CNC technology transforms traditional machining into precision-driven manufacturing through automation and digital control^1

CNC, or Computer Numerical Control, refers to a manufacturing process where machines follow programmed instructions to create precise parts.

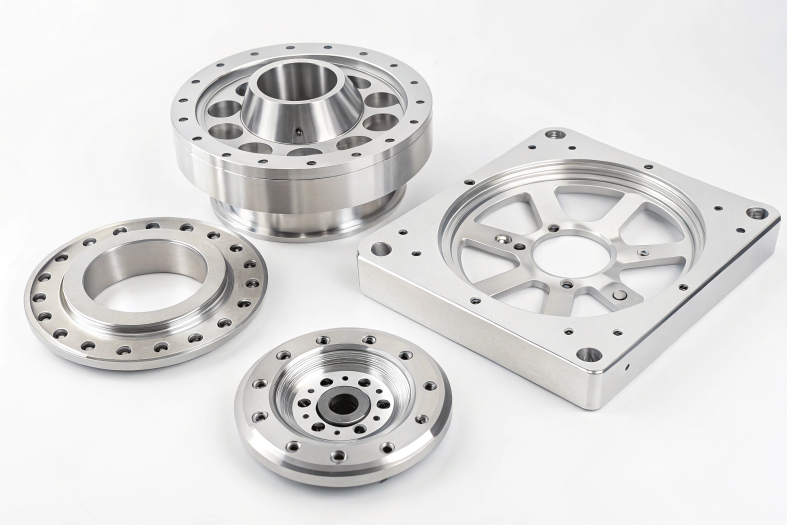

Discover how CNC machines redefine precision and productivity in modern manufacturing.

What Is a CNC Machining Center?

CNC machining centers are advanced manufacturing machines equipped with automated tools that perform multiple machining operations in one setup.

A CNC machining center is a multi-functional machine capable of milling, drilling, and cutting with high precision and efficiency.

Features of CNC Machining Centers

CNC machining centers offer unparalleled precision, speed, and versatility in part production.^2

Here's what makes them essential:

Key Features:

- Multi-Axis Operation: Machines can work on multiple axes simultaneously.

- Automatic Tool Changer (ATC): Reduces manual labor and increases productivity.

- High Precision: Achieves tight tolerances up to ±0.001 mm.

| Feature | Function | Benefit |

|---|---|---|

| Multi-Axis Capability | Complex part machining | Reduced part handling |

| Automatic Tool Change | Fast tool switching | Increased productivity |

| Precision Control | Digital accuracy | Consistent quality |

What Is a CNC Lathe?

A CNC lathe is a computer-controlled machine used for shaping cylindrical parts through cutting, drilling, and turning.

CNC lathes are ideal for creating precision components like shafts, bushings, and fittings through automated turning processes.

Benefits of CNC Lathes

CNC lathes excel in producing highly accurate, cylindrical parts with consistent quality.^3

Why Choose CNC Lathes?

- Precision Turning: Achieves smooth finishes.

- Speed & Efficiency: Handles large batches with ease.

- Versatility: Supports various materials like metals, plastics, and composites.

| Operation | Description | Result |

|---|---|---|

| Turning | Rotates material | Precise cylindrical shapes |

| Drilling | Creates holes | Accurate dimensions |

| Threading | Cuts threads | Custom fasteners |

What Is a CNC Grinder?

A CNC grinder uses rotating grinding wheels to remove material, achieving ultra-fine finishes and precision shaping.

CNC grinders are used for finishing and shaping parts by removing minimal material with precision grinding wheels.

Advantages of CNC Grinding

CNC grinders offer precise surface finishing for complex and delicate parts^4

Key Applications:

- Tool Sharpening: Keeps cutting tools precise.

- Surface Finishing: Achieves smooth, flawless surfaces.

- Component Shaping: Ensures precision dimensions for critical parts.

| Application | Use Case | Advantage |

|---|---|---|

| Surface Grinding | Metal polishing | High-quality finishes |

| Cylindrical Grinding | Shaft manufacturing | Accurate dimensions |

| Tool Grinding | Tool sharpening | Increased tool lifespan |

What Is a CNC Code?

CNC codes are digital instructions that guide machine movements, specifying operations like cutting, drilling, and shaping.

CNC code, written in G-code or M-code, tells machines how to perform specific tasks such as positioning, cutting, and speed adjustments.

Understanding CNC Codes

CNC codes form the language machines understand, translating design into action.

Common CNC Codes:

- G-Code: Controls movement (e.g., cutting paths).

- M-Code: Manages auxiliary functions (e.g., coolant control).

- Coordinate System: Defines machine reference points for precise positioning.

CNC Lathe G-Codes (G1 - G99)

| G-Code | Description |

|---|---|

| G01 | Linear Interpolation |

| G02 | Circular Interpolation (CW) |

| G03 | Circular Interpolation (CCW) |

| G04 | Dwell |

| G20 | Input in Inches |

| G21 | Input in Millimeters |

| G28 | Return to Reference Point |

| G32 | Thread Cutting (Single-Start) |

| G34 | Thread Cutting (Variable Lead) |

| G40 | Cancel Tool Radius Compensation |

| G41 | Tool Radius Compensation Left |

| G42 | Tool Radius Compensation Right |

| G50 | Coordinate Setting / Max Spindle Speed |

| G70 | Finish Machining Cycle (with G71/G72) |

| G71 | OD/ID Rough Turning Cycle |

| G72 | Facing Rough Turning Cycle |

| G73 | Pattern Repeating Cycle |

| G74 | Face Drilling Cycle (Reverse Feed) |

| G75 | Grooving Cycle (Face) |

| G76 | Precision Threading Cycle (Multi-Start) |

| G80 | Cancel Fixed Cycle |

| G90 | Absolute Programming Mode |

| G92 | Setting Work Coordinate System / Thread Start Point |

| G94 | Feed per Minute (for live tooling) |

| G95 | Feed per Revolution |

| G96 | Constant Surface Speed Control (CSS) |

| G97 | Constant Spindle Speed |

CNC Lathe M-Codes (M1 - M99)

| M-Code | Description |

|---|---|

| M00 | Program Stop |

| M01 | Optional Stop |

| M03 | Spindle On (CW) |

| M04 | Spindle On (CCW) |

| M05 | Spindle Stop |

| M08 | Coolant On |

| M09 | Coolant Off |

| M19 | Spindle Orientation |

| M30 | Program End and Reset |

| M98 | Call Subprogram |

| M99 | End of Subprogram/Loop |

Machining Center G-Codes (G1 - G99)

| G-Code | Description |

|---|---|

| G01 | Linear Interpolation |

| G02 | Circular Interpolation (CW) |

| G03 | Circular Interpolation (CCW) |

| G04 | Dwell |

| G09 | Exact Stop Check (Non-modal) |

| G10 | Data Setting (e.g., Offset Input) |

| G17 | XY Plane Selection |

| G18 | XZ Plane Selection |

| G19 | YZ Plane Selection |

| G20 | Input in Inches |

| G21 | Input in Millimeters |

| G28 | Return to Reference Point |

| G29 | Return from Reference Point |

| G30 | Return to Second/Third/Fourth Ref. Pt. |

| G31 | Skip Function (e.g., Probe) |

| G40 | Cancel Tool Radius Compensation |

| G41 | Tool Radius Compensation Left |

| G42 | Tool Radius Compensation Right |

| G43 | Tool Length Compensation (Positive) |

| G44 | Tool Length Compensation (Negative) |

| G49 | Cancel Tool Length Compensation |

| G50 | Coordinate Setting/Scaling (Varies) |

| G51 | Scaling |

| G52 | Local Coordinate System Setting |

| G53 | Use Machine Coordinate System |

| G54~G59 | Work Coordinate System Selection |

| G61 | Exact Stop Mode |

| G64 | Continuous Cutting Mode (Cancel G61) |

| G65 | Macro Call |

| G66 | Modal Macro Call |

| G67 | Cancel Modal Macro Call |

| G68 | Coordinate Rotation |

| G69 | Cancel Coordinate Rotation |

| G73 | High-Speed Peck Drilling (Shallow Holes) |

| G74 | Left-Hand Tapping (Reverse Tapping) |

| G76 | Fine Boring Cycle (Varies) |

| G80 | Cancel Fixed Cycle |

| G81 | Drilling Cycle |

| G82 | Drilling Cycle with Dwell |

| G83 | Peck Drilling (Deep Hole) |

| G84 | Tapping Cycle (Right-Hand) |

| G85 | Boring Cycle (Feed In, Feed Out) |

| G86 | Boring Cycle (Feed In, Stop, Rapid Out) |

| G87 | Back Boring Cycle (From Bottom Up) |

| G88 | Boring Cycle (Manual Retract) |

| G89 | Boring Cycle (Feed In, Feed Out, Dwell) |

| G90 | Absolute Programming Mode |

| G91 | Incremental Programming Mode |

| G92 | Coordinate System Setting |

| G94 | Feed per Minute |

| G95 | Feed per Revolution |

| G96 | Constant Surface Speed Control (CSS) |

| G97 | Constant Spindle Speed |

| G98 | Return to Initial Plane (Drill Cycle) |

| G99 | Return to R-Plane (Drill Cycle) |

Machining Center M-Codes (M1 - M99)

| M-Code | Description |

|---|---|

| M00 | Program Stop |

| M01 | Optional Stop |

| M03 | Spindle On (CW) |

| M04 | Spindle On (CCW) |

| M05 | Spindle Stop |

| M06 | Tool Change (ATC) |

| M07 | Mist Coolant On |

| M08 | Flood Coolant On |

| M09 | Coolant Off |

| M19 | Spindle Orientation |

| M30 | Program End and Reset |

| M98 | Call Subprogram |

| M99 | End of Subprogram/Return |

Conclusion

CNC technology revolutionizes modern manufacturing by automating complex machining tasks with unparalleled precision and efficiency.

^1: Learn how automation enhances precision and efficiency in CNC-based manufacturing processes.

^2: Learn how CNC machining centers streamline production by handling multiple tasks simultaneously.

^3: Understand how CNC lathes maintain precision and quality in large-scale production.

^4: Discover how CNC grinders ensure flawless surface finishes even on intricate components.