Stainless steel is celebrated for its durability and resistance to corrosion, but even this robust material isn't immune to challenges like extreme humidity, harsh chemicals, or abrasive conditions. In such environments, stainless steel may suffer from discoloration, surface damage, or reduced longevity. This can lead to higher maintenance costs, compromised performance, or premature replacement—issues that can be avoided with the right protective measures. Applying a specialized coating enhances its performance, extends its lifespan, and preserves its aesthetic appeal. But how do you know when coating is truly necessary?

Direct Answer:

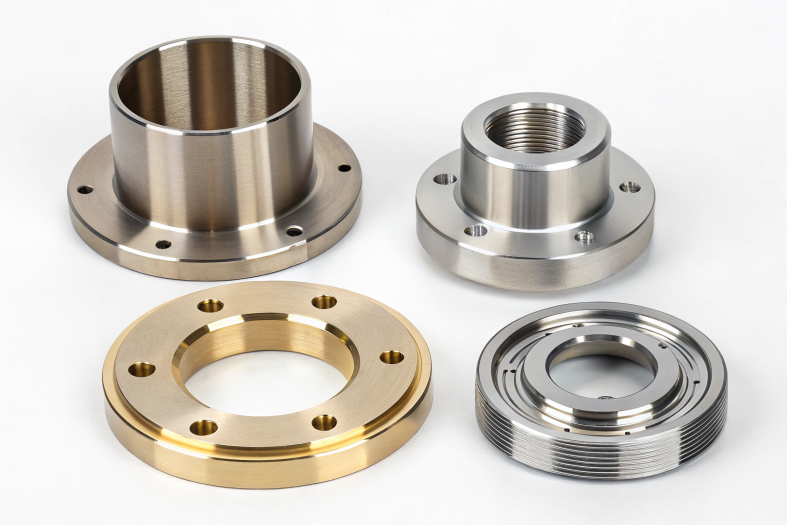

Stainless steel products need coating when exposed to extreme environments, such as marine or chemical settings, where the passive layer may fail, or when enhanced properties like increased hardness, wear resistance, or biocompatibility are required. Coating is also necessary for achieving specific aesthetics, reducing friction, providing electrical insulation, or extending the lifespan of components. Common coatings include PVD, electroplating, ceramic, and powder coatings, each tailored to meet functional and environmental demands.

What is Stainless Steel and Why is it Corrosion Resistant?

Stainless steel is a family of iron-based alloys, renowned for their exceptional corrosion resistance. This inherent property makes stainless steel indispensable across a wide range of industries, from kitchenware and architectural applications to industrial equipment and medical implants. The key to this corrosion resistance lies in its unique composition and the formation of a protective passive layer.

Composition

Stainless steel is defined by its minimum chromium content of 10.5% by mass, which is the primary element responsible for its corrosion-resistant properties. The alloy is primarily composed of:

- Iron (Fe): The base element, providing the structural backbone of the material.

- Chromium (Cr): The crucial alloying element that forms the passive layer, essential for corrosion resistance.

- Nickel (Ni): Improves ductility, toughness, and resistance to high temperatures.

- Molybdenum (Mo): Enhances resistance to pitting and crevice corrosion, particularly in chloride-rich environments.

- Additional Elements: Elements such as manganese (Mn), silicon (Si), and carbon (C) are added in varying amounts to tailor specific properties like strength, weldability, and oxidation resistance.

The precise composition of these elements determines the specific grade and properties of stainless steel, allowing it to be optimized for different applications.

Passive Layer Formation

The remarkable corrosion resistance of stainless steel is primarily due to the formation of a thin, invisible, and self-repairing passive layer on its surface.

How the Passive Layer Forms

- Reaction with Oxygen: When chromium in stainless steel comes into contact with oxygen (even trace amounts in air or water), it reacts to form chromium oxide (Cr₂O₃).

- Protective Barrier: This chromium oxide layer is extremely thin—just a few nanometers thick—and adheres tightly to the metal surface. It acts as a barrier, preventing oxygen and moisture from reaching the underlying iron and forming rust (iron oxide).

- Self-Healing Property: If scratched or damaged, the passive layer regenerates in the presence of oxygen, restoring its protective function. This self-repairing characteristic is a defining feature of stainless steel.

Limits of the Passive Layer

While stable in neutral and alkaline environments and many oxidizing acids, the passive layer can be compromised in aggressive conditions, such as:

- Chlorides (e.g., seawater, salt spray): Can cause localized pitting and crevice corrosion.

- Reducing Acids (e.g., hydrochloric acid): May attack the passive layer.

Grades of Stainless Steel

Stainless steel comes in various grades, each tailored to specific environments and applications. The grades differ based on their alloying elements and intended use.

304 Stainless Steel (18/8)

- Composition: Contains approximately 18% chromium and 8% nickel, often referred to as "18/8 stainless steel."

- Applications: Widely used for general purposes, including food processing equipment, kitchen appliances, and structural components.

- Corrosion Resistance: Offers excellent resistance in most environments but is vulnerable to pitting corrosion in chloride-rich settings.

316 Stainless Steel (18/10/2)

- Composition: Similar to 304, with the addition of 2-3% molybdenum.

- Applications: Commonly used in marine environments, chemical processing plants, and medical devices.

- Enhanced Resistance: Molybdenum significantly improves resistance to pitting and crevice corrosion, especially in saline and chloride-heavy environments.

Other Considerations

- 430 Stainless Steel: A ferritic grade with moderate corrosion resistance, often used in decorative applications.

- 2205 Duplex Stainless Steel: Combines high strength with superior resistance to stress corrosion cracking, suitable for demanding industrial applications.

Factors Influencing Corrosion Resistance

- Chromium Content: Higher chromium levels enhance the robustness of the passive layer.

- Environmental Conditions: Factors such as salinity, temperature, and pH levels affect performance.

- Surface Finish: Smoother finishes reduce sites for contaminant accumulation, enhancing corrosion resistance.

- Maintenance: Regular cleaning helps preserve the passive layer and prevent localized corrosion.

Why Consider Coating Stainless Steel?

Stainless steel is highly regarded for its inherent corrosion resistance, which is attributed to its passive chromium oxide layer. However, there are scenarios where its natural properties are insufficient, and additional coatings become necessary to enhance its performance, aesthetics, or longevity. Below are the key reasons to consider coating stainless steel:

- Environmental Challenges: Aggressive environments, such as marine or chemical settings, can compromise the passive layer, leading to corrosion.

- Aesthetic Goals: Coatings enable a variety of colors, textures, and finishes that raw stainless steel cannot achieve.

- Functional Enhancements: Coatings improve properties like hardness, wear resistance, reduced friction, and electrical insulation.

- Long-Term Cost Savings: By protecting the material from damage and extending its lifespan, coatings reduce maintenance and replacement costs.

Situations Where Coating is Necessary or Beneficial

1. Extreme Environments

Certain environments challenge even the most corrosion-resistant grades of stainless steel. Coatings provide an essential layer of defense in these situations:

-

Marine Applications:

Seawater and marine atmospheres are rich in chlorides, which can penetrate the passive layer of stainless steel and initiate pitting corrosion. Even 316 stainless steel, known for its chloride resistance, benefits from coatings that add a robust barrier against saltwater damage. -

Chemical Processing:

Stainless steel exposed to strong acids (e.g., sulfuric or hydrochloric acid) or bases (e.g., sodium hydroxide) may experience degradation of its passive layer. Coatings specifically formulated to resist chemical attack protect the substrate and maintain its structural integrity. -

High Temperatures:

Prolonged exposure to high temperatures can lead to oxidation or scaling, compromising the passive layer. Heat-resistant coatings protect stainless steel in applications like industrial furnaces or exhaust systems.

2. Aesthetic Reasons

Coatings expand the visual and design possibilities for stainless steel:

-

Color and Texture:

Vibrant colors, unique textures (matte, gloss, patterned), and finishes that are unattainable with raw stainless steel can be achieved through coatings. This is particularly valuable in architectural, decorative, and consumer product applications. -

Matching Components:

Coatings help align the appearance of stainless steel with other materials in assemblies, ensuring a cohesive and aesthetically pleasing design.

3. Increased Hardness and Wear Resistance

Stainless steel's natural hardness can be insufficient for high-friction or abrasive applications. Coatings significantly enhance durability:

-

Cutting Tools and Dies:

Coatings like titanium nitride (TiN) or diamond-like carbon (DLC) increase hardness, improve cutting performance, and extend tool lifespan. -

Bearings and Valves:

Components exposed to continuous contact and movement benefit from wear-resistant coatings, reducing the risk of premature failure.

4. Reduced Friction

Low-friction coatings are crucial for applications requiring smooth movement or reduced wear:

-

Medical Devices:

Coatings on surgical instruments and implants reduce friction during use, minimizing tissue damage and enhancing patient comfort. -

Food Processing Equipment:

Low-friction surfaces prevent food from sticking, improving hygiene and cleaning efficiency. -

Sliding Components:

Machinery and equipment with moving parts experience reduced wear and increased efficiency when coated.

5. Improved Biocompatibility

For medical applications, biocompatible coatings enhance the safety and functionality of stainless steel implants:

- Medical Implants:

Coatings prevent adverse reactions with body tissues, reducing inflammation or rejection. Some coatings also promote osseointegration (bone growth onto the implant), crucial for orthopedic devices.

6. Electrical Insulation

Stainless steel’s conductivity makes it unsuitable for certain applications without added insulation:

- Electrical Components:

Non-conductive coatings provide electrical insulation, ensuring safety in electrical enclosures and preventing short circuits.

Summary of Benefits

Coating stainless steel extends its functionality, aesthetics, and longevity by:

- Protecting Against Environmental Damage: Adds an extra barrier in harsh conditions.

- Enhancing Appearance: Provides unique finishes and consistent aesthetics.

- Improving Durability: Increases hardness and wear resistance for demanding applications.

- Reducing Friction: Facilitates smoother operation in moving parts.

- Ensuring Biocompatibility: Supports medical and health-related use cases.

- Providing Electrical Insulation: Enables use in electronic and industrial applications.

Stainless steel coatings address specific challenges and expand the material's utility, making it a versatile choice for a wide range of industries.

Types of Coatings for Stainless Steel

Stainless steel coatings enhance the material's durability, aesthetics, and performance in various environments. Each coating type serves specific purposes, with unique processes, advantages, and applications. Below is a comprehensive guide to the most common coating technologies for stainless steel:

1. PVD (Physical Vapor Deposition) Coatings

Process:

PVD is a vacuum-based process where a solid material is vaporized and deposited as a thin, tightly adhered film onto the stainless steel surface. Techniques include:

- Evaporation: Coating material is vaporized using heat, electron beams, or arc evaporation.

- Sputtering: High-energy ions bombard a target material, ejecting atoms to deposit on the substrate.

Advantages:

- High Hardness and Wear Resistance: Significantly increases surface durability, protecting against abrasion and erosion.

- Corrosion Protection: Forms a dense, impervious barrier that enhances resistance to corrosive environments.

- Thin and Uniform Coating: Conforms precisely to the surface, maintaining fine details of the substrate.

- Strong Adhesion: Ensures long-term performance and durability.

Examples:

- Titanium Nitride (TiN): Known for its gold-like appearance, extreme hardness, and wear resistance. Widely used in cutting tools, dies, and decorative applications.

- Chromium Nitride (CrN): Offers excellent corrosion resistance and moderate wear protection, suitable for automotive and molding applications.

- Diamond-Like Carbon (DLC): Combines exceptional hardness with low friction, ideal for medical devices, engine components, and precision tools.

Applications:

Used in aerospace, automotive, medical devices, and decorative industries where enhanced durability and aesthetics are critical.

2. Electroplating

Process:

Electroplating uses an electric current to deposit a thin layer of metal onto the stainless steel surface. The part is immersed in an electrolyte solution containing the desired metal ions, and an electric current facilitates the deposition.

Advantages:

- Decorative Finishes: Achieves bright, lustrous finishes in various metals.

- Corrosion Protection: Provides additional resistance to environmental factors in mild conditions.

Examples:

- Nickel Plating: Creates a smooth, corrosion-resistant surface, often used as a base for other coatings.

- Chromium Plating: Offers a hard, reflective, and wear-resistant surface, commonly found in automotive trim and plumbing fixtures.

- Gold Plating: Ensures excellent conductivity and corrosion resistance for electronics and decorative applications.

Applications:

Ideal for automotive parts, jewelry, plumbing fixtures, and consumer products requiring aesthetic appeal and mild corrosion protection.

3. Painting and Powder Coating

Process:

- Painting: Liquid paint is applied to the stainless steel surface via brushes, rollers, or spraying.

- Powder Coating: A dry powder is electrostatically applied and cured under heat to form a smooth, durable finish.

Advantages:

- Aesthetic Variety: Offers a wide range of colors, textures, and finishes.

- Basic Corrosion Protection: Acts as a barrier against moisture and mild corrosive agents.

Applications:

Commonly used in architectural components, appliances, furniture, and outdoor equipment where aesthetics are a primary concern.

Considerations:

Proper surface preparation is essential for adhesion. These coatings are less durable in harsh environments compared to PVD or ceramic coatings.

4. Ceramic Coatings

Process:

Ceramic coatings consist of inorganic, non-metallic materials like oxides, carbides, or nitrides. These coatings are applied through plasma spraying or chemical vapor deposition (CVD).

Advantages:

- High-Temperature Resistance: Withstands extreme heat without degradation.

- Wear and Abrasion Resistance: Exceptional durability under high-friction conditions.

- Corrosion Resistance: Effective against chemical attacks and marine environments.

Applications:

Common in high-temperature and high-stress environments, such as:

- Exhaust systems for automotive and industrial use.

- Aerospace components like turbine blades.

- Industrial furnaces and chemical processing equipment.

5. Organic Coatings (e.g., Epoxy, Polyurethane)

Process:

Organic coatings are based on polymers and applied as liquids or powders. They cure to form a protective, flexible barrier on stainless steel.

Advantages:

- Corrosion Protection: Shields against moisture, chemicals, and atmospheric exposure.

- Chemical Resistance: Specialized formulations resist specific corrosive agents.

- Cost-Effective: Affordable for large-scale applications.

Examples:

- Epoxy Coatings: Offer excellent adhesion, chemical resistance, and durability, commonly used for pipelines and storage tanks.

- Polyurethane Coatings: Provide abrasion resistance, UV stability, and flexibility, ideal for outdoor and structural applications.

Applications:

Used in industrial equipment, marine structures, storage tanks, and pipelines for long-term corrosion protection.

How to Select the Right Coating?

Selecting the appropriate coating for stainless steel is a critical process that involves evaluating the environment, performance requirements, cost considerations, and application feasibility. Making an informed choice ensures optimal performance, durability, and long-term cost efficiency.

Factors to Consider

-

Service Environment

A thorough assessment of the operating environment is essential to determine the coating requirements:- Temperature:

- For high-temperature environments, such as furnaces or exhaust systems, ceramic or PVD coatings are ideal.

- Organic coatings may degrade at elevated temperatures.

- Humidity:

- High humidity accelerates corrosion, especially in contaminated environments. Coatings like epoxy or powder coatings provide an effective barrier.

- Chemical Exposure:

- Identify chemicals, their concentration, and exposure duration. Coatings resistant to acids, bases, and solvents (e.g., ceramic or organic coatings) are necessary for chemical-rich environments.

- Abrasion and Erosion:

- Applications involving contact with abrasive materials or high-velocity particles demand wear-resistant coatings like PVD or ceramic.

- Temperature:

-

Required Performance Properties

- Corrosion Resistance:

- Choose coatings that offer the required level of protection for the application’s environmental conditions.

- Hardness and Wear Resistance:

- For applications like cutting tools or bearings, select coatings with high surface hardness, such as PVD or DLC.

- Friction Reduction:

- Low-friction coatings are essential for sliding or moving parts, e.g., in medical devices or food processing equipment.

- Aesthetics:

- Decorative applications may prioritize coatings that offer vibrant colors, textures, or finishes.

- Biocompatibility:

- For medical implants, coatings must ensure safety and compatibility with body tissues.

- Electrical Conductivity/Insulation:

- Determine whether the coating should be conductive (e.g., gold plating) or insulating (e.g., organic coatings).

- Corrosion Resistance:

-

Cost

- Initial Cost:

- Assess the expense of the coating material and application method.

- Long-Term Cost:

- Factor in maintenance, repairs, and replacement costs. Higher-quality coatings often justify their cost by reducing long-term expenses.

- Initial Cost:

-

Application Method

- Coating Thickness:

- Different methods offer varying levels of thickness, which may affect durability and appearance.

- Substrate Geometry:

- Complex shapes may require specialized techniques for uniform coverage.

- Adhesion:

- Ensure the method provides strong adhesion to stainless steel, especially in high-stress environments.

- Coating Thickness:

Case Studies: Real-World Applications

1. Marine Industry

- Challenges:

Constant exposure to saltwater accelerates corrosion, even in high-grade stainless steel like 316. - Solutions:

- Epoxy Coatings: Provide robust corrosion resistance for general marine applications.

- PVD Coatings: Used on critical components like propeller shafts to prevent pitting and extend service life.

2. Automotive Industry

- Challenges:

Components face high temperatures, friction, and chemical exposure. - Solutions:

- Ceramic Coatings: Protect exhaust systems from oxidation and heat damage.

- Powder Coatings: Enhance the durability and aesthetic appeal of wheels and trims.

- DLC Coatings: Reduce friction and wear in engine components.

3. Medical Industry

- Challenges:

Implants and surgical tools require biocompatibility and resistance to bodily fluids. - Solutions:

- Titanium Nitride (TiN): Promotes osseointegration and prevents tissue reactions.

- Hydroxyapatite Coatings: Enhance implant integration with bone.

4. Food Processing Industry

- Challenges:

Equipment must comply with food-grade standards and resist cleaning chemicals. - Solutions:

- Epoxy Coatings: Ensure chemical resistance and hygiene.

- Low-Friction Coatings: Prevent food from sticking to processing surfaces, improving efficiency.

Maintenance and Care for Coated Stainless Steel

Proper maintenance extends the lifespan and ensures the performance of coated stainless steel components:

1. Cleaning

- Use mild, non-abrasive cleaners and soft sponges or cloths to avoid scratching or damaging the coating.

- Avoid harsh chemicals, scouring pads, and steel wool, which can degrade the coating.

- Rinse thoroughly with clean water and dry surfaces to prevent water spots and stains.

2. Inspection

- Regularly check for signs of damage, including chips, scratches, cracks, or discoloration.

- Focus on areas exposed to high stress, abrasion, or corrosive environments.

3. Repairs

- Address damage promptly:

- Minor scratches may be repaired with touch-up products suitable for the coating type.

- Significant damage may require professional recoating to restore protection.

- Consult with coating specialists for appropriate repair methods and materials.

Conclusion

Selecting the right coating for stainless steel is essential for optimizing its performance and durability in various applications. Whether in extreme environments, for aesthetic purposes, or to enhance specific properties like wear resistance or biocompatibility, tailored coatings can significantly improve the functionality and lifespan of stainless steel.

By carefully evaluating environmental conditions, performance requirements, cost considerations, and application methods, you can ensure that the chosen coating meets the demands of the specific use case. Real-world examples across industries, such as marine, automotive, medical, and food processing, demonstrate how coatings provide superior protection, improved aesthetics, and reduced maintenance costs.

Additionally, proper maintenance practices, including regular cleaning, inspection, and timely repairs, ensure the long-term effectiveness of coated stainless steel. With the right coating and care, stainless steel components can deliver exceptional performance and value, even in the most demanding environments.

Unsure about the best coating for your stainless steel product? Don’t leave your investment to chance. Consult with our experts today at PROMACHINED for tailored recommendations that align with your application’s unique requirements. Whether you need enhanced corrosion resistance, improved aesthetics, or specialized functional properties, we’ll help you choose the right solution to maximize performance and longevity. Contact us now to get started!

FAQs

1. Does all stainless steel need coating?

No, coating is necessary only in specific environments or applications.

2. What are the most durable coatings for stainless steel?

Ceramic coatings and PVD coatings are among the most durable.

3. How much does coating stainless steel cost?

The cost depends on the type of coating and the application method.

4. Can stainless steel rust if coated improperly?

Yes, improper application or damage to the coating can lead to rusting.