Introduction

-

What is PTFE?

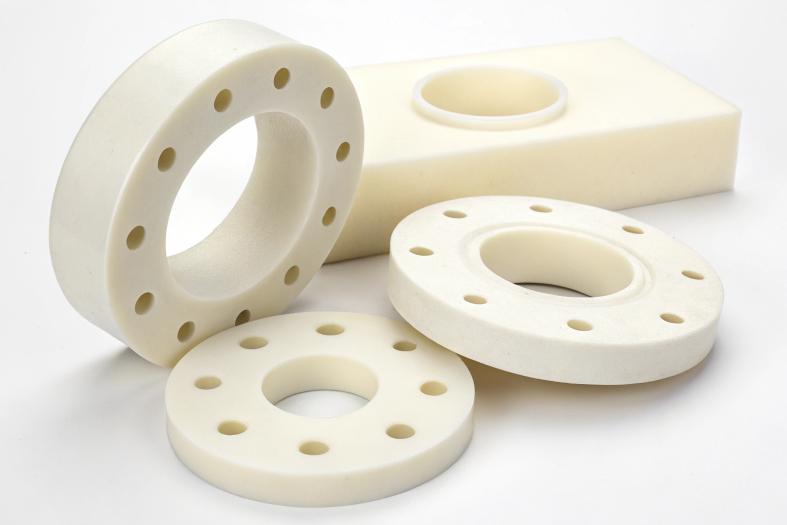

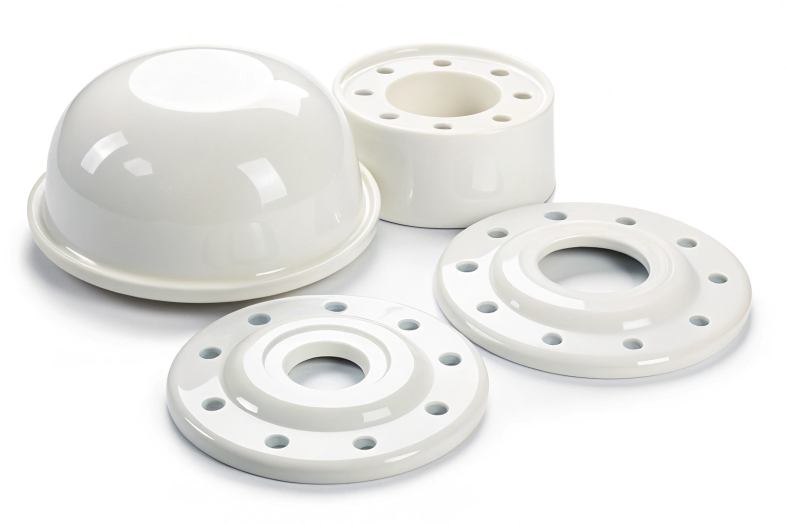

PTFE (Polytetrafluoroethylene), commonly known as Teflon, is a high-performance polymer with remarkable properties such as chemical inertness, high-temperature resistance, and an ultra-low coefficient of friction. These features make PTFE indispensable in industries like aerospace, medical devices, and chemical processing. -

Challenges in Machining PTFE

Machining PTFE presents unique challenges due to its softness, high thermal expansion, and creep (cold flow). Additionally, achieving a smooth surface finish and preventing deformation under load require careful handling and advanced techniques.

Direct Answer:

To efficiently machine PTFE, use sharp tools, low cutting speeds, light feeds, and proper cooling to prevent deformation and ensure smooth finishes.

Understanding PTFE's Properties and Their Impact on Machining

PTFE (Polytetrafluoroethylene), widely known as Teflon, is a high-performance polymer with exceptional properties that make it ideal for demanding applications. However, these same properties pose significant challenges during machining. Below is an in-depth exploration of PTFE’s key characteristics and their machining implications.

Softness and Flexibility

PTFE is an extremely soft and pliable material, with a low modulus of elasticity. While this makes it highly versatile for various applications, it also introduces the following challenges during machining:

-

Deformation During Cutting:

PTFE’s softness causes it to "push away" from cutting tools, particularly if dull or improperly angled tools are used. This results in dimensional inaccuracies and uneven surface finishes. -

Tool Selection and Maintenance:

Sharp, high-speed steel (HSS) or carbide tools with polished cutting edges are essential to minimize resistance and avoid material dragging or smearing. Tool sharpness must be maintained through regular replacement to achieve consistent results.

Practical Tip: Use light cutting forces and low feed rates to prevent overstressing the material. Support the workpiece adequately to minimize deformation.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion, which is significantly greater than that of metals. This property impacts machining in the following ways:

-

Dimensional Instability:

When exposed to heat during machining, PTFE expands significantly, which can temporarily alter dimensions and compromise tolerances. -

Post-Cooling Shrinkage:

After machining, PTFE contracts as it cools, potentially causing parts to deviate from specified dimensions.

Mitigation Strategies:

-

Temperature Control:

Use high-speed cutting with minimal heat generation. Employ cooling methods like compressed air or water-based coolants to maintain dimensional stability. -

Incremental Machining:

Machining PTFE in stages with cooling periods between passes helps reduce thermal distortion and ensures precise tolerances.

Industry Example: In aerospace seal production, where tolerances as tight as ±0.001" are required, pre-machining stress-relief processes are often employed to stabilize PTFE before final cutting.

Creep (Cold Flow)

Creep, or cold flow, refers to PTFE's tendency to deform under constant load, even at room temperature. This property complicates clamping and fixturing during machining.

-

Clamping Deformation:

Standard clamping methods can leave impressions or distort the material, particularly if excessive pressure is applied. -

Stability of Machined Features:

Thin walls or intricate details in PTFE components may warp over time if not properly supported.

Best Practices:

-

Custom Fixtures:

Use specialized fixturing solutions, such as soft jaws or vacuum clamps, to distribute pressure evenly across the workpiece. -

Reduced Clamping Pressure:

Apply just enough pressure to stabilize the part without inducing deformation.

Expert Insight: For medical-grade components, oversized blanks are often used, with material removed gradually to reduce stress and minimize the impact of creep.

Low Thermal Conductivity

PTFE has very low thermal conductivity, meaning it does not dissipate heat effectively during machining. This can lead to localized heat buildup, resulting in:

-

Surface Smearing:

Excessive heat softens PTFE, causing it to smear and produce rough or uneven finishes. -

Tool Wear:

Heat transfer to cutting tools accelerates wear, reducing tool life and cutting efficiency.

Cooling Techniques:

-

Coolant Usage:

Non-aromatic, water-based coolants or compressed air are effective for dissipating heat during machining. -

Sharp Tools with Polished Edges:

Minimize friction and improve chip evacuation by using well-maintained tools designed for plastics.

Real-World Application: In chemical-resistant gasket manufacturing, water-based cooling systems have been shown to improve surface finish by 25% and extend tool life by 30%.

Summary of PTFE Properties and Their Impact

| Property | Challenge | Solution |

|---|---|---|

| Softness and Flexibility | Deformation and dimensional errors | Sharp tools, light forces, adequate support |

| High Thermal Expansion | Dimensional variability and shrinkage | Cooling methods, incremental machining |

| Creep (Cold Flow) | Clamping deformation and warping | Custom fixtures, reduced clamping pressure |

| Low Thermal Conductivity | Heat buildup and tool wear | Coolants, polished tools |

Essential Machining Techniques for PTFE

Machining PTFE requires specialized techniques to manage its unique properties, such as softness, low thermal conductivity, and high thermal expansion. This section provides detailed, authoritative guidance on tools, parameters, cooling, and fixturing to achieve optimal results.

1. Cutting Tools

Using the right cutting tools is critical for machining PTFE efficiently. Due to its softness and low friction, PTFE demands sharp tools with specific geometries to produce clean cuts and prevent deformation.

-

Tool Material:

- High-speed steel (HSS) or carbide tools are highly recommended due to their durability and ability to maintain a sharp edge.

- For long runs, polycrystalline diamond (PCD) tools can provide exceptional wear resistance and maintain edge sharpness.

-

Geometry:

- High rake angles (15–20°) are ideal for reducing cutting forces and ensuring smooth material removal.

- Honed cutting edges minimize burr formation and smearing, which are common when machining PTFE.

-

Tool Maintenance:

- PTFE’s tendency to adhere to tools necessitates frequent cleaning to maintain sharpness.

- Regular tool replacement is critical to avoid dragging or compressing the material, which can lead to dimensional inaccuracies.

Pro Tip: Avoid tools with coatings designed for metal machining, such as TiN (Titanium Nitride), as they may increase friction and lead to poor finishes on PTFE.

2. Cutting Parameters

PTFE’s low melting point and high thermal expansion make it essential to use conservative cutting parameters to minimize heat generation and material deformation.

-

Feed Rates:

- Employ low feed rates (0.1–0.3 mm/rev) to ensure precise material removal without tearing.

- Excessively high feed rates can cause the material to push away from the tool, resulting in poor dimensional accuracy.

-

Spindle Speeds:

- Use high spindle speeds (3,000–6,000 RPM, depending on the tool diameter) to enhance surface finish.

- High speeds help minimize cutting forces and reduce heat buildup at the tool-material interface.

-

Depth of Cut:

- Shallow depths of cut (0.5–1 mm per pass) are recommended to avoid excessive material stress and deformation.

- Avoid aggressive cuts, as PTFE’s softness can lead to tearing or incomplete chip formation.

Example: When turning PTFE on a CNC lathe, a spindle speed of 4,000 RPM, a feed rate of 0.2 mm/rev, and a depth of cut of 0.8 mm have been shown to produce optimal surface finishes.

3. Cooling and Lubrication

PTFE’s low thermal conductivity means heat generated during machining does not dissipate effectively, leading to potential melting, smearing, or tool wear. Proper cooling and lubrication are essential to mitigate these issues.

-

Coolant Recommendations:

- Use air cooling or water-based coolants to dissipate heat effectively without contaminating the material.

- Non-aromatic lubricants can enhance surface finish without altering PTFE’s chemical properties.

-

Aromatic Coolants:

- Avoid aromatic or petroleum-based coolants, as they can degrade PTFE and affect its performance in chemically sensitive applications.

-

Dry Machining:

- In certain operations, dry machining with sharp tools and proper feed rates may suffice, especially for simple geometries.

- When dry machining, ensure consistent chip evacuation to prevent material buildup and overheating.

Industry Insight: In gasket manufacturing, compressed air cooling has been shown to reduce surface smearing by up to 40% compared to machining without cooling.

4. Clamping and Fixturing

Due to PTFE’s softness and tendency to deform under pressure, fixturing must be carefully designed to avoid part distortion or creep.

-

Gentle Securing Methods:

- Use soft jaws or custom fixtures that distribute clamping pressure evenly across the workpiece.

- Avoid metal-to-PTFE contact, which can leave marks or indentations on the material.

-

Minimizing Pressure:

- Apply only the necessary amount of clamping force to stabilize the workpiece. Over-tightening can induce creep, leading to permanent deformation.

-

Vacuum Fixtures:

- Vacuum-based fixturing is an excellent option for holding PTFE parts securely without applying mechanical pressure. This is especially useful for thin or delicate components.

Best Practice: When machining thin PTFE sheets, sandwiching the material between sacrificial layers (e.g., plywood or acrylic) can help maintain stability and prevent warping during cutting.

Summary of Best Practices for PTFE Machining

| Aspect | Recommendations |

|---|---|

| Cutting Tools | Use sharp carbide or PCD tools with high rake angles and honed edges. Maintain sharpness through regular cleaning and replacement. |

| Cutting Parameters | Low feed rates, high spindle speeds, and shallow depths of cut to minimize heat and deformation. |

| Cooling | Use air or water-based coolants; avoid aromatic coolants. |

| Fixturing | Use soft jaws, custom fixtures, or vacuum clamps to minimize pressure and prevent creep. |

Specific Machining Operations for PTFE

PTFE machining requires tailored strategies for each type of operation due to the material’s unique properties, such as its low hardness, high thermal expansion, and tendency to creep. Below is a detailed and authoritative guide for specific machining operations to achieve optimal results.

1. Turning

Turning PTFE on a lathe is one of the most common machining operations, but its softness and low thermal conductivity require careful attention to tooling and parameters.

-

Tool Selection:

- Use sharp tools with high rake angles (10–20°) to reduce cutting forces and avoid material smearing.

- Carbide tools with polished cutting edges are ideal for maintaining clean cuts and preventing burr formation.

-

Chip Evacuation:

- Ensure consistent chip evacuation to avoid clogging, as PTFE chips are often stringy and can wrap around the tool or workpiece.

- Use a high-pressure air jet or vacuum system to clear chips during cutting.

-

Cutting Parameters:

- Moderate cutting speeds (500–1,500 RPM depending on the workpiece diameter) and low feed rates (0.1–0.2 mm/rev) help maintain smooth finishes without overheating the material.

Practical Tip: Use coolant sparingly or dry-turn PTFE with sharp tools, as excessive lubrication may cause chips to stick to the cutting tool or workpiece.

2. Milling

Milling PTFE requires precision and proper tool geometry to achieve clean cuts and avoid surface smearing. The softness of PTFE also necessitates strategies to prevent vibration and chatter.

-

Tool Selection:

- Use end mills with polished flutes designed for machining plastics. Polished surfaces reduce friction, improving chip evacuation and minimizing heat generation.

- Single-flute or double-flute end mills are often preferable for PTFE to ensure efficient chip clearance.

-

Cutting Parameters:

- Apply light feed rates (0.05–0.2 mm/tooth) to avoid tearing the material.

- Moderate spindle speeds (3,000–6,000 RPM) help maintain clean cuts without excessive heat buildup.

-

Vibration Control:

- Ensure the workpiece is securely clamped using soft jaws or vacuum fixtures to minimize vibration.

- Avoid aggressive plunges or deep cuts, as PTFE’s softness can amplify chatter.

Industry Insight: When machining large PTFE sheets, reducing vibration with dampened fixtures can improve dimensional accuracy by up to 30%.

3. Drilling

Drilling PTFE requires careful attention to drill geometry and feed pressure to avoid deformation or oversizing of the holes. PTFE’s low hardness makes it susceptible to tearing or material "pushing."

-

Drill Geometry:

- Use drills with a point angle of 90–118° and polished flutes to reduce friction and improve chip evacuation.

- Spiral-flute drills with a high helix angle are effective for soft materials like PTFE.

-

Drilling Technique:

- Apply minimal pressure to avoid compressing the material before the drill penetrates.

- Use peck drilling techniques (intermittent withdrawal) to clear chips and reduce heat buildup.

-

Hole Tolerances:

- PTFE’s thermal expansion can temporarily enlarge holes during drilling. Allow the material to cool before performing final measurements or machining additional features.

Pro Tip: For precise holes, consider undersizing the initial drill and reaming to final dimensions after the material stabilizes.

4. Threading

Threading PTFE is particularly challenging due to its softness and low compressive strength. Special care is required to avoid distortion and achieve durable threads.

-

Taps and Dies:

- Use sharp, high-speed steel (HSS) taps and dies with generous clearances to prevent material deformation.

- Avoid standard taps designed for metals, as they can compress PTFE instead of cutting clean threads.

-

Thread Inserts:

- For applications requiring high load-bearing capacity or frequent disassembly, consider using threaded inserts (e.g., Helicoils). These provide greater strength and durability for threaded connections in PTFE components.

-

Cutting Technique:

- Use slow, controlled rotations with minimal torque to avoid stripping or damaging the threads.

- Lubrication is optional but can aid in smoother threading by reducing friction.

Real-World Application: Threaded PTFE components used in chemical processing often rely on inserts to withstand the stress of repeated assembly without compromising the integrity of the material.

Summary of Machining Operations for PTFE

| Operation | Key Challenges | Best Practices |

|---|---|---|

| Turning | Surface smearing, inconsistent chips | Use sharp tools, ensure chip evacuation, and apply moderate speeds and low feed rates. |

| Milling | Vibration, poor chip clearance | Use polished end mills, light feed rates, and moderate spindle speeds. |

| Drilling | Hole deformation, chip buildup | Use drills with polished flutes, minimal pressure, and peck drilling techniques. |

| Threading | Weak threads, material compression | Use sharp taps and dies, consider threaded inserts, and apply controlled rotations with low torque. |

Achieving Precision and Tolerances in PTFE Machining

Achieving precision and maintaining tight tolerances in PTFE machining can be particularly challenging due to the material's unique properties. PTFE's softness, high thermal expansion, and tendency to deform under load necessitate specialized strategies to ensure dimensional accuracy and high-quality results.

Challenges of Achieving Tight Tolerances

PTFE's inherent characteristics, such as:

- Thermal Expansion: Its high coefficient of thermal expansion means dimensions can change significantly with temperature fluctuations during machining.

- Softness: PTFE’s low hardness makes it prone to deformation during clamping or cutting.

- Creep (Cold Flow): Under constant stress, PTFE can slowly deform over time, making it difficult to maintain long-term dimensional stability.

These properties make it difficult to achieve tolerances as tight as ±0.001", which are often required in applications such as seals, gaskets, and medical components.

Strategies for Precision Machining

1. Stress Relieving Before Machining

PTFE often retains internal stresses from its manufacturing process (e.g., extrusion or molding). These stresses can cause dimensional instability during machining.

-

Process:

- Heat the material to a controlled temperature below its melting point (typically 100–120°C) and hold it for several hours to relieve internal stresses.

- Allow the material to cool gradually to room temperature before machining.

-

Benefits:

- Reduces the likelihood of warping or dimensional changes during cutting.

- Improves stability and consistency in the final product.

Example: In high-precision aerospace applications, stress relieving is a standard practice to ensure consistent part performance under varying thermal and mechanical conditions.

2. Pre-Machining Oversize Parts

Machining PTFE in stages by pre-machining oversized parts and finishing with precise cuts helps mitigate issues caused by thermal expansion and creep.

-

Steps:

- Rough machine the part to an oversized shape, leaving a small margin (e.g., 0.5–1.0 mm) for the final cut.

- Allow the part to stabilize by cooling to room temperature.

- Perform a finishing cut to achieve the desired dimensions and tolerances.

-

Advantages:

- Compensates for dimensional changes caused by heat and stress during the initial machining.

- Allows for finer control over the final dimensions.

Pro Tip: Ensure consistent environmental conditions (temperature and humidity) during the machining process to minimize external factors influencing part dimensions.

3. Precise Measurements and Quality Control

Accurate measurement and stringent quality control are essential to maintaining precision and ensuring parts meet specification requirements.

-

Measurement Techniques:

- Use non-contact measurement tools such as laser scanners or coordinate measuring machines (CMMs) to avoid compressing the soft PTFE surface during inspection.

- Calipers and micrometers with rounded tips can also be used, but apply minimal pressure to prevent deformation.

-

Quality Control Best Practices:

- Inspect parts at multiple stages of machining (e.g., after rough cuts, intermediate passes, and final cuts).

- Monitor dimensional stability over time to account for creep or thermal relaxation in critical applications.

Industry Insight: Medical device manufacturers often implement 100% inspection of PTFE components to ensure compliance with strict regulatory standards, given the material's sensitivity to dimensional changes.

Summary of Best Practices for Achieving Precision

| Challenge | Solution |

|---|---|

| Thermal Expansion | Use stress relieving and allow for cooling periods during machining. |

| Softness | Pre-machine oversized parts and use sharp tools for final precision cuts. |

| Creep (Cold Flow) | Employ custom fixtures and minimize clamping forces to reduce stress-induced deformation. |

| Measurement Accuracy | Use non-contact tools or apply minimal pressure with traditional instruments. |

Surface Finishing Techniques for PTFE

Surface finishing is a critical step in PTFE machining, as it directly impacts the performance and aesthetics of the final product. PTFE’s inherent softness and low friction coefficient present unique challenges, requiring specialized techniques to achieve a smooth, functional finish.

Surface Finishing Methods

1. Polishing

Polishing is often employed to enhance the surface smoothness of PTFE components, particularly for applications requiring low friction or minimal surface imperfections.

-

Process:

- Use fine-grit abrasives or polishing pads to gently remove surface irregularities.

- Apply light pressure to avoid deforming the material or creating heat that may cause smearing.

-

Applications:

- Polished PTFE surfaces are ideal for seals, gaskets, and bearings, where low-friction contact is critical.

-

Limitations:

Excessive polishing can damage PTFE’s structure, reducing its thickness and altering dimensional accuracy.

Pro Tip: Use water or air cooling during polishing to minimize heat buildup and maintain the integrity of the PTFE surface.

2. Buffing

Buffing is another effective method to improve surface finish, particularly for achieving a satin or semi-gloss appearance on PTFE parts.

-

Process:

- Use soft, lint-free buffing wheels with minimal abrasive compounds to avoid over-removal of material.

- Rotate the part consistently to ensure uniform surface treatment.

-

Benefits:

- Buffing can remove minor scratches or blemishes left from machining while preserving the part’s dimensions.

- It is less aggressive than polishing, making it suitable for thin-walled or delicate PTFE components.

3. Tumbling

Tumbling is a bulk finishing process often used for smaller PTFE components. It smooths edges and surfaces by exposing parts to controlled abrasive media in a rotating or vibrating container.

-

Process:

- Use lightweight media, such as plastic or ceramic beads, to prevent excessive wear on the soft PTFE surface.

- Select slow tumbling speeds to reduce the risk of deformation or surface damage.

-

Applications:

- Ideal for finishing small, high-volume parts such as washers or bushings.

- Tumbling can round off sharp edges and improve overall part consistency.

-

Cautions:

- Prolonged tumbling can lead to over-rounding of features or dimensional changes, so processing times should be carefully monitored.

Limitations of Surface Finishing for PTFE

-

Softness of PTFE:

- PTFE’s low hardness makes it difficult to achieve highly polished or mirror-like finishes. Excessive finishing efforts can lead to material removal, altering part dimensions.

-

Low Surface Energy:

- PTFE’s low surface energy reduces its ability to bond with other materials or coatings, which can limit the effectiveness of certain finishing techniques.

Practical Insight: For applications where a high-polish finish is required, consider using PTFE blends or composites (e.g., PTFE with glass fillers), as they may offer improved finishing characteristics.

Surface Treatments for Enhanced Functionality

Light Etching

Etching is commonly used to modify PTFE surfaces for improved adhesion in bonding or coating applications.

-

Process:

- A chemical etching solution (often sodium-based) is applied to the PTFE surface to create microscopic roughness.

- Rinse and dry the part thoroughly after etching to remove residual chemicals.

-

Applications:

- Etched PTFE is used in applications where the material needs to bond with adhesives or other materials, such as composite components or laminated gaskets.

-

Precautions:

- Etching can slightly alter the material’s surface properties, so it should be performed only on areas where bonding is required.

- Proper handling and safety protocols must be followed due to the use of strong chemicals.

Industry Example: Chemically etched PTFE is widely used in the electronics industry for producing flexible circuits where adhesive bonding is critical.

Summary of Surface Finishing Techniques

| Method | Best Applications | Key Advantages | Limitations |

|---|---|---|---|

| Polishing | High-friction or aesthetic surfaces | Smoothens surface; reduces friction | Excessive polishing may alter dimensions. |

| Buffing | Thin-walled or delicate components | Gentle; removes minor blemishes | Less aggressive than polishing. |

| Tumbling | Small, high-volume parts | Smooths edges; ensures consistency | May over-round delicate features. |

| Etching | Bonding or coating applications | Enhances adhesion | Alters surface properties locally. |

Design Considerations for PTFE Parts

Designing PTFE parts requires careful attention to the material's unique characteristics to ensure manufacturability, functionality, and long-term performance. PTFE’s softness, low compressive strength, and tendency to deform under load make it essential to optimize design features to avoid common pitfalls during machining and application.

Key Design Principles

1. Avoid Sharp Corners

Sharp corners in PTFE parts can create stress concentrations, leading to deformation or cracking during machining or use.

-

Recommendations:

- Replace sharp corners with generous radii or fillets to distribute stress evenly across the part.

- Radii as small as 1.5–2 times the wall thickness are typically sufficient to improve structural integrity.

-

Benefits:

- Enhances machinability by reducing the risk of tool chatter or tearing.

- Improves the durability of the part, particularly in applications involving dynamic loads or high-pressure environments.

Example: In sealing applications, PTFE gaskets with rounded edges are less likely to develop stress fractures during installation or use.

2. Minimize Stress Concentrations

PTFE’s low modulus of elasticity makes it highly susceptible to stress-related deformation. Careful design can mitigate this issue.

-

Strategies:

- Incorporate uniform wall thickness throughout the part to prevent localized stress during machining or use.

- Avoid abrupt transitions in geometry; use gradual tapers or stepped features instead.

-

Applications:

- Thin-walled PTFE components, such as bushings or liners, benefit from consistent wall thickness to maintain dimensional stability under load.

Pro Tip: For load-bearing parts, consider adding reinforcement features, such as ribs or embedded inserts, to reduce stress without significantly increasing material usage.

3. Account for Creep (Cold Flow)

Creep, or the tendency of PTFE to deform under sustained load, can lead to dimensional changes over time. Design adjustments can minimize its impact.

-

Design Adjustments:

- Avoid designs with narrow or unsupported sections that are prone to sagging or warping under load.

- Add support structures or thicker walls in areas subject to prolonged mechanical stress.

-

Example: PTFE components used in flange connections often include embedded metal rings to maintain structural integrity under clamping forces.

4. Allow for Thermal Expansion

PTFE’s high coefficient of thermal expansion means it expands significantly with temperature changes. Design features should accommodate this behavior.

- Recommendations:

- Include expansion gaps or clearance tolerances in assemblies to allow for dimensional changes without compromising performance.

- Avoid interference fits in high-temperature applications unless secondary support features, such as locking rings, are used.

Industry Insight: In applications like chemical processing, PTFE valve seats are designed with expansion grooves to ensure proper sealing across a wide temperature range.

5. Optimize Machinability

Design features should be tailored to simplify machining processes while maintaining part functionality.

- Tips for Machinability:

- Avoid overly complex geometries that require intricate machining operations.

- Use standard thread sizes and hole dimensions wherever possible to reduce tooling requirements.

- Design features with sufficient clearance for tool access, particularly in internal cavities or threaded areas.

Practical Example: Simple design modifications, such as adding chamfers to entry points for holes or threads, can improve tool engagement and reduce machining time.

Additional Considerations

Material Selection

While pure PTFE is widely used, certain applications may benefit from PTFE composites (e.g., PTFE filled with glass, carbon, or bronze). These materials offer enhanced strength, reduced creep, and improved wear resistance.

Surface Treatments

For applications requiring adhesive bonding or coatings, include etched surfaces or bonding-friendly areas in the design.

Summary of Design Considerations

| Design Aspect | Best Practices | Benefits |

|---|---|---|

| Sharp Corners | Use generous radii and fillets. | Reduces stress concentrations and machining issues. |

| Stress Concentrations | Ensure uniform wall thickness and smooth transitions. | Improves durability and stability. |

| Creep (Cold Flow) | Add support structures and avoid narrow, unsupported sections. | Minimizes long-term deformation. |

| Thermal Expansion | Include expansion gaps and avoid tight fits in high-temperature applications. | Accommodates dimensional changes. |

| Machinability | Simplify geometries, use standard features, and ensure tool access. | Reduces machining complexity and cost. |

Safety Precautions When Machining PTFE

Machining PTFE requires strict adherence to safety protocols to protect operators and maintain a safe working environment. While PTFE is a chemically inert material, its machining can generate fumes, particulates, and physical risks that must be managed effectively. Below is a detailed guide to essential safety measures.

1. Ventilation and Fume Management

During machining, PTFE may release fumes, particularly if excessive heat is generated. These fumes can contain potentially harmful compounds such as fluorinated gases that pose risks to respiratory health.

-

Ventilation Systems:

- Ensure the workspace is equipped with an efficient local exhaust ventilation (LEV) system to capture and remove fumes directly at the source.

- Install high-efficiency particulate air (HEPA) filters in ventilation systems to trap fine particles and ensure clean air circulation.

-

Temperature Control:

- Maintain cutting tools at optimal speeds and feeds to minimize heat generation and prevent the material from reaching decomposition temperatures (above 260°C/500°F).

- Use coolants like compressed air or water-based solutions to keep machining temperatures within a safe range.

Pro Tip: Regularly inspect and maintain ventilation systems to ensure peak performance and compliance with occupational safety standards.

2. Personal Protective Equipment (PPE)

Operators must wear appropriate PPE to protect against potential hazards, including particulates, fumes, and physical injury.

-

Respiratory Protection:

- Use a respirator with activated carbon filters if ventilation alone does not adequately mitigate fumes.

- Disposable dust masks may suffice for short-term operations, but they are less effective against prolonged exposure.

-

Eye Protection:

- Wear safety goggles or wraparound safety glasses to shield the eyes from flying chips or particulates generated during cutting or drilling.

-

Hand Protection:

- Use heat-resistant gloves to protect against accidental contact with hot tools or materials.

- Choose gloves that provide dexterity while preventing chemical or physical exposure.

-

Hearing Protection:

- Machining operations often involve loud equipment; earplugs or earmuffs are recommended to safeguard hearing during extended periods.

3. Safe Handling of PTFE Waste

Machining PTFE generates chips and fine particles that need to be handled and disposed of carefully to avoid environmental or health risks.

-

Chip Collection:

- Use vacuum systems with HEPA filters to collect chips and particulates directly from the cutting area.

- Avoid sweeping or blowing chips, as this can disperse fine particles into the air.

-

Waste Disposal:

- Dispose of PTFE waste according to local regulations, as fluorinated materials may require specialized handling and recycling processes.

- Separate PTFE waste from other materials to prevent contamination and facilitate proper recycling or disposal.

Industry Insight: In sectors like aerospace or medical manufacturing, where PTFE is used extensively, automated waste collection systems are employed to maintain a clean and compliant workspace.

4. Fire and Heat Safety

PTFE is non-flammable under normal conditions but can emit toxic fumes if exposed to extremely high temperatures or open flames.

-

Fire Precautions:

- Keep heat sources, such as welding or open flames, away from PTFE machining areas.

- Ensure fire extinguishers rated for chemical fires are readily accessible in the workspace.

-

Tool Temperature Monitoring:

- Regularly inspect cutting tools and ensure they are not overheating during prolonged operations.

- Use infrared thermometers to monitor tool temperatures when machining at high speeds.

5. Operator Training and Awareness

Educating operators on the unique properties of PTFE and the associated risks is vital for maintaining safety standards.

-

Training Topics:

- Proper tool setup and machining techniques to minimize heat generation.

- Identifying signs of overheating or poor ventilation, such as visible smoke or unusual odors.

- Emergency procedures for handling accidental exposure to fumes or particulates.

-

Safety Drills:

- Conduct regular safety drills to ensure all operators are familiar with evacuation procedures and the use of PPE and ventilation systems.

Summary of Safety Precautions

| Safety Measure | Details |

|---|---|

| Ventilation | Use LEV systems with HEPA filters; maintain proper airflow to capture fumes and particles. |

| Respiratory Protection | Wear respirators with activated carbon filters for prolonged exposure to machining fumes. |

| Eye and Hand Protection | Use safety goggles and heat-resistant gloves to protect against chips, particulates, and heat. |

| Waste Management | Collect and dispose of PTFE chips according to local environmental regulations. |

| Fire Safety | Avoid heat sources near PTFE; monitor tool temperatures to prevent excessive heating. |

| Operator Training | Educate operators on machining risks, proper tool use, and emergency procedures. |

Conclusion: Mastering PTFE Machining for Efficiency and Precision

PTFE machining, while challenging, offers immense rewards for industries requiring high-performance components. Its exceptional properties—such as chemical inertness, low friction, and thermal stability—make it indispensable in aerospace, medical, and chemical processing applications. However, success lies in mastering its unique characteristics.

By understanding the intricacies of PTFE’s softness, thermal expansion, and creep, and by implementing tailored machining techniques, manufacturers can achieve superior precision and functionality. From selecting the right tools and cutting parameters to prioritizing safety and design considerations, each step contributes to efficient and accurate outcomes.

Final Words of Advice

Experimentation and adaptability are key when machining PTFE. Optimize parameters to suit specific project needs and rely on rigorous quality control to ensure each part meets exact specifications. Take advantage of best practices shared in this guide to transform challenges into opportunities for innovation.

If you’re seeking expert PTFE machining solutions tailored to your unique requirements, look no further. Contact PROMACHINED today to collaborate on creating precise, reliable components that exceed expectations.

FAQ:

Is PTFE hard to machine?

Yes, PTFE is challenging to machine due to its unique properties, such as softness, high thermal expansion, and creep. These characteristics can lead to deformation, smearing, and difficulty maintaining tight tolerances. However, with sharp tools, proper cutting parameters, and cooling techniques, it can be machined effectively.

What are the machining tolerances for PTFE?

PTFE can achieve tolerances as tight as ±0.001" with proper machining practices. However, achieving such precision requires incremental cuts, stress-relieved material, and strict quality control due to PTFE’s high thermal expansion and creep.

Which is better: PTFE or Teflon?

PTFE and Teflon are the same material. "Teflon" is a brand name by Chemours, while "PTFE" refers to the generic polymer. Both have identical properties, but choosing branded Teflon may provide additional assurance of quality and consistency in specific applications.

What are the processing methods of PTFE?

PTFE can be processed using various methods, including:

- CNC Machining: For precise parts like seals and gaskets.

- Compression Molding: To create large blocks or preforms for further machining.

- Extrusion: For rods, tubes, and sheets.

- Chemical Etching: To prepare surfaces for bonding with adhesives or coatings.

Each method is chosen based on the application’s specific requirements and desired final product.