Metal stamping is a manufacturing process that has become indispensable across industries. It involves shaping flat metal sheets into desired forms using a die and press. From automotive components to intricate microelectronics, metal stamping plays a critical role in delivering precision parts at scale.

One of the most advanced forms of this process is precision metal stamping, which enables the production of highly complex parts with tight tolerances. Unlike regular metal stamping, precision metal stamping combines state-of-the-art technology and meticulous engineering to meet the demanding requirements of industries such as medical devices and aerospace.

Definition of Precision Metal Stamping

Precision metal stamping is a highly accurate manufacturing process used to form metal components with tight tolerances and intricate geometries. By utilizing specialized dies and advanced presses, this process transforms flat metal sheets into desired shapes through a series of operations. Precision metal stamping stands apart from conventional methods by emphasizing extremely close dimensional tolerances, often within micrometers, and the ability to produce complex features and fine details.

This makes it a critical technique for industries requiring high-quality, consistent, and reliable components, such as aerospace, medical devices, and automotive manufacturing.

Key Characteristics of Precision Metal Stamping:

- Tight Tolerances: Ensures part interchangeability and functionality in demanding applications.

- Intricate Geometries: Capable of producing complex shapes, fine details, and miniature components.

- High Repeatability: Consistent part quality and dimensional accuracy across production runs.

- Minimal Material Waste: Optimized die design and precise process control reduce scrap and maximize material usage.

The Process of Precision Metal Stamping

The precision metal stamping process is a series of carefully engineered stages, each contributing to the final quality and accuracy of the stamped components.

Die Design and Manufacturing

The foundation of precision metal stamping lies in the design and fabrication of high-precision dies. These tools are created with advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, ensuring they meet exacting standards.

Key elements of die design and manufacturing include:

- CAD Modeling: Creating detailed 3D models of the part and tooling, considering material properties, forming forces, and tolerances.

- CAM Programming: Generating CNC machining programs to precisely manufacture die components.

- Wire EDM (Electrical Discharge Machining): Cutting intricate shapes and details with extreme accuracy using electrical discharges.

- Grinding and Lapping: Achieving smooth surface finishes and tight tolerances on critical die surfaces.

- High-Quality Materials: Using durable tool steels, carbides, or specialty alloys to ensure the dies withstand repeated use and high pressure.

The quality and precision of the die directly determine the accuracy and repeatability of the stamped parts.

Material Selection

Selecting the right material is essential to achieving the desired performance and manufacturability of the part. Common materials used include:

- Steel: High strength and durability, available in various grades such as carbon steel and high-strength low-alloy (HSLA) steel.

- Aluminum: Lightweight and corrosion-resistant, ideal for applications where weight is a critical factor.

- Copper and Brass: Excellent electrical and thermal conductivity, suitable for electronics and electrical components.

- Stainless Steel: Provides corrosion resistance, strength, and aesthetic appeal, used in medical devices and consumer goods.

- Specialty Alloys: Materials like titanium, nickel alloys, and beryllium copper are chosen for their unique properties, such as biocompatibility or high temperature resistance.

Blanking

Blanking is the initial step, where flat metal sheets are cut into predefined shapes or "blanks." This process uses precision cutting dies to ensure:

- Accurate dimensions.

- Consistent starting shapes for further processing.

- Reduced material waste.

Forming

Forming operations shape the blank into its final geometry using various techniques:

- Bending: Creates angles or curves along a straight line.

- Drawing: Stretches the metal to form deep or complex shapes, like cups or enclosures.

- Coining: Compresses the material to create detailed features and improve surface finish.

- Embossing: Adds raised or recessed patterns to the surface for decorative or functional purposes.

Piercing/Punching

Piercing or punching creates holes, slots, or other internal features in the metal. Precision in this stage ensures:

- Accurate placement and size of features.

- Clean and smooth edges for assembly or functionality.

- High-speed production for parts requiring multiple features.

Trimming

Trimming removes excess material from the formed part to achieve the final desired shape. Precision trimming ensures:

- Smooth and clean edges.

- Exact dimensional accuracy.

Other Operations

Additional secondary processes can enhance the functionality and appearance of the parts:

- Deburring: Removes sharp edges or burrs for safety and smooth assembly.

- Surface Finishing: Adds coatings, plating, or polishing for corrosion resistance, wear resistance, or aesthetic appeal.

- Heat Treating: Improves mechanical properties such as strength and hardness by altering the material's microstructure.

- Assembly: Combines multiple stamped parts into complex assemblies.

Key Factors and Techniques in Precision Metal Stamping

Precision metal stamping combines advanced technology, meticulous process control, and specialized techniques to produce high-quality components with tight tolerances and intricate geometries. This document explores the key factors influencing precision metal stamping and provides a detailed overview of common techniques.

Key Factors in Precision Metal Stamping

Achieving precision in metal stamping relies on controlling several critical factors, including tolerances, die precision, equipment, and material properties.

Tolerances and Accuracy

Tolerances define the permissible variation in a part's dimensions, while accuracy measures how closely the stamped part matches the design specifications. Maintaining tight tolerances—often within micrometers (µm)—is essential for ensuring proper fit, function, and interchangeability in high-demand industries like electronics, medical devices, and aerospace.

Key elements affecting tolerances and accuracy:

- Die Accuracy: The precision of the die directly influences part quality. Any flaws in the die are replicated in the stamped components.

- Material Properties: Variations in thickness, hardness, and grain structure can impact dimensional accuracy.

- Press Stability: A stable and rigid press ensures consistent stamping forces, reducing deviations.

- Process Control: Precise control of press parameters (e.g., speed, pressure, lubrication) is vital for consistent results.

Die Precision

The quality of the die directly impacts the precision and durability of the stamping process. High-quality dies are meticulously crafted using advanced technologies like wire EDM, CNC machining, and surface grinding to achieve the required specifications.

Key aspects of die precision:

- Die Material: High-quality tool steels, carbides, and specialized alloys ensure durability and wear resistance.

- Die Design: Optimized designs account for part geometry and material properties, reducing stress concentrations and defects.

- Die Manufacturing: Techniques such as wire EDM, CNC machining, and grinding produce dies with tight tolerances and smooth finishes.

- Die Maintenance: Regular inspections, cleaning, and sharpening maintain die accuracy and longevity.

Equipment and Technology

Advanced stamping equipment ensures high precision, efficiency, and versatility.

Types of presses and technologies:

- Mechanical Presses: High-speed presses ideal for mass production.

- Hydraulic Presses: Provide greater control over pressure and stroke length, suitable for deep drawing and complex forming.

- Progressive Dies: Perform multiple operations in a single press stroke, enhancing production speed and consistency.

- Transfer Presses: Move individual blanks between stations, allowing for larger or more intricate parts.

- Servo Presses: Use servo motors to control ram motion, offering exceptional flexibility and precision.

Material Properties

Material selection is critical for achieving desired results. The mechanical properties of the material influence formability, durability, and quality.

Important material properties:

- Strength: Resistance to deformation and fracture.

- Ductility: Ability to stretch or draw without breaking.

- Hardness: Resistance to wear and indentation.

- Thickness: Uniform material thickness ensures consistent results.

- Grain Structure: Affects formability and surface finish.

Types of Precision Metal Stamping Techniques

Various techniques are employed in precision metal stamping to achieve specific shapes and features. Each method is chosen based on the application requirements.

Progressive Die Stamping

Progressive die stamping uses a series of dies in a single press. As the metal strip advances through the press, each die performs a specific operation, progressively shaping the part until it is fully formed and separated from the strip.

Key points:

- Applications: Ideal for high-volume production of parts with multiple features, such as connectors, brackets, and clips.

- Advantages:

- High efficiency and production speed.

- Consistent quality across large runs.

- Cost-effective for complex parts.

Deep Draw Stamping

Deep draw stamping involves forming a flat metal blank into a deep, cup-shaped, or hollow part by forcing it into a die cavity using a punch.

Key points:

- Applications: Commonly used for manufacturing cans, containers, and automotive components.

- Advantages:

- Produces seamless parts with excellent structural integrity.

- Reduces the need for welding or additional assembly.

- Suitable for complex shapes with smooth finishes.

Transfer Die Stamping

Transfer die stamping involves transferring individual blanks between multiple die stations, with each station performing a specific operation.

Key points:

- Applications: Suitable for large or complex parts, such as automotive body panels and structural components.

- Advantages:

- Flexibility for more intricate operations.

- Ability to handle larger part sizes compared to progressive stamping.

- Precise control over each forming stage.

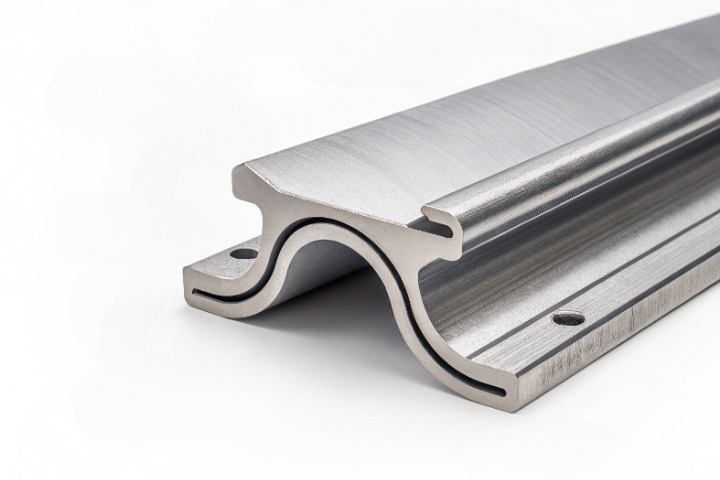

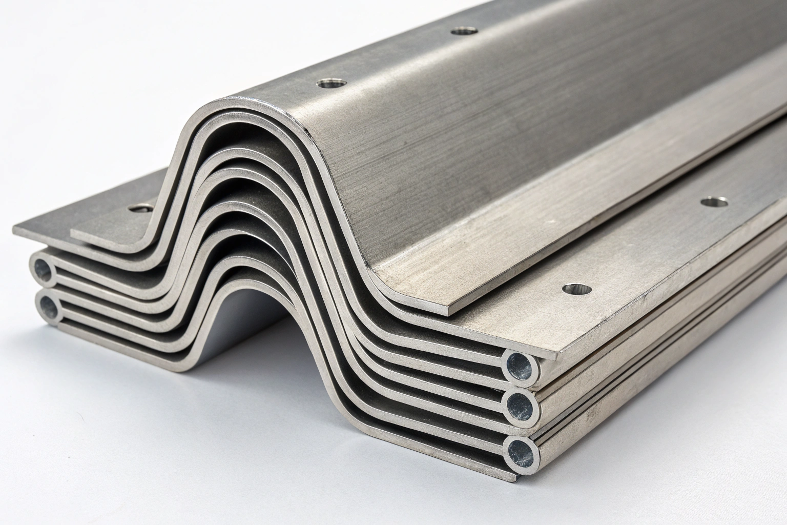

Fineblanking

Fineblanking is a specialized stamping process that produces parts with extremely smooth edges and tight tolerances. It uses a die with a V-ring or other cutting element to achieve clean cuts without tearing.

Key points:

- Applications: Commonly used for precision parts requiring intricate features, such as gears and cams.

- Advantages:

- High-quality edge finishes.

- Ability to produce complex features with precision.

- Minimal need for secondary finishing.

Materials and Advantages of Precision Metal Stamping

Precision metal stamping combines versatile material options with highly efficient production techniques, making it indispensable across a wide range of industries. Below is a detailed analysis of the materials used, key advantages, and applications.

Materials Used in Precision Metal Stamping

The choice of material is critical in precision metal stamping, as it directly affects performance, durability, and cost. A wide range of metals and alloys are used to meet specific application requirements.

Common Metals

-

Steel:

- Carbon Steel: Combines strength and affordability, suitable for general-purpose applications.

- Alloy Steel: Enhanced with elements like chromium and molybdenum for improved wear resistance and toughness.

- High-Strength Low-Alloy (HSLA) Steel: Offers excellent strength-to-weight ratios, ideal for weight-sensitive applications like automotive and aerospace.

- Tool Steel: Used in die fabrication due to its hardness and resistance to deformation under high stress.

-

Aluminum:

- Lightweight and Corrosion-Resistant: Perfect for aerospace and automotive components.

- 1xxx Series: Pure aluminum, known for high conductivity and corrosion resistance.

- 5xxx Series: Magnesium alloys for high strength and good weldability.

- 6xxx Series: Magnesium-silicon alloys offering formability and heat treatability.

-

Copper:

- Pure Copper: Renowned for its electrical and thermal conductivity, ideal for electrical components.

- Brass: A copper-zinc alloy valued for machinability and corrosion resistance.

- Bronze: A copper-tin alloy with high strength and wear resistance.

Alloys

Specialized alloys deliver unique performance attributes for demanding applications:

-

Stainless Steel: Combines corrosion resistance, strength, and aesthetic appeal. Grades include:

- Austenitic Stainless Steel: Excellent for corrosion resistance and ductility.

- Martensitic Stainless Steel: Provides high strength and hardness.

-

Titanium: Lightweight with exceptional corrosion resistance and biocompatibility, used in aerospace and medical devices.

-

Nickel Alloys: Offer superior heat resistance and strength for high-temperature environments.

-

Beryllium Copper: High conductivity and wear resistance, ideal for electrical connectors and springs.

Advantages of Precision Metal Stamping

Precision metal stamping offers several advantages, making it a preferred manufacturing process for large-scale production.

High Volume Production

- Efficiency: Stamping presses can produce thousands of identical parts per hour.

- Scalability: Once the die is created, scaling up production is straightforward and cost-effective.

Cost-Effectiveness

- Economy of Scale: High initial tooling costs are offset by reduced per-unit costs in large production runs.

- Reduced Labor: Automation minimizes manual intervention, reducing operational costs.

- Material Utilization: Optimized die designs minimize waste, further reducing expenses.

Consistency and Repeatability

- Precision Engineering: Advanced dies and stamping equipment ensure dimensional consistency across all parts.

- Quality Assurance: Automated processes and tight tolerances reduce defects, ensuring uniformity.

Tight Tolerances and Precision

- Dimensional Accuracy: Tolerances within micrometers make it suitable for complex geometries and miniature components.

- Enhanced Functionality: High precision enables parts to integrate seamlessly with other components.

Material Efficiency

- Optimized Design: Efficient use of materials reduces scrap rates and supports sustainability efforts.

- Cost Savings: Minimizing waste lowers material costs and improves environmental impact.

Applications of Precision Metal Stamping

Precision metal stamping is vital across various industries due to its versatility and efficiency.

Automotive

- Body Panels: Stamping produces hoods, doors, and fenders with uniform quality.

- Structural Components: Chassis parts, brackets, and reinforcements are precisely stamped for durability.

- Engine and Transmission Parts: High-precision gears and valves are manufactured using techniques like fineblanking.

- Trim Components: Decorative bezels and interior elements benefit from tight tolerances and consistent aesthetics.

Electronics

- Connectors and Terminals: Small, intricate components for efficient electrical connections.

- Shielding and Housings: Stamped metal enclosures provide EMI shielding and protect sensitive electronics.

- Lead Frames: Used in semiconductors to ensure reliable electrical connections.

Medical Devices

- Surgical Instruments: High precision and biocompatibility are critical for components used in surgery.

- Implants: Durable, lightweight components tailored for human implantation.

- Equipment Housings: Enclosures for diagnostic tools and medical devices.

Aerospace

- Structural Components: Lightweight and high-strength parts for aircraft structures.

- Engine Components: Complex, heat-resistant parts used in propulsion systems.

- Cabin Components: Interior panels and brackets designed for lightweight efficiency.

Consumer Goods

- Appliances: Stamped components for durability and precision in household items.

- Hardware: Hinges, brackets, and fasteners with uniform quality.

- Tools: Components for hand and power tools, ensuring strength and precision.

Challenges in Precision Metal Stamping

While precision metal stamping provides exceptional results, it requires addressing several inherent challenges to ensure successful implementation.

Tooling Costs

The design and fabrication of high-quality dies involve substantial upfront investment, influenced by the following factors:

- Die Complexity: Complex part geometries necessitate intricate die designs, increasing costs.

- Die Size: Larger dies require more material and machining time, driving up expenses.

- Die Material: High-quality tool steels or carbides add durability but also increase initial costs.

- Production Volume: While high-volume production amortizes tooling costs, the initial investment remains a significant barrier for small-scale runs.

Tooling costs can be mitigated through optimized design processes and durable materials to extend die life and reduce maintenance needs.

Material Limitations

The material properties can impose restrictions on the precision stamping process:

- Material Thickness: Extremely thick materials require high stamping forces, leading to increased die wear and potential deformation.

- Material Hardness: Harder materials, such as titanium, may be prone to cracking and necessitate specialized techniques.

- Material Ductility: Low-ductility materials may tear or crack during forming.

- Complex Geometries: Parts with intricate shapes often demand multiple stamping stages or advanced methods, increasing costs and complexity.

Addressing these limitations requires selecting materials suited for stamping processes and leveraging advanced press technologies.

Maintaining Precision

Precision is the hallmark of precision metal stamping, but maintaining accuracy throughout production involves overcoming several hurdles:

- Die Wear: Repeated use can degrade dies, reducing part accuracy and increasing defects. Regular maintenance, such as sharpening and polishing, is critical.

- Process Control: Consistent parameters, including press speed, pressure, and lubrication, are essential for maintaining uniformity.

- Material Variability: Differences in thickness, hardness, or surface finish can affect part dimensions and quality.

- Environmental Factors: Temperature and humidity variations can influence material behavior and dimensional accuracy, necessitating controlled production environments.

Proactive maintenance schedules, real-time monitoring systems, and strict quality controls are essential to preserving precision.

Future Trends in Precision Metal Stamping

Emerging trends and technological advancements are reshaping the field of precision metal stamping, offering solutions to current challenges and expanding its capabilities.

Advanced Materials

The development of new materials is enhancing product performance and enabling applications in high-demand industries:

- High-Strength Lightweight Materials: Advanced high-strength steels (AHSS), aluminum alloys, and composites are increasingly used in automotive and aerospace industries to reduce weight while maintaining strength.

- Advanced Alloys: Corrosion-resistant and high-temperature alloys, such as nickel-based superalloys and titanium, are tailored for extreme environments.

- Biocompatible Materials: Materials like nitinol and cobalt-chromium alloys are gaining popularity in medical applications due to their biocompatibility.

Automation and Robotics

Automation is revolutionizing precision metal stamping, improving efficiency and consistency:

- Robotic Systems: Automated material handling systems for loading, unloading, and part transfer reduce cycle times and labor costs.

- Sensors and Monitoring: Smart presses equipped with sensors enable real-time process monitoring and automatic adjustments to stamping parameters.

- Collaborative Robots (Cobots): Cobots work alongside human operators to increase productivity and safety.

Simulation and Modeling

Computer-aided engineering (CAE) tools are becoming essential in optimizing the stamping process:

- Die Design Optimization: Advanced simulation tools predict material flow, stress points, and potential defects, reducing trial-and-error during die manufacturing.

- Process Simulation: Virtual models help identify and resolve issues like wrinkling or cracking before production begins, saving time and resources.

- Digital Twins: Virtual replicas of the stamping process allow for continuous optimization and monitoring.

Micro-Stamping and Nano-Stamping

The demand for miniature components in industries such as electronics and medical devices is driving advancements in micro-stamping and nano-stamping:

- Micro-Stamping: Produces parts with dimensions in the micrometer range for applications like microelectronics and precision instruments.

- Nano-Stamping: Enables the creation of nanoscale features, opening up possibilities in photonics, nanotechnology, and advanced electronics.

These specialized techniques require ultra-precise tooling and cutting-edge machinery to achieve high accuracy at small scales.

Glossary of Terms

- Blanking: A cutting operation that removes a piece of material (the blank) from a larger sheet or strip. The blank becomes the part.

- Piercing: A cutting operation that creates holes or features in the material, with the removed material considered scrap.

- Progressive Die: A die that performs multiple operations sequentially as the material moves through the press.

- Drawing: A forming operation that stretches the metal into a hollow or cup-shaped part.

- Coining: Compresses metal to create precise features and improve surface finish.

- Trimming: Removes excess material to achieve the desired shape and dimensions.

- Deburring: Eliminates sharp edges or burrs from stamped parts for safety and quality.

- Tolerance: The allowable variation in a part's dimensions, critical for achieving precision.

- Die: A specialized tool used to shape metal in stamping operations.

- Punch: The part of the die assembly that applies force to the material.

Conclusion

Precision metal stamping is a cornerstone of modern manufacturing, enabling the production of complex, high-quality parts at scale. Its versatility, cost-effectiveness, and ability to meet tight tolerances make it essential across industries. To learn more about how precision metal stamping can benefit your business, feel free to reach out to our experts today!

FAQ:

What is precision stamping?

Precision stamping is a high-accuracy manufacturing process used to shape metal components with tight tolerances and intricate geometries. It utilizes specialized dies and advanced machinery to produce consistent and complex parts, making it ideal for industries like automotive, aerospace, electronics, and medical devices.

What are the four types of metal stamping?

The four main types of metal stamping are:

- Progressive Die Stamping: Uses a series of dies to perform multiple operations in a single press stroke, ideal for high-volume production.

- Deep Draw Stamping: Stretches the metal into deep or hollow shapes, often used for components like cans or medical housings.

- Transfer Die Stamping: Transfers individual parts between stations, allowing for complex operations and larger parts.

- Fineblanking: Produces parts with exceptionally smooth edges and tight tolerances, commonly used for gears and other precision components.

What is precision metal?

Precision metal refers to metal components manufactured with extremely tight tolerances and high dimensional accuracy. These components are often used in applications where precision is critical, such as medical implants, aerospace parts, and high-performance electronics.

How accurate is metal stamping?

Metal stamping can achieve tolerances as tight as ±0.002 inches (50 micrometers) or even finer, depending on the material and process. Precision stamping ensures consistent dimensional accuracy, making it suitable for intricate designs and high-quality production requirements.