection agency. However, this badge is not a guarantee of quality; additional checks are necessary.

- Trade Assurance: Use Alibaba's Trade Assurance service for payment protection in case of disputes, non-delivery, or quality issues.

- Supplier Profiles and Reviews: Carefully examine supplier profiles, focusing on years in business, product range, and customer feedback. Avoid suppliers with limited or negative reviews.

- Requesting Documentation: Ask suppliers directly for business licenses, ISO certifications (e.g., ISO 9001 for quality management), and other relevant credentials. When possible, verify these documents through official channels.

-

GlobalSources.com:

Known for connecting buyers with verified and export-oriented suppliers, Global Sources offers an additional layer of reliability:- Verified Suppliers: Suppliers on this platform undergo rigorous verification, ensuring higher quality.

- Focus on Export Experience: Many suppliers listed have substantial experience with international trade, simplifying logistics and communication.

- Trade Shows: Global Sources also hosts trade events, enabling in-person connections.

-

Industry-Specific B2B Platforms:

Explore niche platforms specializing in manufacturing, metalworking, or CNC-specific applications. Examples include Made-in-China.com and MachiningCloud. These platforms often feature suppliers with specialized expertise, offering targeted solutions.

Trade Shows: Building Face-to-Face Connections

Attending trade shows provides invaluable opportunities to meet suppliers in person, assess their capabilities, and establish trust.

-

Canton Fair (China Import and Export Fair):

This biannual trade show is one of the largest in the world, showcasing a wide range of products, including machinery and industrial equipment. Highlights include:- Direct Interaction: Face-to-face meetings facilitate clear communication and immediate feedback.

- Product Inspection: You can physically examine samples and discuss technical requirements with potential suppliers.

-

Other Relevant Trade Shows:

Consider attending specialized exhibitions, such as:- China International Industry Fair (CIIF): Focuses on advanced manufacturing technologies and solutions.

- Regional Manufacturing Expos: Smaller events that highlight local expertise in CNC machining and related fields.

These trade shows provide insights into industry trends and allow for networking with high-quality manufacturers.

Referrals and Recommendations: Leveraging Your Network

Personal recommendations from trusted sources, such as colleagues, industry peers, or businesses with experience sourcing from China, are invaluable for reducing risks.

- Reduced Risk: Referred suppliers are often pre-vetted, lowering the likelihood of encountering unreliable manufacturers.

- Streamlined Vetting: Recommendations can save time by providing firsthand information on supplier performance, communication, and product quality.

Supplier Verification: Essential Due Diligence

Verification is a critical step to ensure that the supplier is legitimate, capable, and aligned with your requirements.

-

Business Licenses and Certifications:

- Verify the supplier’s legal registration and confirm relevant certifications, such as:

- ISO 9001: Quality Management System certification.

- ISO 14001: Environmental Management System certification.

- Industry-Specific Standards: Certifications for specific sectors, such as ISO/TS 16949 for automotive parts.

- Authenticate certifications with the issuing bodies when possible.

-

Factory Audits:

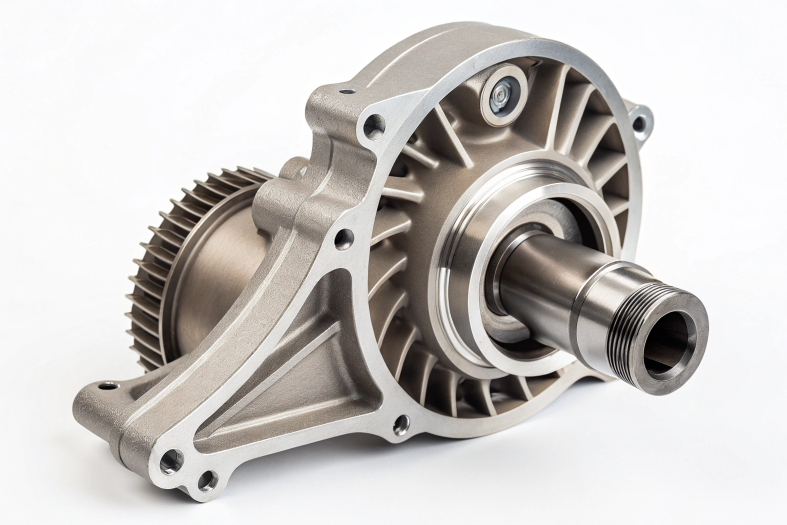

- On-Site Audits: Visiting the factory provides the most comprehensive assessment of production capabilities, equipment, and quality control processes.

- Virtual Audits: For cost-effective alternatives, use video conferencing to inspect facilities and review documentation remotely.

-

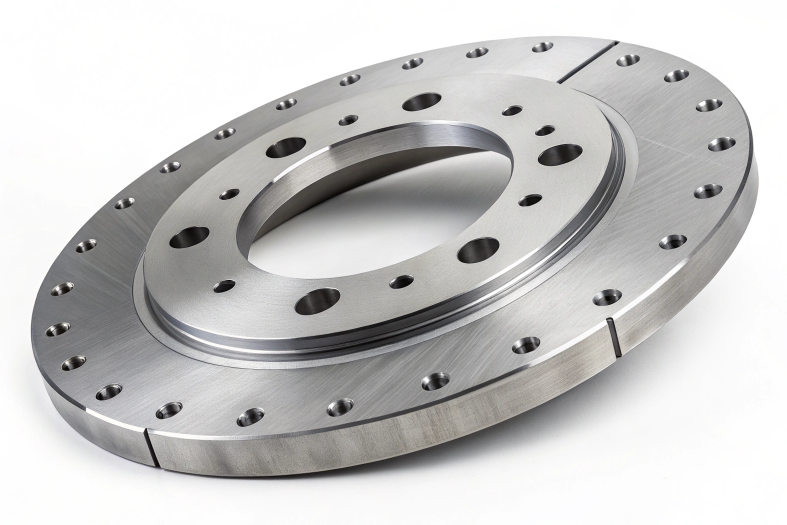

Sample Requests and Testing:

- Request samples to evaluate the supplier’s ability to meet technical requirements.

- Test for critical parameters, including dimensional accuracy, material properties, and surface finish.

- Use these evaluations to gauge consistency and quality.

-

Financial Stability Check:

- Assess the supplier’s financial health through credit reports or financial statements to ensure long-term viability.

Clear Communication and Specifications: Laying the Foundation for Success

Effective communication and precise specifications are paramount when sourcing CNC parts from China. Ambiguity or misunderstandings can lead to costly errors, delays, and disputes. This section emphasizes the importance of clear communication and provides guidelines for creating comprehensive specifications.

Detailed Drawings and Specifications: The Blueprint for Manufacturing

Providing accurate and detailed technical documentation is crucial for ensuring the supplier understands your exact requirements.

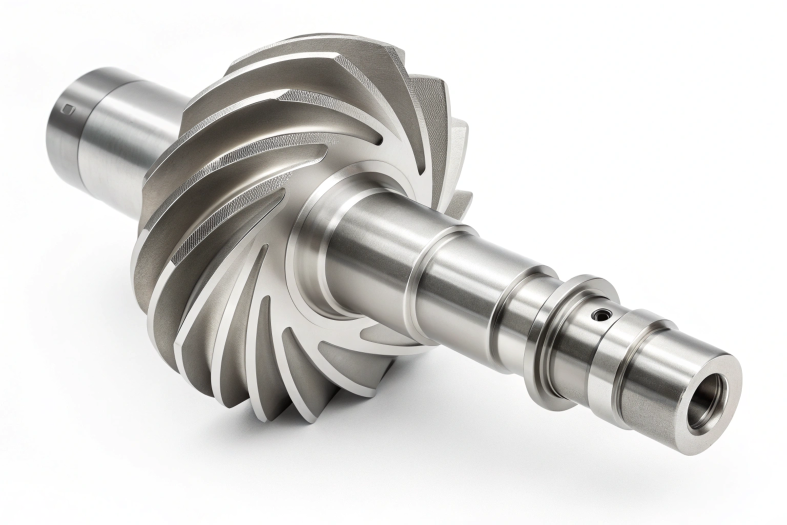

- CAD Files (STEP, DWG, DXF): Supply native CAD files in universally compatible formats such as STEP (STP) or IGES (IGS) for 3D models, and DWG or DXF for 2D drawings. These formats preserve geometric data and allow for accurate interpretation by CNC machines. Avoid sending only PDF or image files, as these are not suitable for direct machining.

- Dimensional Tolerances:

- Clearly specify tolerances for all critical dimensions.

- Use standard systems like ISO 2768 or ASME Y14.5, or provide custom tolerances for individual features.

- Tight tolerances increase manufacturing costs, so specify them only where functionally necessary.

- Material Specifications:

- Define the exact material grade and composition required using recognized standards (e.g., ASTM, DIN, JIS).

- If material certifications (e.g., RoHS, REACH) are required, state this clearly.

- Surface Finish Requirements:

- Specify surface finish standards (e.g., Ra for roughness).

- Choose finishes based on functional or aesthetic needs, such as anodizing or plating.

- Special Processes and Treatments:

- Specify heat treatments, coatings, or other secondary processes.

- Include details on required standards and testing protocols.

- Assembly Instructions (If Applicable):

- If the part is part of an assembly, provide instructions for tolerances, mating parts, and assembly procedures.

- Compliance and Certifications:

- Clearly state required certifications, such as FDA for medical devices or UL for electrical components.

Language and Cultural Differences: Bridging the Gap

Cross-cultural communication is vital to ensuring mutual understanding and a successful partnership.

- Clear and Concise English:

- Use plain English and avoid idiomatic expressions.

- Reiterate key points to confirm understanding.

- Technical Terminology:

- Use standard technical terms and avoid jargon unless it is common in the industry.

- Provide definitions or visual aids for complex terms.

- Written Communication:

- Prioritize email or formal documentation to create a clear record.

- Avoid relying solely on verbal agreements.

- Cultural Sensitivity:

- Respect cultural differences in communication and business etiquette.

- Be patient and avoid assuming shared knowledge.

- Professional Translation Services:

- Use professional translation services for critical technical documents to ensure accuracy.

Written Contracts and Agreements: Protecting Your Interests

A formal written contract ensures that expectations are clear and enforceable.

- Comprehensive Terms and Conditions:

- Product Specifications: Reference detailed drawings and material requirements.

- Pricing and Payment Terms: Specify agreed prices, payment schedules, and currencies.

- Delivery Timelines: Clearly define deadlines and penalties for delays.

- Quality Control Clauses: Include inspection processes, acceptance criteria, and defect handling procedures.

- Intellectual Property Rights: Protect proprietary designs and processes through confidentiality clauses.

- Dispute Resolution: Specify mediation or arbitration processes and governing laws.

- Language of the Contract:

- Use bilingual contracts when necessary, with the English version as the primary reference.

Quality Control and Inspection: Ensuring Conformance

Implementing robust quality control measures ensures parts meet your specifications and expectations.

In-Process Inspections: Preventing Defects Early

- Regular Monitoring:

- Conduct inspections at key stages of production to identify issues before they escalate.

- Clear Inspection Criteria:

- Provide the supplier with detailed instructions and tolerances for inspection.

- Documentation:

- Maintain detailed records of inspections, findings, and corrective actions.

Pre-Shipment Inspections: Verifying Quality Before Shipping

- Third-Party Inspection Services:

- Hire reputable third-party companies like SGS, Bureau Veritas, or Intertek.

- Ensure they verify quantity, quality, packaging, and labeling.

- Comprehensive Inspection:

- Inspect critical dimensions, material properties, surface finishes, and packaging.

- Inspection Report:

- Obtain a detailed report to review before approving shipment.

Acceptance Criteria (AQL): Defining Acceptable Quality Levels

- AQL Standards:

- Use ANSI/ASQ Z1.4 or ISO 2859-1 to define acceptable quality levels.

- Categorize defects as critical, major, or minor, and specify allowable thresholds.

- Clearly Defined Defects:

- Provide examples of defects and their classifications.

Handling Defects and Disputes: Establishing a Clear Resolution Process

- Written Procedures:

- Document the process for addressing defective parts.

- Return and Replacement Policy:

- Clearly define responsibilities for shipping and replacement costs.

- Communication and Documentation:

- Maintain detailed communication and records during dispute resolution.

Shipping and Logistics: Navigating the Supply Chain

Efficient and reliable shipping and logistics are crucial for receiving your CNC parts on time and in good condition. This section details key considerations for managing the shipping process.

Shipping Terms (Incoterms): Defining Responsibilities

Incoterms (International Commercial Terms) are standardized trade terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for clarifying who is responsible for costs, risks, and documentation at each stage of the shipping process.

-

FOB (Free on Board) (Named Port of Shipment):

- The seller is responsible for transporting goods to the shipping vessel and covering loading costs.

- Once the goods are loaded onto the vessel, the buyer assumes responsibility for freight, insurance, and any subsequent costs or risks.

- Best for: Buyers with established relationships with freight forwarders who prefer managing shipping themselves.

-

CIF (Cost, Insurance, and Freight) (Named Port of Destination):

- The seller covers shipping and insurance costs until the goods reach the destination port.

- Risk transfers to the buyer once the goods are loaded onto the vessel.

- Best for: Buyers seeking convenience in initial shipping arrangements but willing to handle customs and inland transportation.

-

DDP (Delivered Duty Paid) (Named Place of Destination):

- The seller handles all costs and risks, including import duties and taxes, until the goods are delivered to the buyer’s specified location.

- Best for: Buyers who prefer maximum convenience and minimal involvement in the shipping process, despite potentially higher costs.

-

Other Incoterms:

- Additional terms such as EXW (Ex Works), FCA (Free Carrier), and CFR (Cost and Freight) allocate responsibilities differently. Choose the term that aligns with your logistical capabilities and requirements.

Freight Forwarders: Streamlining Logistics

Freight forwarders are vital intermediaries that simplify the complexities of international shipping.

-

Services Offered:

- Coordinate transportation across sea, air, or land routes.

- Negotiate freight rates with carriers to ensure cost-effectiveness.

- Handle customs documentation and clearance procedures.

- Provide cargo insurance for added security.

- Track and monitor shipments throughout transit.

-

Choosing a Freight Forwarder:

- Select forwarders with a proven track record in shipping from China and handling industrial goods like CNC parts.

- Evaluate their global network, communication skills, and ability to provide end-to-end service.

- Request client references or reviews to ensure reliability.

Customs and Import Duties: Navigating Regulations

Navigating customs regulations and paying import duties accurately are critical steps in the import process.

-

Customs Brokers:

- Collaborate with licensed customs brokers who specialize in handling import regulations. Their expertise ensures compliance and prevents delays.

- Brokers can assist with:

- Preparing and submitting documentation.

- Calculating duties and taxes accurately.

- Resolving any regulatory issues.

-

Harmonized System (HS) Codes:

- Use the correct HS codes to classify your CNC parts, as these codes determine duty rates and regulatory requirements.

-

Import Documentation:

- Ensure all required documents are accurate and complete, including:

- Commercial invoices.

- Packing lists.

- Certificates of origin.

- Permits or licenses (if applicable).

Packaging and Protection: Preventing Damage During Transit

Proper packaging is essential to ensure CNC parts arrive in excellent condition, even after long-distance shipping.

-

Durable Materials:

- Use robust materials such as wooden crates, reinforced cardboard, or metal cases for heavy or delicate parts.

- Incorporate internal padding like foam, bubble wrap, or custom inserts to prevent movement and damage.

-

Secure Packaging:

- Ensure parts are immobilized and braced securely to avoid shifting during transit.

- Protect against environmental factors, such as humidity or temperature fluctuations, with appropriate packaging solutions.

-

Proper Labeling:

- Clearly label packages with handling instructions (e.g., "Fragile," "This Side Up") and accurate shipping information.

By proactively managing packaging, labeling, and handling instructions, you can minimize transit risks and ensure parts arrive undamaged.

Payment and Financial Security: Mitigating Risks

Establishing secure and efficient payment methods is vital to safeguarding your financial interests and ensuring a smooth transaction process.

Payment Methods: Balancing Security and Efficiency

-

Letter of Credit (L/C):

- A bank guarantees payment to the seller once specific conditions (e.g., correct shipping documentation) are met.

- Advantages:

- High security for both buyer and seller.

- Ideal for first-time transactions or high-value orders.

- Disadvantages:

- Involves complex paperwork and higher fees.

-

Telegraphic Transfer (T/T):

- A direct bank transfer that is faster and more commonly used.

- Risk Mitigation:

- Split payments (e.g., 30% deposit, 70% after shipment or inspection) to reduce upfront risk.

- Verify supplier bank account details to avoid fraud.

-

Escrow Services:

- Funds are held by a neutral third party until the buyer confirms goods are delivered as per agreed terms.

- Advantages:

- Higher security for new supplier relationships.

- Disadvantages:

- May incur additional service fees.

-

Online Payment Platforms:

- Platforms like PayPal or Alipay are suitable for smaller transactions but should only be used with trusted suppliers.

Currency Exchange Rates: Managing Fluctuations

Fluctuating exchange rates can significantly impact the total cost of your CNC parts.

-

Monitor Exchange Rates:

- Regularly track exchange rates to anticipate potential cost changes.

- Use online currency tools or consult financial advisors for insights.

-

Mitigation Strategies:

- Forward Contracts: Lock in a specific exchange rate for future payments to avoid unexpected increases.

- Multi-Currency Accounts: Utilize bank accounts that allow holding and paying in multiple currencies to reduce conversion fees.

Building Long-Term Relationships: Cultivating Sustainable Partnerships

Establishing strong, long-term relationships with your CNC part suppliers in China is crucial for consistent quality, reliable delivery, and competitive pricing. This section emphasizes the importance of building trust and fostering open communication.

Importance of Establishing Trust: The Foundation of Successful Collaboration

Trust is the cornerstone of any successful business relationship, especially in international trade. Building trust with your Chinese suppliers requires consistent effort and open communication.

- Regular and Proactive Communication:

- Stay in regular contact with your suppliers, even when there are no immediate orders. This demonstrates your commitment to the relationship and allows you to stay updated on their operations or any potential challenges.

- Transparent and Honest Communication:

- Be upfront about your needs, expectations, and concerns. Open communication fosters mutual understanding and helps prevent misunderstandings.

- Constructive Feedback:

- Provide balanced feedback on the supplier’s performance, addressing both strengths and areas for improvement. Frame criticisms constructively, focusing on solutions rather than assigning blame.

- Respectful and Professional Conduct:

- Maintain respect and professionalism in all interactions. Be mindful of cultural differences, such as indirect communication styles, and adapt your approach accordingly.

- Timely Payments:

- Ensure payments are made promptly to demonstrate financial reliability and reinforce trust.

- Fair Negotiation:

- Negotiate pricing and terms that are mutually beneficial. Avoid excessive price squeezing, which can hinder the supplier’s ability to maintain quality or invest in improvements.

Visiting Suppliers: Strengthening Connections and Gaining Insights

Visiting your suppliers in person, when feasible, is one of the most effective ways to strengthen relationships and gain deeper insights into their operations.

- Building Personal Connections:

- Face-to-face meetings allow for stronger rapport with key personnel, enhancing trust and collaboration.

- Gaining Firsthand Insights:

- Factory visits provide invaluable insights into the supplier’s production capabilities, equipment, quality control processes, and working conditions. This hands-on evaluation often reveals details that virtual audits cannot capture.

- Demonstrating Commitment:

- A visit shows your dedication to the partnership, emphasizing its importance and long-term value.

- Resolving Issues Effectively:

- On-site meetings facilitate more efficient communication and problem-solving for any arising issues.

Planning Your Visit:

- Schedule visits well in advance to ensure the supplier is prepared.

- Prepare a checklist of specific areas to evaluate, including production processes, certifications, and quality controls.

- Consider bringing a translator or bilingual team member if language barriers exist.

Post-Visit Actions:

- Follow up with a detailed email summarizing the key points discussed and any agreed actions, ensuring clarity and maintaining momentum.

Checklist for Purchasing CNC Parts from China: A Summary of Key Steps

This checklist summarizes the critical steps involved in sourcing CNC parts from China, serving as a quick reference for a smooth and successful procurement process.

-

[ ] Verify Supplier Credentials:

- Confirm business licenses, certifications (e.g., ISO 9001), and the supplier’s track record.

- Conduct factory audits (on-site or virtual) to evaluate production capabilities.

-

[ ] Provide Detailed Specifications:

- Supply accurate CAD files, specific tolerances, material specifications, and surface finish requirements.

- Include compliance certifications and any additional process requirements.

-

[ ] Negotiate Clear Contract Terms:

- Draft a formal written contract detailing:

- Pricing and payment schedules.

- Delivery timelines and penalties for delays.

- Quality control measures, inspection procedures, and acceptance criteria.

- Dispute resolution and intellectual property protection clauses.

-

[ ] Implement Quality Control Measures:

- Arrange in-process inspections to monitor production quality.

- Conduct pre-shipment inspections, using third-party services if necessary.

- Define clear acceptance criteria based on AQL standards.

-

[ ] Secure Appropriate Shipping Arrangements:

- Select suitable Incoterms (e.g., FOB, CIF, DDP) based on your needs.

- Work with a reliable freight forwarder and customs broker.

- Ensure proper packaging and labeling to prevent transit damage.

-

[ ] Choose a Secure Payment Method:

- Opt for secure methods such as Letters of Credit (L/C), split Telegraphic Transfers (T/T), or escrow services.

- Monitor currency exchange rates to manage fluctuations effectively.

-

[ ] Establish Regular Communication:

- Maintain open and consistent communication throughout the process, from initial inquiries to post-delivery feedback.

-

[ ] Build Long-Term Relationships:

- Focus on trust-building, providing constructive feedback, and planning in-person visits to foster collaboration.

Conclusion

Sourcing CNC parts from China presents an excellent opportunity to leverage cost efficiencies, access advanced manufacturing capabilities, and build lasting partnerships. However, this process requires careful planning, thorough due diligence, and strong communication to navigate challenges such as quality control, shipping logistics, and cultural differences.

By following the best practices outlined in this guide—ranging from verifying supplier credentials and negotiating clear contract terms to implementing robust quality control measures and fostering long-term relationships—you can significantly reduce risks and ensure a smooth procurement experience.

Approach each step of the sourcing journey with precision and attention to detail, and prioritize building trust with your suppliers. These efforts will not only enhance the quality and reliability of the CNC parts you receive but also establish a foundation for successful, long-term collaboration. With the right strategies in place, you can unlock the full potential of sourcing from China and achieve your business goals effectively.

FAQ:

What are the common problems in a CNC machine?

Common problems in CNC machines include:

- Tool Wear: Decreased tool sharpness leading to poor precision.

- Overheating: Prolonged operation causing thermal damage.

- Software Errors: Issues in CNC programming or compatibility.

- Misalignment: Incorrect calibration affecting accuracy.

- Power Supply Issues: Voltage fluctuations causing machine stops.

What is the most important rule in CNC safety?

The most important CNC safety rule is always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection. Additionally:

- Never leave the machine unattended during operation.

- Ensure emergency stops are functional.

- Follow the manufacturer's safety guidelines.

What is the right-hand rule for CNC?

The right-hand rule in CNC helps determine the coordinate system:

- Point your thumb in the direction of the X-axis (left/right).

- Point your index finger in the direction of the Y-axis (forward/backward).

- Point your middle finger in the direction of the Z-axis (up/down).

This rule ensures accurate orientation during setup and programming.

What is preventive maintenance in CNC?

Preventive maintenance in CNC involves regular, scheduled checks to avoid machine breakdowns. Key tasks include:

- Lubrication: Ensuring moving parts are properly oiled.

- Inspection: Checking belts, gears, and spindles for wear.

- Cleaning: Removing debris and ensuring coolant systems are clear.

- Calibration: Verifying machine accuracy and alignment.

- Software Updates: Keeping control systems current.

These practices improve performance, extend machine life, and reduce downtime.