CNC machining for prototyping comes with its challenges. When developing new products or parts, companies often struggle to find methods that are both accurate and efficient. Traditional prototyping techniques may not meet the precision or material needs of complex designs, leading to delays and increased costs.

However, CNC machining effectively solves these issues. It offers high precision, quick turnaround, and a wide range of material options, allowing designers to rapidly test, iterate, and refine designs without wasting resources, thus speeding up the development process.

Direct Answer:

Yes, CNC machining is ideal for prototyping. It provides precise, fast, and cost-effective production, enabling rapid iterations with various materials and complex geometries, making it an excellent choice for testing and refining designs.

Overview of CNC Machining

CNC (Computer Numerical Control) machining is a cutting-edge manufacturing process that utilizes computer software to control the movement of machine tools such as lathes, mills, and routers. CNC machines are capable of executing complex, high-precision tasks by following a pre-programmed set of instructions, typically derived from CAD (Computer-Aided Design) files. The process offers unparalleled accuracy and repeatability, making it indispensable for industries that require tight tolerances and intricate designs.

CNC machining has evolved over decades from manual machining, driven by technological advancements in automation and computational control. Today, it plays a pivotal role not just in full-scale production, but also in prototyping, providing a bridge between design concepts and mass manufacturing. It enables manufacturers to produce functional, tested prototypes quickly, ensuring that they meet the rigorous demands of industries such as aerospace, automotive, medical devices, and electronics.

Prototyping Needs

Prototyping is the cornerstone of product development, offering a tangible representation of a conceptual design. For manufacturers, a prototype is more than just a mock-up—it is a crucial tool for testing form, fit, function, and performance under real-world conditions. Prototypes allow designers and engineers to verify design assumptions, identify potential flaws, and iterate on a design before it goes into mass production.

The prototyping process demands speed, precision, and flexibility. For rapid iterations, the ability to produce multiple prototypes with high accuracy and material fidelity is essential. As the complexity of the part increases, so too does the need for a prototyping method that can handle intricate geometries, tight tolerances, and material performance. These factors are where CNC machining shines, as it allows for quick adjustments to designs and produces parts that closely mimic the final production units.

Advantages of CNC Machining for Prototyping

Precision and Consistency

CNC machining is renowned for its precision and ability to meet tight tolerances, often within fractions of a millimeter. This level of accuracy is indispensable when prototyping parts that need to function exactly as planned. For industries like aerospace, medical devices, and electronics, even the slightest deviation in dimensions can lead to costly mistakes or failures in functionality. CNC machining eliminates human error, ensuring that every part is identical, which is crucial for testing prototypes against specific performance criteria.

Advanced CNC machines can handle complex, multi-axis movements, allowing for the creation of intricate features, internal geometries, and complex shapes. This precision is essential when producing prototypes that need to function under real-world conditions, where functionality, durability, and reliability are tested. Parts manufactured through CNC machining undergo less variation compared to manual processes or lower-precision technologies, which makes it the ideal choice for critical prototyping.

Material Versatility

CNC machining's capability to work with a vast array of materials is another key advantage in prototyping. Unlike some rapid prototyping methods, such as 3D printing, which may be limited to a narrower range of materials, CNC machining can work with nearly any material—metals, plastics, ceramics, composites, and even hybrid materials. The versatility in materials allows manufacturers to test prototypes under the exact conditions that the final product will face, including load-bearing, wear resistance, heat resistance, and corrosion resistance.

Common materials used in CNC prototyping include:

- Metals: Aluminum, steel, titanium, brass, copper, and alloys.

- Plastics: ABS, nylon, polycarbonate, and polyetheretherketone (PEEK).

- Composites: Carbon fiber, fiberglass, and resin-infused materials.

This flexibility also extends to surface finishes, allowing prototypes to be produced with smooth surfaces or textures that mimic the final product, contributing to more accurate testing and evaluation.

Small Batch Production

CNC machining is inherently suited to small-batch production, making it an ideal option for prototyping. Unlike injection molding, which often requires costly molds and tooling, CNC machining only requires the setup of the machine, reducing initial costs. This makes CNC machining highly cost-effective for low-volume runs of prototypes—whether you're testing one or ten parts. Small manufacturers and startups especially benefit from this flexibility, as they can make design iterations without large upfront investments in tools or molds.

For complex, custom, or highly specialized parts, CNC machining offers the advantage of speed and precision without the need for extensive tooling. Prototypes can be produced quickly and accurately, with the flexibility to adjust or modify designs as needed.

Drawbacks of CNC Machining for Prototyping

Higher Costs

While CNC machining offers a high degree of precision and versatility, it can be more expensive than other prototyping techniques, such as 3D printing or traditional handcrafting. The cost of CNC machining depends on factors such as the material used, machine time, complexity of the part, and the need for post-processing steps like finishing, coating, or assembly. For large quantities, CNC machining remains cost-effective, but for very low-volume production, the per-unit cost can be high.

Additionally, while CNC machining does not require the creation of molds like injection molding, the setup costs for CNC machines, including programming and tooling, can still be significant, especially for complex parts. As a result, for companies focusing solely on rapid, low-cost prototyping, alternative methods like 3D printing or laser cutting might be more suitable.

Longer Lead Times

Compared to methods like 3D printing, CNC machining generally has longer lead times. Setting up the CNC machine, selecting the right tools, preparing the material, and executing the machining process can take longer, especially when complex features or multi-step processes are involved. CNC machines also require regular maintenance and calibration, which can add additional time to the overall prototyping timeline.

For quick-turnaround prototyping, 3D printing may be more appropriate, especially when time constraints are a priority. However, for prototypes that require high precision, material durability, or performance testing, CNC machining's longer lead time is often justified.

Comparison with Other Prototyping Techniques

CNC Machining vs. 3D Printing

While both CNC machining and 3D printing are popular choices for prototyping, they differ significantly in their strengths and weaknesses.

- CNC Machining: Ideal for high-precision, functional prototypes that need to replicate the final product's material properties. CNC machining excels at producing complex, durable parts with excellent surface finishes and tight tolerances. It works well for materials that require specific performance characteristics, such as metals and composites.

- 3D Printing: Best suited for quick, low-cost, conceptual prototypes. 3D printing can produce parts rapidly and cost-effectively, particularly for simpler geometries. However, it often sacrifices precision and material strength, making it less suitable for parts that need to undergo functional testing or have high mechanical properties.

Ultimately, CNC machining is preferred for prototypes that need to function in real-world applications, while 3D printing is better for early-stage prototypes and visual models.

CNC Machining vs. Casting and Injection Molding

When comparing CNC machining to traditional manufacturing processes like casting and injection molding, CNC machining stands out for its speed, flexibility, and lower initial cost for prototypes. Both casting and injection molding are excellent for high-volume production, but they require expensive molds and tooling that may not be feasible for small or early-stage production runs.

- Casting and Injection Molding: These processes are ideal for mass production of parts with complex shapes and high quantities. However, they require significant upfront investment in mold creation and are not as flexible when it comes to design changes or small production runs.

- CNC Machining: CNC offers more flexibility, allowing for quick changes to designs without the need for new molds or tooling. It is perfect for small batch runs and highly customized prototypes.

For low to medium-volume production and complex prototypes, CNC machining is often a better choice due to its cost-effectiveness and quick turnaround times.

Real-World Examples of CNC Machining for Prototyping

-

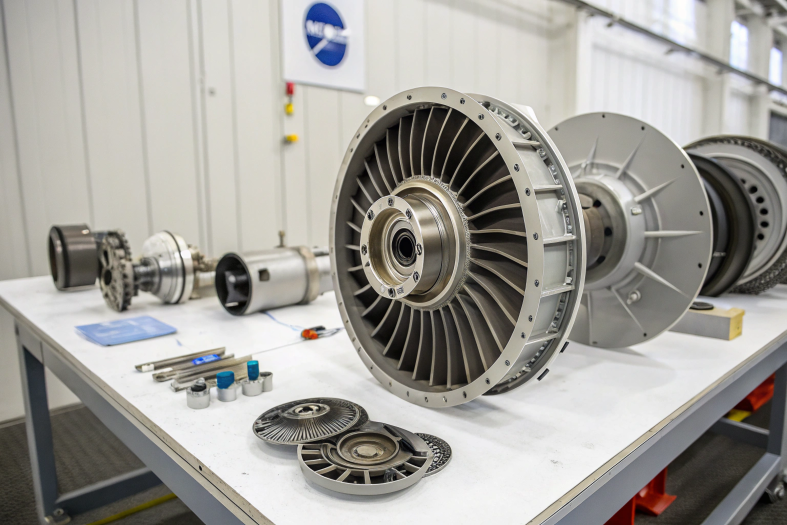

Boeing - Aerospace Prototypes

In the aerospace industry, where precision and material performance are critical, CNC machining plays a key role in prototyping parts such as turbine blades, structural components, and airframe sections. For instance, Boeing uses CNC machining to prototype engine components that require exact tolerances and superior material strength to ensure they perform under extreme conditions. The ability of CNC machines to handle complex geometries and work with advanced materials like titanium and high-performance alloys makes them indispensable for developing prototypes that must meet rigorous industry standards. -

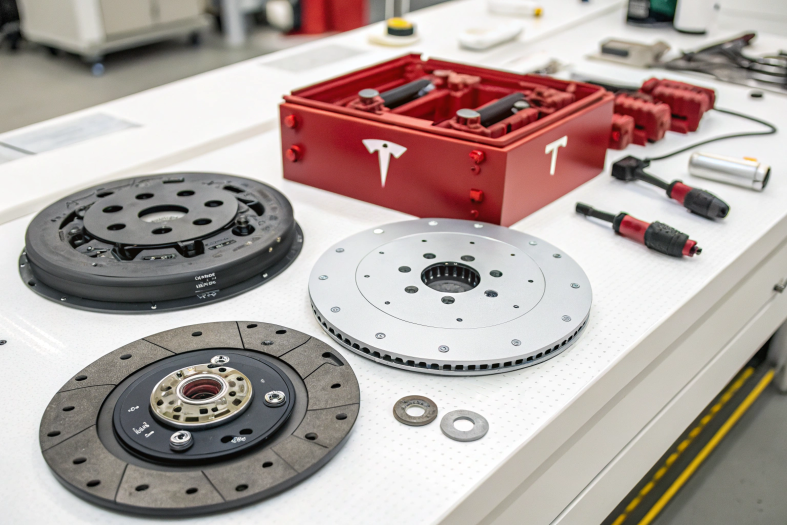

Tesla - Automotive Components

Tesla, known for its electric vehicles, relies heavily on CNC machining to prototype various automotive parts, including engine components, suspension systems, and battery housings. These parts need to be tested for fit, performance, and durability, and CNC machining offers the precision and material versatility to produce functional prototypes that mimic the final product. For example, Tesla uses CNC machining to create prototypes of battery enclosures to ensure they fit within the vehicle’s design and meet thermal and structural performance requirements. -

Stryker - Medical Device Prototyping

Stryker, a global leader in medical technologies, uses CNC machining for prototyping medical devices such as orthopedic implants, surgical instruments, and spinal components. These devices require high precision, as any deviation in size or fit could result in significant safety and performance issues. CNC machining ensures that prototypes match the exact specifications needed for further testing and evaluation. In particular, titanium and other biocompatible materials are commonly used, and CNC machining can handle these materials with ease, producing prototypes that closely resemble the final production units. -

General Motors (GM) - Automotive Engineering

General Motors uses CNC machining for prototyping various automotive components such as engine blocks, gearboxes, and suspension parts. These prototypes are rigorously tested for performance, durability, and safety before mass production. CNC machining’s ability to produce precise, functional prototypes that can undergo real-world testing makes it an essential tool for GM in the development of new vehicle models. The prototypes are tested for fit, performance, and endurance, ensuring that the final design will meet consumer and regulatory standards. -

Medtronic - Surgical Instruments

Medtronic, a global leader in medical devices, uses CNC machining to produce prototypes of highly complex surgical instruments. For example, surgical tools such as catheter devices, biopsy needles, and robotic surgical arms require precision engineering to ensure they function correctly during medical procedures. CNC machining allows Medtronic to rapidly prototype and test these tools, ensuring they meet exact specifications and pass the necessary regulatory tests for safety and performance. CNC machining's ability to work with high-precision materials, including stainless steel and specialized alloys, makes it ideal for the medical device industry. -

SpaceX - Space Components

SpaceX, the private aerospace company led by Elon Musk, uses CNC machining to prototype critical components for their rockets, including engine parts, rocket nozzles, and structural elements. CNC machining enables SpaceX engineers to produce highly detailed, durable parts that undergo rigorous testing for extreme conditions, including high pressure and temperature changes during launch and flight. The precision and consistency of CNC machining ensure that these prototypes will perform as expected during actual missions. -

Apple - Consumer Electronics Prototypes

Apple uses CNC machining for prototyping parts of its consumer electronics, such as aluminum enclosures for iPhones and MacBooks. The sleek, minimalist design of Apple products demands precise machining to ensure that parts fit together seamlessly. CNC machining allows Apple’s engineers to produce prototypes quickly, test them for functionality, and refine their designs before mass production. The surface finish quality provided by CNC machines also helps meet Apple's high standards for product aesthetics.

Summary

These examples illustrate that CNC machining is widely used across diverse industries to produce high-precision prototypes that are crucial for testing, evaluation, and refinement. Whether in aerospace, automotive, medical devices, or consumer electronics, CNC machining’s ability to produce functional, accurate, and material-specific prototypes makes it an essential tool for companies looking to bring their innovative ideas to life. The real-world applications of CNC machining for prototyping are testament to its effectiveness and versatility, ensuring that products meet stringent industry standards and perform reliably in real-world conditions.

Conclusion and Recommendations

CNC machining remains a powerful and highly effective method for prototyping, offering precision, material versatility, and the ability to create functional prototypes. It is ideal for industries that require high accuracy and real-world performance testing, such as aerospace, automotive, and medical devices. While the costs and lead times can be higher than other methods like 3D printing, CNC machining's ability to produce durable, precise, and high-performance parts makes it invaluable for prototyping in complex and critical applications.

For companies focused on rapid prototyping, lower-volume production, or high-precision requirements, CNC machining is a preferred option. However, if cost or speed is a higher priority, especially for simple prototypes, methods like 3D printing might be more suitable. Ultimately, businesses should carefully evaluate their needs—considering factors like material, complexity, lead time, and performance testing—when choosing the most appropriate prototyping technique.

FAQ:

What is CNC machining good for?

CNC machining is good for producing high-precision, complex parts with tight tolerances, especially in industries like aerospace, automotive, and medical devices.

What is a CNC prototype?

A CNC prototype is a functional, high-precision model of a part or product created using CNC machines for testing and evaluation before mass production.

Is CNC good for batch production?

Yes, CNC machining is good for batch production as it provides consistent quality and precision for medium to large runs of parts.

What is the biggest disadvantage of using CNC?

The biggest disadvantage of CNC machining is its higher initial setup cost and longer lead times compared to some other manufacturing methods like 3D printing.