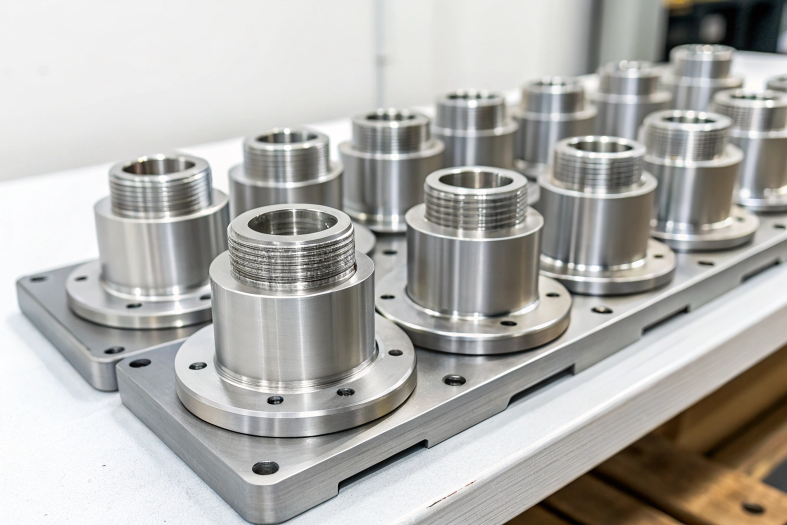

CNC machinists frequently encounter challenges like tool wear, machine calibration errors, and software glitches, which can disrupt production and affect product quality. The pressure to maintain precision while meeting tight deadlines exacerbates these issues, and the need to stay updated on new technologies adds further stress. To overcome these challenges, machinists must prioritize regular maintenance, invest in quality tools, and continuously enhance their skills through training, ensuring optimal performance and consistent, high-quality results.

Direct Answer :

The most common problems CNC machinists face include tool wear, machine calibration errors, incorrect programming, material inconsistencies, and inadequate maintenance. These challenges can be mitigated with regular machine maintenance, proper training, and high-quality materials to ensure accurate and efficient operations in CNC machining processes.

1. Equipment Issues

Machine Failures:

CNC machines are complex systems, and their breakdowns can significantly impact productivity. Some of the most common machine failures include:

-

Spindle Failures: The spindle is crucial for rotating the cutting tool. If it malfunctions, it can result in poor tool engagement, excessive vibrations, and even tool crashes. Symptoms of spindle problems can include noise, overheating, or erratic motion.

Real-World Example: At a high-end automotive parts manufacturer, frequent spindle failures led to production delays. They adopted a predictive maintenance system that monitored spindle temperature, vibration, and performance data. This system alerted operators when a spindle was likely to fail, allowing them to replace it before it caused a production stoppage.

Solution: Regular lubrication, vibration analysis, and temperature monitoring can extend the lifespan of the spindle. For machines with high workloads, consider upgrading to higher-quality spindles that can withstand the wear and tear better.

-

Servo Motor Malfunctions: Servo motors control the movement of the CNC machine’s axes. If the motor malfunctions, the machine will lose positional accuracy, causing misalignment in the cutting process.

Solution: Check the motors regularly for wear and tear, especially when the machine operates at high speeds. It’s also important to ensure that the electrical systems powering the motors are stable. Using vibration analysis and motor diagnostics software can help identify potential issues before they become major problems.

-

Tool Changer Failures: Many CNC machines use automatic tool changers (ATCs) to swap tools during the machining process. When the ATC fails, it can cause delays, requiring manual intervention to change tools.

Solution: Regularly inspect the tool changer for wear and keep it clean. Lubrication is also key in preventing rust or friction issues that could cause failure.

Regular Maintenance and Inspection:

Routine maintenance can help reduce unexpected machine failures.

- Lubrication: Keep machine parts well-lubricated to avoid friction and heat buildup. Use high-quality lubricants tailored to your machine’s requirements.

- Alignment Checks: Regularly verify the alignment of critical machine components, such as the table, spindle, and axis movements. Misalignment can lead to errors and degradation of machine parts.

- Cleaning: Keep the machine clean of debris, chips, and coolant build-up. For example, dirt buildup on linear guides can cause a loss of precision over time.

Solution: Develop a daily, weekly, and monthly maintenance schedule and stick to it. Keep an eye on parts that are subject to more wear, like the spindle or tool changer.

2. Programming and Code Errors

Programming Mistakes:

Programming errors are one of the most common causes of machining problems. Some examples include:

-

Incorrect Tool Paths: Tool paths that are not programmed correctly can cause parts to be machined incorrectly. This could include overlapping paths or cutting too deeply into the material.

Real-World Example: A machinist at a precision engineering firm forgot to account for tool offset when programming a CNC machine for a batch of aerospace components. This led to incorrect cuts, forcing the company to scrap the entire batch and reorder the material, costing thousands of dollars.

Solution: Before running the machine, simulate the tool paths using software like CAD/CAM simulations. This will show any potential collisions, toolpath errors, or areas where tool wear may cause issues. Use specialized tools for multi-axis machines to verify the tool paths are optimized.

-

Wrong Feed Rates: Feed rate errors can cause serious issues, especially when dealing with harder materials. A slow feed rate can result in inefficient machining, while a fast feed rate can cause tool wear or even damage to the machine.

Solution: Use recommended feed rates for each material and cutting tool. Most CNC machines come with pre-programmed feed rates based on material types. Additionally, monitoring tool wear can help adjust feed rates to match the condition of the tool.

Program Debugging:

When an error occurs, debugging becomes essential.

-

Interpreting Error Codes: CNC machines often display error codes when something goes wrong. Understanding these codes is crucial to resolving the issue quickly. For example, an "E06" code might indicate an issue with the machine’s encoder or feedback loop, while an "E09" code might point to a problem with the toolchanger.

Solution: Always refer to the machine’s user manual and documentation when troubleshooting. For recurring issues, keep a log of error codes and resolutions to identify patterns and prevent future issues.

3. Precision and Accuracy Problems

Tool Wear:

Tool wear is one of the biggest factors affecting precision. As tools wear down, they lose sharpness, leading to inconsistent cuts.

-

Tool Wear Indicators: You might not always notice tool wear until it’s too late, but there are indicators, such as increased cutting force, vibrations, or heat buildup. Over time, tool wear can cause the dimensions of the part to drift out of tolerance.

Solution: Implement tool wear detection systems if your CNC machine supports them. These systems monitor changes in cutting force or vibration, alerting operators when a tool needs to be replaced. Additionally, tracking tool life and usage can help you predict when tools are likely to fail.

Part Tolerances:

High-precision parts require tight tolerances, and when CNC machines are not calibrated properly, parts may end up out of spec.

-

Thermal Expansion: During machining, heat generated by cutting can cause both the material and machine components to expand. This can lead to slight dimensional changes that are difficult to control.

Solution: Use coolant systems to keep temperatures consistent. For very tight tolerances, consider using thermal compensation software or machine setups that take thermal effects into account.

-

Environmental Conditions: Environmental factors, like temperature and humidity, can also impact the precision of CNC machines. In high-humidity environments, parts can absorb moisture, changing their dimensions during machining.

Solution: Control the environment around your CNC machines. Use climate control in the workspace to minimize fluctuations in temperature and humidity.

4. Material Problems

Material Selection and Compatibility:

Choosing the wrong material or failing to account for material characteristics can cause issues during the machining process.

-

Hardness Mismatch: Hard materials such as titanium or hardened steels can wear out tools more quickly than softer metals like aluminum.

Real-World Example: A CNC shop that primarily worked with aluminum tried machining a batch of stainless steel parts without upgrading their tooling. The tools wore out quickly, and the part finishes were subpar. They had to stop production to switch to carbide inserts, which were more suitable for stainless steel.

Solution: Always select the right material for the job and ensure your cutting tools are compatible. Consult with material suppliers and tool manufacturers to choose the best combination for each project.

Material Handling and Preparation:

How materials are handled before machining can have a significant impact on machining success.

-

Contaminants: Contaminants like dirt, oil, or rust can damage the cutting tool, affect surface finishes, and reduce the overall quality of the parts.

Solution: Ensure materials are properly cleaned before machining. Use ultrasonic cleaning or solvent-based cleaning methods to remove contaminants.

5. Operator Errors

Setup Mistakes:

Even experienced machinists can make setup errors. These mistakes can result in poor-quality parts or even damage to the machine.

-

Improper Zero Point Setup: Incorrectly setting the zero point (origin) can lead to parts being machined off-center, causing misalignment and waste.

Solution: Always use precise tools, like dial indicators or laser probes, to ensure the workpiece is correctly aligned. Verify the setup before starting the machining process, and consider using a work offset system for accuracy.

Human Errors:

Human mistakes, such as fatigue, distractions, or lack of experience, can lead to errors that impact machining quality.

Solution: Provide thorough training for operators, focusing on both technical skills and safety procedures. Encourage operators to take regular breaks to avoid fatigue, and always double-check work setups before starting.

6. Coolant and Lubrication Issues

Insufficient Coolant Flow or Incorrect Coolant Type:

Coolant is crucial for controlling heat, removing chips, and preventing tool wear. If coolant flow is insufficient or the wrong type is used, the machining process can suffer.

-

Heat Build-up: Without adequate coolant flow, the cutting process will generate excessive heat, causing tool wear and thermal expansion of materials.

Solution: Regularly check coolant systems to ensure they are functioning properly. Invest in high-quality coolants that are formulated for your specific machining applications.

Lubrication Failures:

Machines with high-speed components need proper lubrication to maintain smooth operation and reduce wear. Lack of lubrication can cause friction, overheating, and eventual machine failure.

Solution: Make sure to lubricate moving parts regularly, especially high-speed spindles and tool changers. Use high-performance lubricants designed for your specific machine and operational environment.

7. External Factors

Environmental Factors:

Environmental conditions can significantly impact CNC machining accuracy. High humidity, temperature fluctuations, or even dust can all cause variations in the machine’s performance.

Solution: Use climate-controlled environments for critical CNC operations. If that’s not possible, at least isolate the machine from environmental disturbances as much as possible.

Power Supply Issues:

Power fluctuations can lead to machine malfunctions, especially in sensitive electronics. Power surges or dips can cause CNC machines to shut down unexpectedly, or worse, lead to permanent damage.

Solution: Install power surge protectors and use backup power systems (UPS) to ensure the CNC machines remain stable and operational even during power fluctuations.

8. Technological Upgrades and Training

Adapting to New Technologies:

With the rapid advancement of CNC technologies, keeping up can be a challenge. Newer machines may offer faster speeds, improved accuracy, or enhanced capabilities, but these require different skill sets and software.

Solution: Continuously invest in upgrading both your machines and your team’s skillsets. Stay updated on emerging trends, such as the integration of IoT sensors for predictive maintenance or AI-powered quality control systems.

Continuous Learning:

CNC machinists must keep learning to stay on top of their game. As technology changes, so too do best practices in programming, operation, and maintenance.

Solution: Provide ongoing training opportunities, whether through workshops, online courses, or industry conferences. Encourage a culture of learning within the workplace to help employees adapt to new challenges.

Conclusion

CNC machining is both an art and a science, requiring skilled operators, well-maintained equipment, and a keen eye for detail. The challenges faced by CNC machinists can vary from technical machine malfunctions to human errors, but by understanding these common problems and implementing proactive solutions, you can enhance your operations, improve part quality, and reduce downtime.

As the industry continues to evolve, staying informed about new technologies, materials, and best practices will be key to staying competitive in the world of CNC machining.

By addressing these common CNC machining challenges systematically, you can ensure a more efficient, accurate, and cost-effective machining process. Whether you're a seasoned machinist or new to the field, these insights will help you overcome obstacles and maintain optimal machine performance.

FAQ:

What are the common problems in CNC?

- Machine Failures: Common issues include spindle breakdowns, servo motor malfunctions, and tool changer failures. Regular maintenance and diagnostics can help minimize these problems.

- Programming Errors: Mistakes in tool paths, feed rates, and other parameters can lead to machining defects. Simulation software can help reduce these errors before production.

- Precision Issues: Tool wear and part tolerances can lead to dimensional inaccuracies. Regular tool maintenance and careful calibration can prevent these issues.

- Coolant and Lubrication Problems: Insufficient coolant flow or improper lubrication can cause overheating, tool wear, and machine malfunction.

- Operator Errors: Human mistakes in machine setup, tool selection, and program loading can lead to inefficiencies or part defects.

What is the life expectancy of CNC?

The life expectancy of a CNC machine typically ranges from 10 to 20 years depending on usage, maintenance, and the type of machine. With regular maintenance and proper care, some high-end CNC machines can last beyond 20 years, while others may experience significant wear and tear after 10 years, especially in high-volume operations.

What are 3 disadvantages of a CNC machine?

- High Initial Cost: CNC machines can be expensive to purchase and install, requiring significant capital investment.

- Skilled Labor Requirement: Although CNC machines automate many processes, operators still need specialized training to handle programming, troubleshooting, and maintenance.

- Maintenance Costs: Regular maintenance and occasional repairs can be costly, especially if parts need replacement or major servicing.

What are the hazards of CNC operators?

- Cutting Tool Injuries: Operators are at risk of being injured by sharp cutting tools, especially if safety precautions aren't followed.

- Noise Exposure: Prolonged exposure to the high noise levels produced by CNC machines can lead to hearing damage over time.

- Flying Debris: During machining, chips or fragments from the material being cut can fly off, posing a risk to operators' eyes or skin.

- Electrical Hazards: Improper handling or malfunction of the electrical components can lead to electrical shocks or fires.

- Inhalation of Dust and Fumes: CNC operations, especially in materials like metals or plastics, can produce harmful dust or fumes that can be hazardous if proper ventilation or respirators are not used.